DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Top double acting seal for pneumatic equipment

1. The machines used for DMS Seal Manufacturer is regularly maintained and upgraded. DMS o-ring seal has advanced machines and equipment for its production

2. Dms Seals Technology Co.,limited has won the trust of its partners in double acting seal industry. We have developed solutions of the sealing of special working condition

3. This product is durable enough. It materials used are new types with high performance and can withstand high-frequency use in the medical environment. To reduce costs with high-efficiency work is the DMS's purpose

4. The product features pressure-crack resistance. It is able to withstand heavy weight load or any exterior pressure without causing any deformation. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

5. The product is easy to operate. Its control system adopts Siemens PLC and touch screen, which is highly automatic and convenient. We can support OEM and ODM

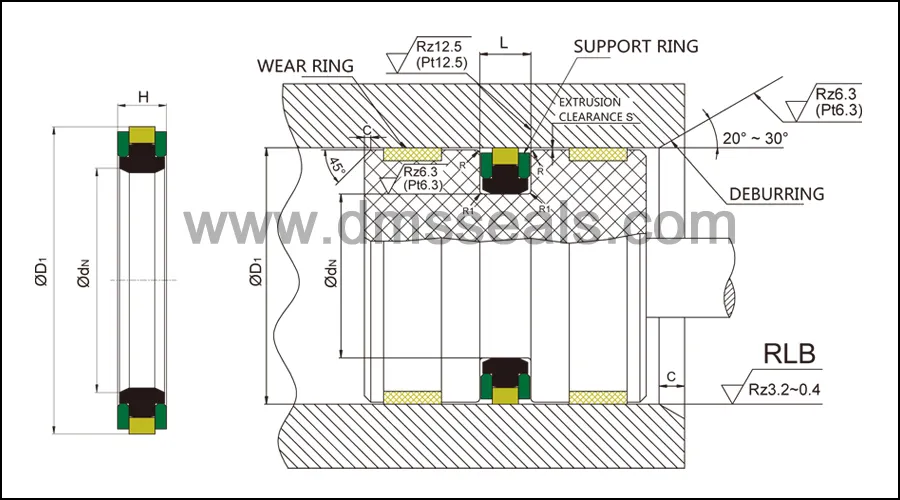

1. Installation Recommendation

2. Application and properties

Suitable for long stroke, a wide range of fluids and high temperature occasions. The application of heavy duty double acting piston sealing under high pressure conditions is excellent. Applicable to larger piston clearance , it has good leakage control, extrusion resistance and wear resistance in heavy duty and construction machinery cylinder piston sealing system. Good static sealing property, simple groove structure, larger extrusion clearances can be allowed, be able to work in dusty condition.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

50 - 350mm | 0 - 50MPa | -30℃ +100℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

Nominal Size of Packing, and Housing dimensions | L+0.2 | Order No. | ||

D1 | dN | H | ||

50 55 60 | 36 41 46 | 8.5 8.5 8.5 | 9 9 9 | SPGW50*36*8.5 SPGW55*41*8.5 SPGW60*46*8.5 |

63 65 70 | 48 50 55 | 10.5 10.5 10.5 | 11 11 11 | SPGW63*48*10.5 SPGW65*50*10.5 SPGW70*55*10.5 |

75 80 85 | 60 65 70 | 10.5 10.5 10.5 | 11 11 11 | SPGW75*60*10.5 SPGW80*65*10.5 SPGW85*70*10.5 |

90 95 100 | 75 80 85 | 10.5 10.5 12 | 11 11 12.5 | SPGW90*75*10.5 SPGW95*80*10.5 SPGW100*85*12 |

105 110 115 | 90 95 100 | 12 12 12 | 12.5 12.5 12.5 | SPGW105*90*12 SPGW110*95*12 SPGW115*100*12 |

120 125 130 | 105 102 107 | 12 15.5 15.5 | 12.5 16 16 | SPGW120*105*12 SPGW125*102*15.5 SPGW130*107*15.5 |

135 140 145 | 112 117 122 | 15.5 15.5 15.5 | 16 16 16 | SPGW135*112*15.5 SPGW140*117*15.5 SPGW145*122*15.5 |

150 155 160 | 127 132 137 | 15.5 15.5 15.5 | 16 16 16 | SPGW150*127*15.5 SPGW155*132*15.5 SPGW160*137*15.5 |

165 170 180 | 142 147 157 | 15.5 15.5 15.5 | 16 16 16 | SPGW165*142*15.5 SPGW170*147*15.5 SPGW180*157*15.5 |

185 190 200 | 162 167 177 | 15.5 15.5 15.5 | 16 16 16 | SPGW185*162*15.5 SPGW190*167*15.5 SPGW200*177*15.5 |

210 220 225 | 187 197 202 | 15.5 15.5 17 | 16 16 17.5 | SPGW210*187*15.5 SPGW220*197*15.5 SPGW225*202*15.5 |

230 240 250 | 207 217 222 | 17 17 17 | 17.5 17.5 17.5 | SPGW230*207*15.5 SPGW240*217*15.5 SPGW250*222*17 |

260 270 280 | 232 242 252 | 17 17 17 | 17.5 17.5 17.5 | SPGW260*232*17 SPGW270*242*17 SPGW280*252*17 |

300 320 350 | 272 292 322 | 17 17 17 | 17.5 17.5 17.5 | SPGW300*272*17 SPGW320*292*17 SPGW350*322*17 |

Company Features

1. Abundant technical skills, advanced technology and excellent equipment ensure the quality of Dms Seals Technology Co.,limited's products.

2. Being committed to double acting seal makes DMS Seal Manufacturer more famous in this field. Get an offer!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US