DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

bronze o-ring seal with ptfe nbr and pom for light and medium hydraulic systems

1. Fabrics check of DMS Seal Manufacturer hydraulic cylinder piston seals will cover a few aspects. The fabric width, length, appearance (weaving quality, splices, odors), safety, and properties are all checked to comply with the relevant standards and regulations.

2. DMS Seal Manufacturer hydraulic cylinder piston seals goes through a range of production processes, including materials cleaning, drilling, laser cutting, extruding, engraving, surface polishing, and quality inspection.

3. During the design phase, several factors of DMS Seal Manufacturer hydraulic cylinder piston seals have been taken into account. They include structural&visual balance, symmetry, unity, variety, hierarchy, scale, and proportion.

4. DMS Seal Manufacturer hydraulic cylinder piston seals is designed after designers have considered various elements. They involve foot proportion & shape, weight distribution, pressure point of the arch, and features of physiological structure development.

5. The design of DMS Seal Manufacturer o-ring seal is knowledge-intensive. It is closely related to social sciences and natural sciences such as literature, art, philosophy, aesthetics, psychology, physiology, and ergonomics.

6. The surface of this product appears to be smooth and consistent. It has been finely polished and removed all the defections such as burrs.

7. The product is safe to use. It has been checked under anti-static testing and materials elements inspection to ensure users' safety.

8. The product is characterized by its excellent colorfastness. It will not fade in terms of washing, seawater, chlorinated water, perspiration, and hydrolysis.

9. It has established a deeper connection with prospective buyers.

10. Dms Seals Technology Co.,limited's team members are willing to make changes, remain open to new ideas and respond rapidly.

11. It brings considerable profitability and brand influence to DMS Seal Manufacturer.

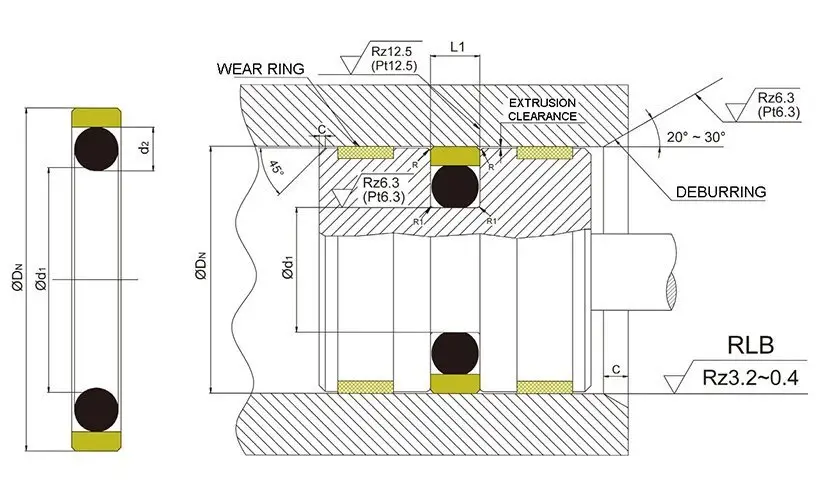

2.Application and properties

Standard double acting sealing, a wide range of applications. Friction resistance is very low, no crawling phenomenon, strong wear resistance, and saving installation space.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-35MPa | -30℃+200℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others. |

Bore Dia. | Groove Width | Order No. | O-Ring Dimension |

D H9 | L1+0.2 | ||

60 | 6 | SPGO60*6 | 43.5*5.3 |

75 | 6 | SPGO75*6 | 58*5.3 |

90 | 6 | SPGO90*6 | 73*5.3 |

105 | 6 | SPGO105*6 | 87.5*5.3 |

120 | 6 | SPGO120*6 | 103*5.3 |

135 | 6 | SPGO135*6 | 118*5.3 |

150 | 6 | SPGO150*6 | 132.72*5.3 |

165 | 6 | SPGO165*6 | 148.5*5.3 |

180 | 6 | SPGO180*6 | 164.47*5.3 |

195 | 6 | SPGO195*6 | 177.17*5.3 |

90 | 7.9 | SPGO90*7.9 | 66*7 |

105 | 7.9 | SPGO105*7.9 | 82*7 |

Company Features

1. Dms Seals Technology Co.,limited is a leading o-ring seal supplier dedicated to manufacturing. Dms Seals Technology Co.,limited is internationally renowned in the field of hydraulic piston seals . Dms Seals Technology Co.,limited is a world market leader in piston seals .

2. As a core value of DMS Seal Manufacturer, the position of o-ring seal manufacture technology has been highly valued. The efforts of improving the quality of o-ring seal has been paid. Dms Seals Technology Co.,limited owns a group of experienced processing engineers and designers.

3. Depending on the relationships we have with our suppliers, we are committed to responsible, sustainable practices extending to every facet of our business. We endorse low carbon development. We will shape low-carbon culture internally and image as a leading provider of low-carbon solutions externally. During our production, we always keep costs and environmental considerations in mind. We make efforts to minimize energy consumption and waste, meeting the standards of environmental standards.

bronze o-ring seal with ptfe nbr and pom for light and medium hydraulic systems

o-ring seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US