DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Top hydraulic u seal for business for sale

1. DMS Seal Manufacturer is manufactured under a range of state-of-the-art facilities. They are 1-Needle Lockstitch M/C, 1-Needle Chainstitch M/C, Zig-Zag Stitches M/C, Twin-Needle M/C, automatic cutting M/C, overlock machines, etc.

2. The designing for DMS Seal Manufacturer is exquisite. It reflects a strong craft tradition that is focused on utility and coupled with a human-centred design approach.

3. Rigorous quality inspection for DMS Seal Manufacturer is subject to conduct. It includes the examination of wearing resistance, bending, strength, rigidity, and anti-aging performance.

4. DMS Seal Manufacturer is created adopting state-of-the-art processing machines. They are CNC cutting&drilling machines, computer-controlled laser engraving machines, and polishing machines.

5. DMS Seal Manufacturer hydraulic u seal has been tested by the third-party testing organization. For example, it has passed fiber composition analysis, dimensional stability testing, shrinkage testing, stain resistance testing, and seam bursting testing.

6. The product features the desired wear resistance. Its coating provides enough lubrication to eliminate excessive wear and prevents the scoring, galling or sticking of components.

7. The product is corrosion resistant. It has been tested under salt mist, including neutral salt mist and acid-salt spray.

8. This product is safe to use. It is equipped with emergency protection systems such as short circuit, overload, overpressure, and voltage loss.

9. Its industrialization speed is fast, and its scale effect is remarkable.

10. In the industry, the domestic market share of Dms Seals Technology Co.,limited has always topped the list.

11. Dms Seals Technology Co.,limited has a knowledgeable talent team and a stable and reliable production line.

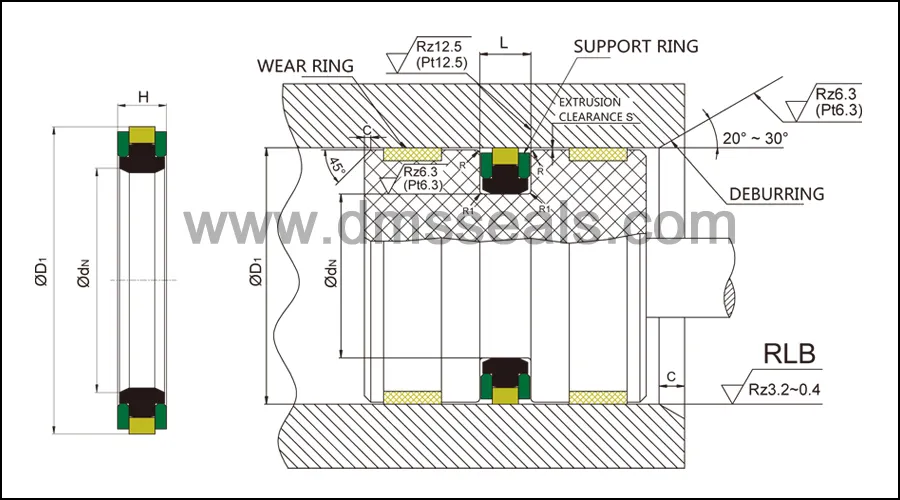

1. Installation Recommendation

2. Application and properties

Suitable for long stroke, a wide range of fluids and high temperature occasions. The application of heavy duty double acting piston sealing under high pressure conditions is excellent. Applicable to larger piston clearance , it has good leakage control, extrusion resistance and wear resistance in heavy duty and construction machinery cylinder piston sealing system. Good static sealing property, simple groove structure, larger extrusion clearances can be allowed, be able to work in dusty condition.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

50 - 350mm | 0 - 50MPa | -30℃ +100℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

Nominal Size of Packing, and Housing dimensions | L+0.2 | Order No. | ||

D1 | dN | H | ||

50 55 60 | 36 41 46 | 8.5 8.5 8.5 | 9 9 9 | SPGW50*36*8.5 SPGW55*41*8.5 SPGW60*46*8.5 |

63 65 70 | 48 50 55 | 10.5 10.5 10.5 | 11 11 11 | SPGW63*48*10.5 SPGW65*50*10.5 SPGW70*55*10.5 |

75 80 85 | 60 65 70 | 10.5 10.5 10.5 | 11 11 11 | SPGW75*60*10.5 SPGW80*65*10.5 SPGW85*70*10.5 |

90 95 100 | 75 80 85 | 10.5 10.5 12 | 11 11 12.5 | SPGW90*75*10.5 SPGW95*80*10.5 SPGW100*85*12 |

105 110 115 | 90 95 100 | 12 12 12 | 12.5 12.5 12.5 | SPGW105*90*12 SPGW110*95*12 SPGW115*100*12 |

120 125 130 | 105 102 107 | 12 15.5 15.5 | 12.5 16 16 | SPGW120*105*12 SPGW125*102*15.5 SPGW130*107*15.5 |

135 140 145 | 112 117 122 | 15.5 15.5 15.5 | 16 16 16 | SPGW135*112*15.5 SPGW140*117*15.5 SPGW145*122*15.5 |

150 155 160 | 127 132 137 | 15.5 15.5 15.5 | 16 16 16 | SPGW150*127*15.5 SPGW155*132*15.5 SPGW160*137*15.5 |

165 170 180 | 142 147 157 | 15.5 15.5 15.5 | 16 16 16 | SPGW165*142*15.5 SPGW170*147*15.5 SPGW180*157*15.5 |

185 190 200 | 162 167 177 | 15.5 15.5 15.5 | 16 16 16 | SPGW185*162*15.5 SPGW190*167*15.5 SPGW200*177*15.5 |

210 220 225 | 187 197 202 | 15.5 15.5 17 | 16 16 17.5 | SPGW210*187*15.5 SPGW220*197*15.5 SPGW225*202*15.5 |

230 240 250 | 207 217 222 | 17 17 17 | 17.5 17.5 17.5 | SPGW230*207*15.5 SPGW240*217*15.5 SPGW250*222*17 |

260 270 280 | 232 242 252 | 17 17 17 | 17.5 17.5 17.5 | SPGW260*232*17 SPGW270*242*17 SPGW280*252*17 |

300 320 350 | 272 292 322 | 17 17 17 | 17.5 17.5 17.5 | SPGW300*272*17 SPGW320*292*17 SPGW350*322*17 |

Company Features

1. Being one of the leaders in the domestic market, Dms Seals Technology Co.,limited is known for excellence in manufacturing quality . Based in China, Dms Seals Technology Co.,limited is a famous manufacturing company specializing in design, development, manufacturing, sales, and distribution of . Professionalism has made Dms Seals Technology Co.,limited well-known. We have gained good market reputation from customers relying on quality .

2. Dms Seals Technology Co.,limited has a production base, specializing in the production of hydraulic u seal . With accumulated experience in technology, Dms Seals Technology Co.,limited has reached technological standards of the industry. Dms Seals Technology Co.,limited has successfully developed the most technology to use in producing hydraulic rod wipers . Our high quality hydraulic sealing solutions makes our DMS Seal Manufacturer more promising with reasonable price. With outstanding advantage in technology, Dms Seals Technology Co.,limited's buffer seal hydraulic is in sufficient and stable supply.

3. We believe that clear communication and a can-do attitude are the cornerstones of a good supplier-client relationship. And we keep well in our daily business. We are mission-minded. We will always act truthfully and honorably to protect our environment throughout all business practices, such as reducing resource wastes and cutting emissions. We regard customer satisfaction as a core part of our business. We aim to exceed our customers' expectations while meeting their needs and providing professional services. Our core is customer-centric. We will unwaveringly put clients as the top priority, for example, we will do thorough market research before developing or manufacturing products to targeted clients.

Top hydraulic u seal for business for sale

hydraulic u seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US