DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

40% Bronze Filled PTFE Hydraulic Rod Seal Hydraulic Seal Suppliers1

1. The manufacture of DMS Seal Manufacturer piston o ring involves some critical processes. These stages include concept confirmation, metal materials procurement, frame fabrication, components machining, surface painting, and final assembly. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

2. Doctors have recommended this product because of proven relief from sports injury, chronic fatigue syndrome, fibromyalgia, arthritis, and other chronic pain conditions. The high pressure seals have strong wear resistance to hard conditions

3. The product is promised with high quality and long service life. We have developed solutions of the sealing of special working condition

4. Good properties of piston o ring are main advantages for hydraulic oil seal . Seal we produced has applications in a wide range of fields

5. The product is extensively appreciated by our clients for features like superior performance, longer service life, and so on. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

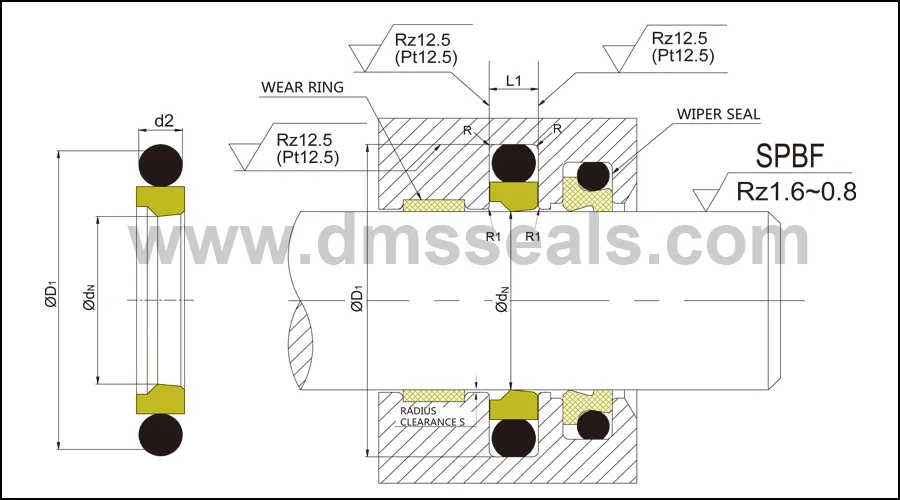

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation.

Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

4 5 6 | 8.9 9.9 10.9 | 2.2 2.2 2.2 | GSJ4*8.9*2.2 GSJ5*9.9*2.2 GSJ6*10.9*2.2 | 5.28*1.78 6.75*1.78 7.65*1.78 |

8 8 10 | 12.9 15.3 14.9 | 2.2 3.2 2.2 | GSJ8*12.9*2.2 GSJ8*15.3*3.2 GSJ10*14.9*2.2 | 9.25*1.78 10.77*2.62 11.8*1.78 |

10 12 12 | 17.3 16.9 19.3 | 3.2 2.2 3.2 | GSJ10*17.3*3.2 GSJ12*16.9*2.2 GSJ12*19.3*3.2 | 12.37*2.62 13.3*1.78 13.94*2.62 |

14 14 15 | 18.9 21.3 19.9 | 2.2 3.2 2.2 | GSJ14*18.9*2.2 GSJ14*21.3*3.2 GSJ15*19.9*2.2 | 15.6*1.78 15.54*2.62 16.67*1.78 |

15 16 16 | 22.3 20.9 23.3 | 3.2 2.2 3.2 | GSJ15*22.3*3.2 GSJ16*20.9*2.2 GSJ16*23.3*3.2 | 17.12*2.62 17.17*1.78 18.72*2.62 |

18 18 19 | 22.9 25.3 29.7 | 2.2 3.2 4.2 | GSJ18*22.9*2.2 GSJ18*25.3*3.2 GSJ19*29.7*4.2 | 18.77*1.78 20.29*2.62 23.39*3.53 |

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

Company Features

1. As the manufacturer of piston o ring , Dms Seals Technology Co.,limited is very professional. Each part of hydraulic cylinder piston seals will be checked by our professional QC department.

2. Dms Seals Technology Co.,limited has strong technical force and excellent equipment technology.

3. The professional excellent talents unite a powerful and creative team of design, research and development for Dms Seals Technology Co.,limited. In the future, Dms Seals Technology Co.,limited will focus on the innovative development of piston seals . Get price!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US