DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer bronze piston seals for light and medium hydraulic systems

1. piston seals we quoted are all made of the best hydraulic cylinder piston seals and of various kinds of styles and colors in order to meet different requirements. DMS Seals implements and optimizes its quality control systems

2. Dms Seals Technology Co.,limited provides integrated and comprehensive solutions to its customers. Seal we produced has applications in a wide range of fields

3. The product has the desired energy efficiency. Its mechanical components and parts are designed by adopting low energy consumption technology, featuring low energy loss in operation. DMS Seals provides professional design and production of high-grade o-ring seals

4. The product is built to last. All of the electric components are manufactured with high quality and stable electric performance, which guarantees its aging resistance. We can support OEM and ODM

5. The product can run stably in rigorous conditions. The product is not affected by extreme weather conditions such as thunder lightning and heavy storm, nor high-temperature or humid condition. The high pressure seals have strong wear resistance to hard conditions

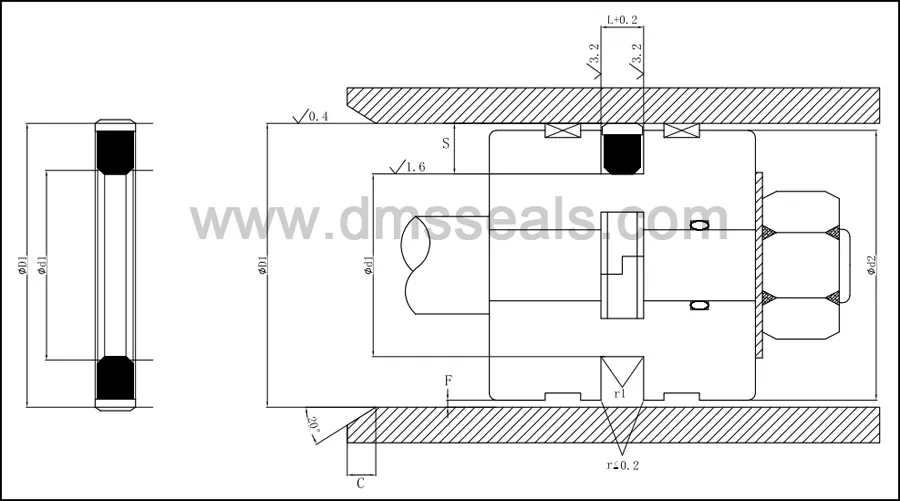

1. Installation Recommendation

2. Application and properties

Extreme wear resistance, easy installation on single-part piston without assembly aids due to the split design of the sealing ring. Assembly on one-part piston is possible. Insensitive to extreme pressure peaks. Extreme high extreme pressure resistance. High pressure an large gaps due to the special compound properties of the seal ring. Dimensions according to ISO 7425-1. Short axial assembly length. Installation in closed and undercut housings. Additional sizes of machined products available on short notice.

3. Standard materials

Sealing ring: filled modified thermoplast

O-ring: NBR

4. Working Conditions

Working Conditions | |||

Diameter Range | Pressure Range | Temperature Range | Speed |

25 - 480mm | 0 - 80MPa | -30℃ +110℃ | ≤1 m/s |

5. Installation Dimensions

D1 | d1 | L | |

25 32 40 | 16 21 26.3 | 4.2 4.2 5.8 | OK25*16*4.2 OK32*21*4.2 OK40*26.3*5.8 |

40 50 50 | 29 34.5 36.3 | 4.2 6.3 5.8 | OK40*29*4.2 OK50*34.5*6.3 OK50*36.3*5.8 |

50 50 55 | 37 39 44 | 8 4.2 4.2 | OK50*37*8 OK50*39*4.2 OK55*44*4.2 |

55 60 60 | 44 41.7 49 | 4.2 7 4.2 | OK55*44*4.2 OK60*41.7*7 OK60*49*4.2 |

63 63 63 | 44.7 47.5 52 | 7 6.3 4.2 | OK63*44.7*7 OK63*47.5*6.3 OK63*52*4.2 |

70 70 70 | 51.7 54.5 54.5 | 7 6.3 6.3 | OK70*51.7*7 OK70*54.5*6.3 OK70*54.5*6.3 |

70 75 75 | 59 54 59.5 | 4.2 8 6.3 | OK70*59*4.2 OK75*54*8 OK75*59.5*6.3 |

80 80 85 | 59 64.5 64 | 8 6.3 8 | OK80*59*8 OK80*64.5*6.3 OK85*64*8 |

90 90 95 | 69 74.5 74 | 8 6.3 8 | OK90*69*8 OK90*74.5*6.3 OK95*74*8 |

100 100 105 | 79 84.5 84 | 8 6.3 8 | OK100*79*8 OK100*84.5*6.3 OK105*84*8 |

110 110 115 | 89 94.5 94 | 8 6.3 8 | OK110*89*8 OK110*94.5*6.3 OK115*94*8 |

115 120 125 | 100 99 104 | 8 8 8 | OK115*100*8 OK120*99*8 OK125*104*8 |

125 130 130 | 109.5 109 114.5 | 6.3 8 6.3 | OK125*109.5*6.3 OK130*109*8 OK130*114.5*6.3 |

130 135 135 | 115 114 119.5 | 8 8 6.3 | OK130*115*8 OK135*114*8 OK135*119.5*6.3 |

140 140 145 | 119 125 124 | 8 8 8 | OK140*119*8 OK140*125*8 OK145*124*8 |

150 150 152.4 | 129 135 131.5 | 8 8 8 | OK150*129*8 OK150*135*8 OK152.4*131.5*8 |

160 160 165 | 139 148 144 | 8 8 8 | OK160*139*8 OK160*148*8 OK165*144*8 |

170 175 180 | 149 154 159 | 8 8 8 | OK170*149*8 OK175*154*8 OK180*159*8 |

190 200 210 | 169 179 189 | 8 8 8 | OK190*169*8 OK200*179*8 OK210*189*8 |

220 220 230 | 199 205 209 | 8 8 8 | OK220*199*8 OK220*205*8 OK230*209*8 |

240 250 260 | 225 229 239 | 8 8 8 | OK240*225*8 OK250*229*8 OK260*239*8 |

270 280 290 | 249 255.5 271 | 8 8 9.5 | OK270*249*8 OK280*255.5*8 OK290*271*9.5 |

300 320 330 | 272 292 302 | 9.5 9.5 9.5 | OK300*272*9.5 OK320*292*9.5 OK330*302*9.5 |

350 370 420 | 322 342 392 | 9.5 9.5 9.5 | OK350*322*9.5 OK370*342*9.5 OK420*392*9.5 |

450 480 | 422 452 | 9.5 9.5 | OK450*422*9.5 OK480*452*9.5 |

Company Features

1. Dms Seals Technology Co.,limited has been specializing in the manufacture of piston seals for many years. We have adopted the latest fabrication and processing technology to adapt to changing market conditions and customer demands.

2. DMS Seal Manufacturer has intellectually great technical power to produce hydraulic piston seals with finest quality.

3. Dms Seals Technology Co.,limited wishes bright and creative talents to work with us! Contact us!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US