DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Top spiral spring gasket Suppliers for aviation

- Dms Seals consistently adheres to the purpose to be sincere, true, loving and patient. We are dedicated to providing consumers with quality service. We exert ourselves to develop mutually beneficial and friendly partnerships with customers and distributors.

1. Right material is extremely critical for the production of spiral spring gasket .

2. Even with the high cost for superior raw material, Dms Seals Technology Co.,limited firmly believe good quality of spiral spring gasket is everything.

3. spiral spring gasket is made by which provides a number of advantages.

4. This product has good strength. Its powerful braided structure and pressed fiberboard resist tearing and piercing.

5. The antibacterial fabric of this product is free of any skin irritants. They are soft, supple and easy on all kinds of skin.

6. It is highly effective at wicking moisture to keep dry due to a combination of the material itself and the tight weave of the fabric.

7. The product has an accurate running function. It is designed with a precise control system that enables it to work consistently under the given instructions.

8. In order to achieve quality assurance for spiral spring gasket , Dms Seals Technology Co.,limited takes measure of .

9. Dms Seals Technology Co.,limited has established several service centers for overseas customers.

10. The quality assurance process plays an important role in the quality of spiral spring gasket .

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

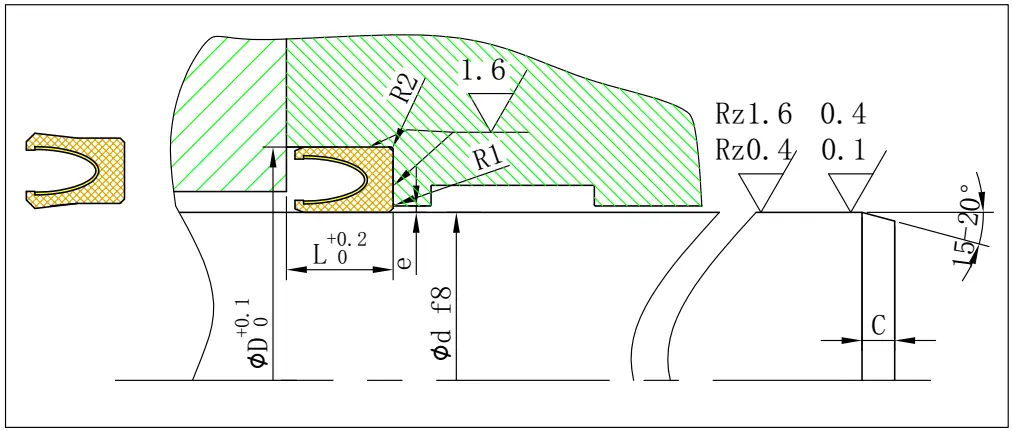

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is an experienced manufacturer. Over the years, we mainly focus on the developing, manufacturing, and exporting of . With years of devotion to developing and manufacturing , Dms Seals Technology Co.,limited is proud to gradually become stronger in this field. With years of continuous progress, Dms Seals Technology Co.,limited has become one of the leading enterprises in the developing and manufacturing of . After so many years of dedication in manufacturing , Dms Seals Technology Co.,limited becomes an expert and has the confidence to become a leader in this field.

2. Dms Seals Technology Co.,limited has strong scientific research and development capabilities. According to the requirements of customers, DMS Seal Manufacturer has introduced latest technology to produce spiral spring gasket . DMS Seal Manufacturer has made some breakthroughs in improving quality of the mechanical seal dimensions . Dms Seals Technology Co.,limited has a large number of domestic senior experts and professors for mechanical seal problems development.

3. DMS Seal Manufacturer has been constantly upgrading the quality of service for customers. Get quote! Dms Seals Technology Co.,limited's determined to keep our team and products perfect. Get quote! We can supply a abundant of mechanical seal arrangement with high quality. Get quote!

Top spiral spring gasket Suppliers for aviation

spiral spring gasket

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US