DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Wholesale piston lip seal manufacturers for pneumatic equipment

- Dms Seals has always been providing advanced technology and sound after-sales service for customers.

1. During the foot outline extraction stage of DMS Seal Manufacturer piston lip seal , the high-efficient, all-round, and customized CAD (computer-aided design) and CAM (computer-aided manufacturing) technology are used to guarantee the precision.

2. DMS Seal Manufacturer meets European fire safety specifications. It has tested and certified by appropriate institutions to meet the F90 class fire resistance requirements.

3. During the preliminary stage, DMS Seal Manufacturer has to go through the ore extraction process. This process includes several stages, namely, beneficiation, refine, and melt processes.

4. Wear and tear resistance is one of its biggest characteristics. The fibers used feature high fastness to rubbing and are not easy to break under severe mechanical abrasion.

5. This product is guaranteed with a high level of safety. There will not occur any electric leakage, poor insulation, and electric shock problems.

6. The product has a smooth and flat surface. The singeing technique which quickly passes yarn or fabric through a flame or rubs it over a hot metal surface to remove the surface hairs.

7. This product has excellent impact resistance. Its high compressibility and rebound resilience allow it to work under high-pressure mechanical movement.

8. Dms Seals Technology Co.,limited can take control of the whole process of piston lip seal manufacturing in its factory so quality is guaranteed.

9. DMS Seal Manufacturer is a company, dedicated to the design, develop and production of piston lip seal .

10. All of our piston lip seal comply with international quality standards and are greatly appreciated in a variety of different markets.

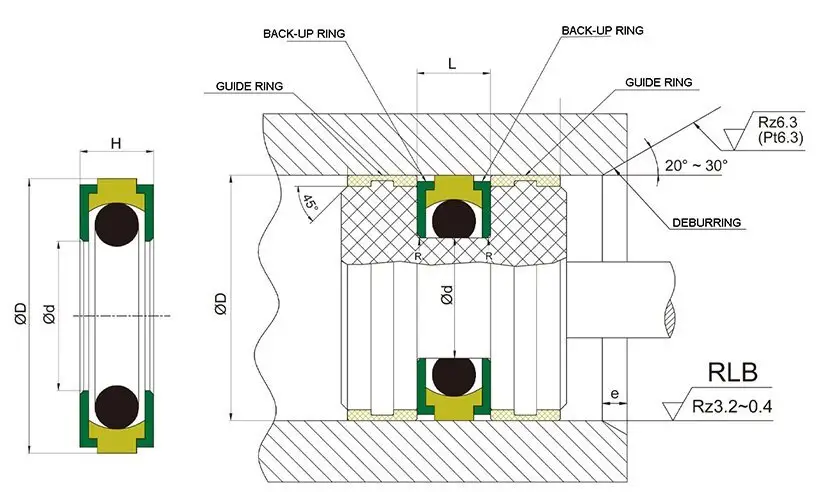

D H8 | d h9 | L+0.2 | H |

˂96 | D-16.3 | 8 | 7.5 |

96-190 | D-20 | 10 | 9.5 |

191-380 | D-28 | 13 | 12.5 |

381-1000 | D-36 | 20 | 19.5 |

Application and properties

Apply to hydraulic piston sealing, Consisting of a seal ring, two L-shaped POM back-up rings and an acting force O-Ring. The back-up ring acts as a support and guide to ensure a tight sealing environment. High wear resistance, low friction, no crawling phenomenon, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

L-Ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L | e | Order No. |

40 | 23.2 | 7.5 | 8 | 7 | DGDA40*23.2*7.5 |

56 | 39.2 | 7.5 | 8 | 7 | DGDA56*39.2*7.5 |

70 | 53.2 | 7.5 | 8 | 7 | DGDA70*53.2*7.5 |

85 | 68.2 | 7.5 | 8 | 7 | DGDA85*68.2*7.5 |

100 | 80 | 9.5 | 10 | 10 | DGDA100*80*9.5 |

115 | 95 | 9.5 | 10 | 10 | DGDA115*95*9.5 |

130 | 110 | 9.5 | 10 | 10 | DGDA130*110*9.5 |

145 | 125 | 9.5 | 10 | 10 | DGDA145*125*9.5 |

160 | 140 | 9.5 | 10 | 10 | DGDA160*140*9.5 |

190 | 170 | 9.5 | 10 | 10 | DGDA190*170*9.5 |

220 | 192 | 12.5 | 13 | 12 | DGDA220*192*12.5 |

Company Features

1. DMS Seal Manufacturer has made it known to every family. The skyrocketing sales of piston lip seal shows the increasing notability of DMS Seal Manufacturer. Dms Seals Technology Co.,limited enjoys a stable business in global markets for its custom oil seals . DMS Seal Manufacturer has become a well-known brand in rod seal installation field. Dms Seals Technology Co.,limited manufactures the most kinds of piston seal manufacturers with different styles.

2. Dms Seals Technology Co.,limited is in possess of a group professional and skilled technicians. Through leading technology, seals for hydraulic pumps has helped DMS Seal Manufacturer win the recognition and trust of customers. There is a full set of quality testing system to ensure quality of hydraulic seal design . DMS Seal Manufacturer has also introduced professional experts who are specialized in manufacturing wholesale oil seals . The advanced mechanical processing equipment and the complete modern management system are available in Dms Seals Technology Co.,limited's manufacturing plant.

3. We are committed to creating a culture which respects and values individual differences, a place where everybody feels comfortable being themselves and where their views are recognized and respected in truly inclusive business. Get info! As a major employer, we recognize that we have a duty to contribute to the wider economy, creating jobs, using local suppliers and supporting our clients in tackling local socio-economic issues. Get info! Dms Seals Technology Co.,limited always provides reliable to maintain long-term growth. Get info! Our company has implemented a universal process to achieve our sustainability goals of reducing greenhouse gas emissions, energy consumption, solid landfill waste, and water consumption. Get info!

Wholesale piston lip seal manufacturers for pneumatic equipment

piston lip seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US