DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic oil seal manufacturers for business for pneumatic equipment

1. In terms of materials, DMS Seal Manufacturer offers a variety of possible options. These high-quality materials are purchased from local reliable suppliers. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

2. It does contribute to the reduction of operating costs for homeowners or business owners. Owing to its energy efficiency, it helps save a lot on energy expenditures. The high pressure seals have strong wear resistance to hard conditions

3. The filler material does not penetrate through its high-quality fabric after long periods of using and multiple washing. DMS Seals' production equipment and test equipment are on the leading level in the industry

4. The product operates reliably under harsh conditions. It is not affected by severe weather conditions such as lightning and strong storms and is not affected by high temperature and humid conditions. Our products mainly include rod seals, piston seals, scraper seals, rotary seals, rubber seal products and spring seals

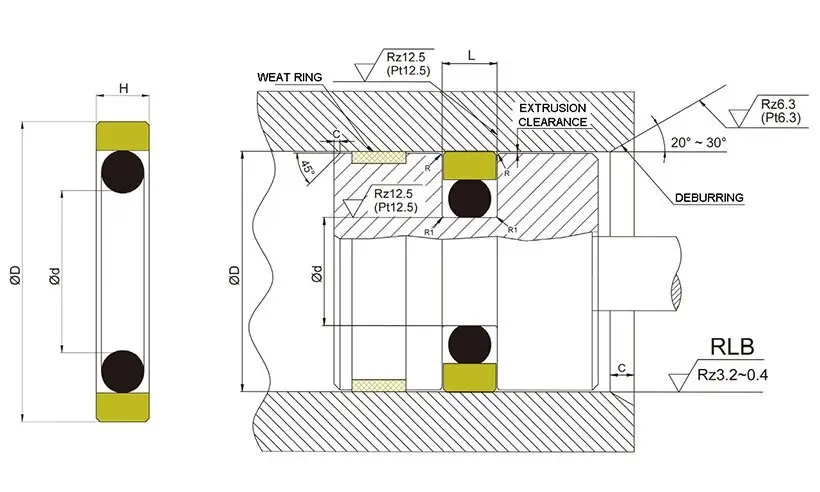

Application and properties

Standard double acting sealing, a wide range of applications. Friction resistance is very low, no crawling phenomenon, strong wear resistance, and saving installation space.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-35MPa | -30℃+200℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others. |

Nominal Size of Packing, and Housing dimensions | L +0.2 | Order No. | ||

D | d | H | ||

20 | 14 | 3 | 3.2 | DPO20*14*3.2 |

31.5 | 23 | 3.8 | 4 | DPO31.5*23*4 |

35.5 | 27 | 3.8 | 4 | DPO35.5*27*4 |

50 | 41.5 | 3.8 | 4 | DPO50*41.5*4 |

56 | 47.5 | 3.8 | 4 | DPO56*47.5*4 |

65 | 51 | 6.3 | 6.5 | DPO65*51*6.5 |

75 | 61 | 6.3 | 6.5 | DPO75*61*6.5 |

90 | 76 | 6.3 | 6.5 | DPO90*76*6.5 |

105 | 91 | 6.3 | 6.5 | DPO105*91*6.5 |

115 | 101 | 6.3 | 6.5 | DPO115*101*6.5 |

130 | 116 | 6.3 | 6.5 | DPO130*116*6.5 |

150 | 136 | 6.3 | 6.5 | DPO150*136*6.5 |

180 | 160 | 9.8 | 10.0 | DPO180*160*10 |

Company Features

1. With strong technical expertise and advanced management, Dms Seals Technology Co.,limited produces many kinds of hydraulic oil seal manufacturers .

2. As long as Dms Seals Technology Co.,limited sticks to the scientific principles of , we will be able to ensure that we will seize the forefront in hydraulic seal kit manufacturers industry. Ask online!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US