DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic packing and seals manufacturer for pneumatic equipment

-

v s

1. DMS Seal Manufacturer is manufactured under standardized production conditions.

2. hydraulic packing and seals is trusted by customers because of their high quality and excellent performance.

3. Each step of DMS Seal Manufacturer hydraulic packing and seals production meets the international production specification.

4. DMS Seal Manufacturer features with reasonable structure and appealing design.

5. Only the materials that do no harm to health is used to manufacture DMS Seal Manufacturer .

6. This product has been approved by an authoritative third party, including performance, durability and reliability.

7. Products have passed the international quality certification, to ensure high quality products.

8. The product is highly praised and has a long service life.

9. Professional staff strictly check, to ensure that products always maintain the highest quality.

10. Once these shoes made of this material are on one's feet, they will feel the difference and know they are wearing something unique.

11. This product will remove the physical need of man, and created a society that has never been known to man.

12. The product is becoming increasingly popular because it protects people from harmful bacteria which may cause skin allergies.

13. With the trendy design, it will never be out of date and will always be used as a valuable and creative decoration element for space.

14. Personally speaking, it makes the individual look charm and vigorous and helps people increasingly focus on the desire for beauty.

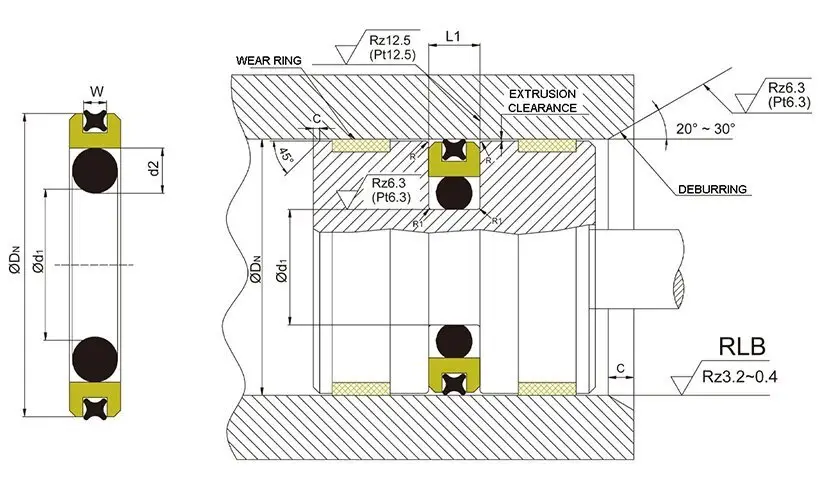

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Light Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

15 - 39.9 | 40 - 79.9 | DN - 11.0 | 4.2 | 1.0 | 0.25 | 0.15 | 0.10 | 3.53 | 1.78 |

40 - 79.9 | 80 - 132.9 | DN - 15.5 | 6.3 | 1.3 | 0.3 | 020 | 0.15 | 5.33 | 1.78 |

80 - 132.9 | 133 - 252.9 | DN - 21.0 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

133 - 252.9 | -- | DN - 24.5 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

253 - 462.9 | -- | DN - 28.0 | 9.5 | 2.5 | 0.45 | 0.30 | 0.25 | 8.40 | 3.53 |

463 - 700 | -- | DN - 35.0 | 11.5 | 3.0 | 0.55 | 0.40 | 0.35 | 10.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Recommended for double-acting pistons as piston-type energy storage, supporting cylinder and positional cylinder. Double safety with low friction and high elasticity, good dynamic and static sealing performance, larger extrusion clearances can be allowed, at the same time with the function of holding pressure, less leakage in the hydraulic cylinder. Simple groove, small installation space, excellent sliding performance, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-40MPa | -30℃+200℃ | 2 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

70 | 59 | 4.2 | DAQ70*59*4.2 | 56.74*3.53 |

80 | 64.5 | 6.3 | DAQ80*64.5*6.3 | 62.87*5.33 |

85 | 64 | 8.1 | DAQ85*64*8.1 | 63*7.0 |

95 | 79.5 | 6.3 | DAQ95*79.5*6.3 | 78.74*5.33 |

100 | 79 | 8.1 | DAQ100*79*8.1 | 78*7.0 |

110 | 94.5 | 6.3 | DAQ110*94.5*6.3 | 91.44*5.33 |

115 | 94 | 8.1 | DAQ115*94*8.1 | 93*7.0 |

125 | 109.5 | 6.3 | DAQ125*109.5*6.3 | 107.32*5.33 |

130 | 109 | 8.1 | DAQ130*109*8.1 | 108*7.0 |

150 | 129 | 8.1 | DAQ150*129*8.1 | 126.37*7.0 |

180 | 159 | 8.1 | DAQ180*159*8.1 | 158.12*7.0 |

210 | 189 | 8.1 | DAQ210*189*8.1 | 183.52*7.0 |

240 | 219 | 8.1 | DAQ240*219*8.1 | 215.27*7.0 |

Company Features

1. Since the founding, Dms Seals Technology Co.,limited has been engaged in designing, manufacturing, and supplying . We have become an experienced manufacturer in the industry. Dms Seals Technology Co.,limited is a major manufacturer and exporter of in China. What sets us apart in a crowded world market place is our extensive experience. Dms Seals Technology Co.,limited has been acting as a specialist for designing, manufacturing, marketing of and we have earned a sound reputation in the industry. Dms Seals Technology Co.,limited is one of the most dynamic companies in the complex world of manufacturing.

2. Dms Seals Technology Co.,limited highly values the introduction of cutting edge technology and advanced production equipment. Dms Seals Technology Co.,limited is a reliable supplier for its high quality of hydraulic packing and seals . DMS Seal Manufacturer is a developing company which dominates the hydraulic seals & supplies inc industry.

3. Sustainability is one of our company's strategic business objectives. We have paid close attention to our energy consumption and have worked on the following specific projects: replacing lighting, identifying very large power consumers in our processes, etc. Our firm bears societal responsibilities. We are always focusing on boosting the eco-efficiency of the business by providing the right technology. Our company is getting leaner and greener faster than ever. We made efforts in sustainable manufacturing that focuses on waste prevention, environmental impacts, worker health, and safety.

DMS Seal Manufacturer hydraulic packing and seals manufacturer for pneumatic equipment

hydraulic packing and seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US