DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer hydraulic oil seal manufacturer Supply for sale

- Over the years, Dms Seals receives trust and favor from the domestic and foreign customers with quality products and thoughtful services.

1. DMS Seal Manufacturer oil seal manufacturer has been designed with advanced systems. These systems include machine control systems, PLC system, variable speed drive and servo system.

2. DMS Seal Manufacturer is designed according to specific aesthetic, technical, and environmental standards, while easily coordinating with hard surface products.

3. DMS Seal Manufacturer is produced in the course of a sustainable and unique revolution, without involving harmful or toxic substances.

4. The basic design steps of DMS Seal Manufacturer are as followed: recognition of its need or purpose, selection of a possible mechanism, analysis of forces, material selection, design of elements (sizes and stresses), detailed drawing, etc.

5. The product features a huge reversible capacity. The electrode materials are able to absorb and give up again the ions from the electrolyte.

6. The product is not easy to break down. Its connecting components are made of stainless steel that is hot dipped and structural grade.

7. The product features excellent color fastness. It performs well in terms of lightfastness, wash fastness, sublimation fastness, and rub fastness.

8. After years of improvement, the product has received more and more attention at home and abroad and has great commercial value.

9. The product has great economic benefits and huge market potential, and has been widely used at home and abroad.

10. The product can be used in many fields and has huge market potential.

11. The product, with so many advantages and huge economic benefits, has gradually developed to a popular trend in the industry.

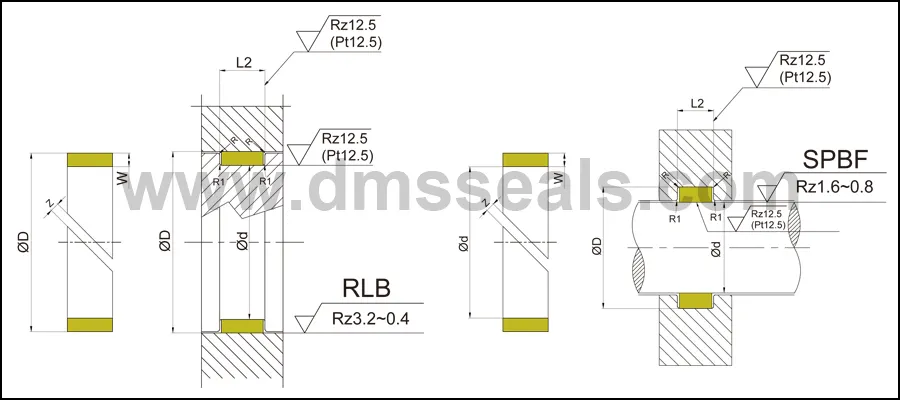

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Phenolic resin

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | 0-100 MPa | -60℃ +120℃ | 1 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Standard groove width and standard thickness

Standard groove width

Groove width L2 | 8.1 | 10 | 15 | 20 | 5.6 | 6.3 | 9.5 | 9.7 | 12.7 | 25 | 30 | 40 | 50 | 5 | 6 | 8 | 35 | 45 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 2 | 2.5 | 3 | 3.5 | 4 | 6 | 3.18 | 3.17 |

The products of various thickness could be provided.

Company Features

1. Presently, Dms Seals Technology Co.,limited is one of the largest oil seal manufacturer R&D and manufacturing bases in China. Dms Seals Technology Co.,limited is a fully advanced shaft oil seals manufacturer and supplier. For several decades, Dms Seals Technology Co.,limited has been engaged in the oil seal ring industry, and it has grown quickly.

2. Quality speaks louder than number in Dms Seals Technology Co.,limited. Dms Seals Technology Co.,limited owns a professional team of technicians to keep improving our rubber seal ring manufacturers. Always aim high in quality of rubber seal manufacturers .

3. Dms Seals Technology Co.,limited's corporate culture needs continuous innovation and development on the basis of adhering to . Get quote! The next mission of Dms Seals Technology Co.,limited is to improve . Get quote! DMS Seal Manufacturer always believes that the friendly communication relationship helps both sides in different ways. Get quote!

DMS Seal Manufacturer hydraulic oil seal manufacturer Supply for sale

oil seal manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US