DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

spring spring seals seals single acting seal DMS Seal Manufacturer

-

v s

1. The production of DMS Seal Manufacturer spring energized seals adopts internationally recognized standards.

2. The product has reliable performance in even the most demanding applications.

3. Every manufacturing process is well institutionalized and equipped with highly precise testing instruments to control the production and product quality.

4. Dms Seals Technology Co.,limited has strong growth, upgrade and optimization capabilities.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

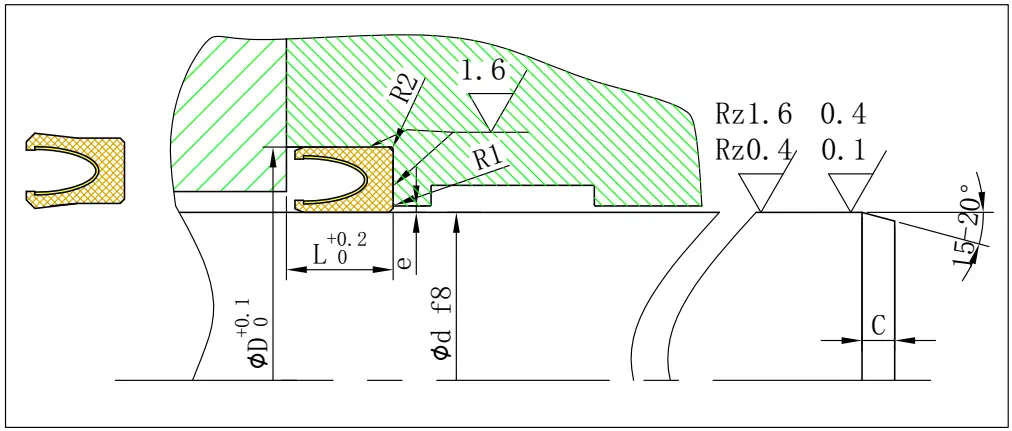

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is a leading manufacturer with highly advanced technology and maturely design crafts.

2. Dms Seals Technology Co.,limited achieves R&D progresses annually.

3. Dms Seals Technology Co.,limited adheres to the service philosophy of spring energized seals . Check now! The service concept of spring loaded seal has been established in Dms Seals Technology Co.,limited. Check now! oil seal spring is Dms Seals Technology Co.,limited original service idea, which fully shows its own superiority. Check now!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US