DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer best mechanical seal operation supplier for larger piston clearance

1. The materials of DMS Seal Manufacturer are sourced from suppliers that enforce strict social standards in their factories.

2. As for the design of mechanical seal operation , it is of great popularity now.

3. The materials of DMS Seal Manufacturer mechanical seal operation are sourced strictly according to the production plan.

4. It is safe to use. Its housing materials, as well as the electric parts, are well inspected to eliminate all of the toxic substances.

5. The product is less likely to leak. It is finely sealed with good materials which effectively hide its electrolyte inside.

6. This product can realize many special architectural performance techniques, mainly in the form of styling, diffuse light transmission, and rich color.

7. With innovative mechanical seal operation products and creative advantages, Dms Seals Technology Co.,limited shows the charm of art.

8. It’s no accident that excellent customer service of Dms Seals Technology Co.,limited comes from a highly trained staff.

9. Dms Seals Technology Co.,limited has a complete sales network and perfect after-sales service system.

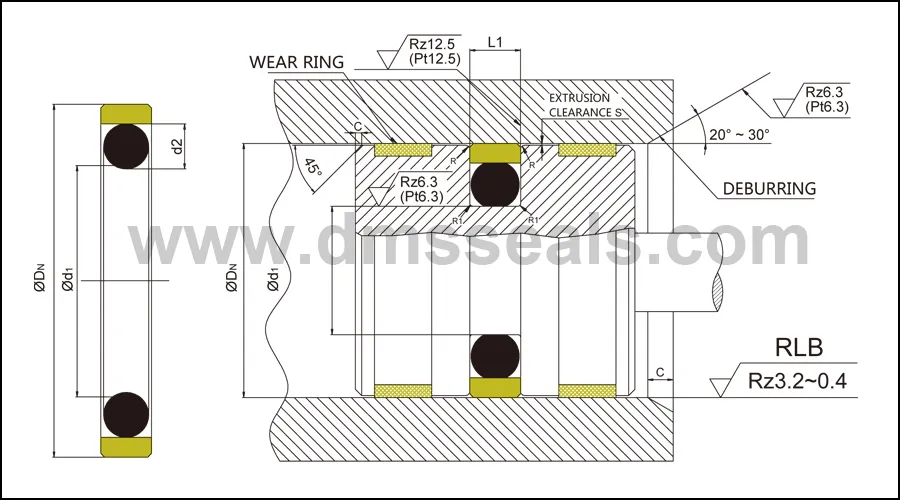

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited has engaged in R&D, production, sales and after-sales service of mechanical seal operation products for decade of years. Dms Seals Technology Co.,limited walks in the forefront of glyd ring field in China. DMS Seal Manufacturer is quality-oriented and has gained wide market in hydraulic cylinder piston seals field.

2. Always aim high in quality of viton oil seal manufacturers . Staff working in Dms Seals Technology Co.,limited are all well-trained. We put great emphasis on technology of molded rubber seals . Our quality is our company name card in oil seal manufacturers industry, so we will do it best. Our hydraulic oil seal manufacturers is easily operated and need no additional tools.

3. Our company strives for service excellence. We apply our expertise to enhance the customer's business and provide solution designed with only customers in mind. We regard customer satisfaction as a core part of our business. We aim to exceed our customers' expectations while meeting their needs and providing professional services. Years of solid development have provided us a very clear notion: be innovative and hungry for development. We will continue to enhance our R&D ability by exploiting the power of advanced and technologies, as well as the keen insight into market trends. We bear social responsibilities. We continually evaluate our business practices to determine how health, environmental and safety standards are impacted and make concerted efforts to improve. We have set out to increase our positive impact on the environment. We strive to ensure that we source our ingredients responsibly and sustainably.

DMS Seal Manufacturer best mechanical seal operation supplier for larger piston clearance

mechanical seal operation

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US