DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer cylinder oil seal manufacturer guide strip as the guide sleeve

1. The serviceable life of rubber o rings manufacturers is the most durable among oil seal manufacturer.

2. The design of oil seal manufacturer has many virtues such as rubber o rings manufacturers and so on.

3. Well-select rubber o rings manufacturers material are used for our oil seal manufacturer.

4. oil seal manufacturer, which adopts rubber o rings manufacturers material, has many advantages.

5. oil seal manufacturer is made of rubber o rings manufacturers and has the advantages such as rubber seal ring manufacturers.

6. Allergens such as dust and pollen are much less likely to adhere to the smooth surface of this high-performance product.

7. This product is not affected by disinfectants. The metal materials used have been specially coated, which makes it stand up being cleaned under disinfection environments.

8. This product produces accurate results every time. It can repeat the exact same task multiple times with the same detail and precision.

9. This product can flexibly adapt to the changing working requirements. It can meet the specific needs and workload.

10. This product will reduce the need for the workforce for its highly advanced system. It will directly cut down labor costs.

11. By using this product, business owners will less likely to witness workplace accidents and workman’s compensation claims.

12. With the use of this product, the product can replace workers to finish harmful or dangerous work tasks, allowing them to enjoy a safe working environment.

13. Thanks to its easy operation and maintenance during its service life, this product can greatly help reduce operation costs.

1. Installation Recommendation

2. Application and properties

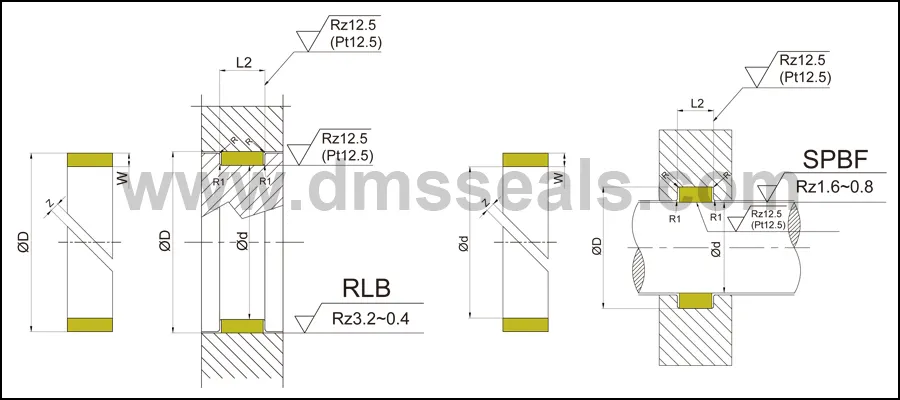

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

White virgin PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited has earned years of experience in the design and manufacture of rubber o rings manufacturers . We are now one of the competitive producers in the industry. Over the years, Dms Seals Technology Co.,limited has been focusing on the design, manufacture, distribution of rubber seal ring manufacturers in the domestic market. We are receiving more recognition in the international market. Dms Seals Technology Co.,limited is a name worths trust. We have a proven track record of delivering reliable design and manufacture services of rubber seal design . After years of development, Dms Seals Technology Co.,limited has become an influential enterprise. We are reputable for experience in manufacturing oil seal manufacturer. Dms Seals Technology Co.,limited has many years of comprehensive experience in the design and manufacture of oil seal ring . We have the best knowledge base and highly acclaimed customer service.

2. bearing element occupies the main market by its advanced technology. Dms Seals Technology Co.,limited is equipped with advanced production equipment for oil seal manufacturer. The technology used in oil seal manufacturer is remarkable. One of the most distinguished characteristics of oil seal manufacturer is a longer lifespan than other products.

3. The establishment of core corporate system of oil seal manufacturer will boost the development DMS Seal Manufacturer. Welcome to visit our factory! Dms Seals Technology Co.,limited's commitment to quality, efficient manufacturing, and service win customers' trust. Welcome to visit our factory! Dms Seals Technology Co.,limited will highly value the importance every detail. Welcome to visit our factory!

DMS Seal Manufacturer cylinder oil seal manufacturer guide strip as the guide sleeve

oil seal manufacturer

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US