DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

rod seal glyd ring for piston and hydraulic cylinder DMS Seal Manufacturer

- Dms Seals runs the business in good faith and puts customers in the first. We are dedicated to providing quality services for customers.

1. The design style of DMS Seal Manufacturer piston rings by bore size can be varied according to different requirements.

2. The production of DMS Seal Manufacturer rod seal adopts advanced technology and latest machines & equipment.

3. Made of premium quality materials, DMS Seal Manufacturer piston rings by bore size is manufactured as per the norms of the industry.

4. The product is unmatched in performance, service life and usability.

5. Compared with other products, this product has obvious advantages, longer service life and more stable performance. It has been tested by an authoritative third party.

6. The product has been certified to a number of recognized standards, such as ISO quality standards.

7. We put quality first to ensure reliable product quality.

8. The product is highly reliable in performance and it is of relatively long service life.

9. This product can bring huge benefits for business owners, such as its incredible safety. It can ensure a decrease in work accidents.

10. The product directly contributes to improving productivity. Because it can work much faster than human and reduce errors, saving time for production.

11. This product will finally contribute to the improvement in production efficiency. Because it can effectively eliminate human error during operation.

12. The product is easy for people to control and only needs a little workforce. This will help lower operating costs.

13. This product can help people finish tasks that are too heavy or difficult. It significantly reduces the work burden for people.

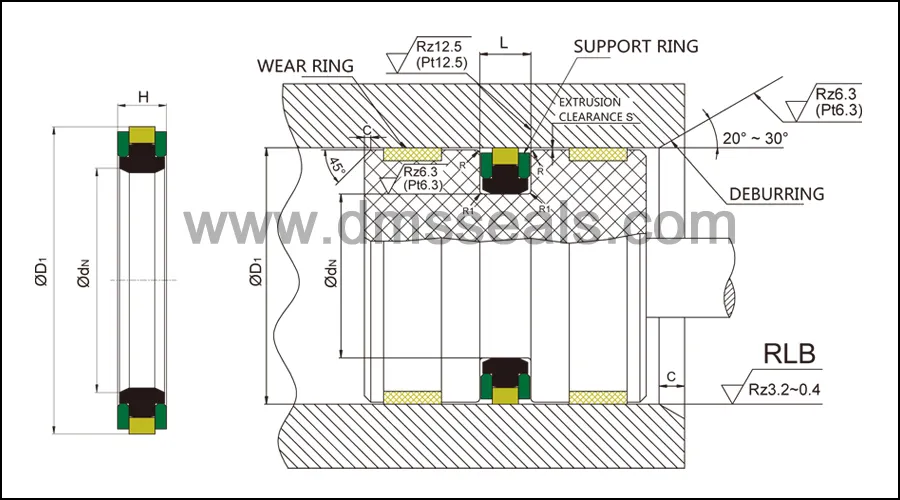

1. Installation Recommendation

2. Application and properties

Suitable for long stroke, a wide range of fluids and high temperature occasions. The application of heavy duty double acting piston sealing under high pressure conditions is excellent. Applicable to larger piston clearance , it has good leakage control, extrusion resistance and wear resistance in heavy duty and construction machinery cylinder piston sealing system. Good static sealing property, simple groove structure, larger extrusion clearances can be allowed, be able to work in dusty condition.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

50 - 350mm | 0 - 50MPa | -30℃ +100℃ | 1.5 m/s | hydraulic oil, flame retardant liquid, water and others |

5. Installation Dimensions

Nominal Size of Packing, and Housing dimensions | L+0.2 | Order No. | ||

D1 | dN | H | ||

50 55 60 | 36 41 46 | 8.5 8.5 8.5 | 9 9 9 | SPGW50*36*8.5 SPGW55*41*8.5 SPGW60*46*8.5 |

63 65 70 | 48 50 55 | 10.5 10.5 10.5 | 11 11 11 | SPGW63*48*10.5 SPGW65*50*10.5 SPGW70*55*10.5 |

75 80 85 | 60 65 70 | 10.5 10.5 10.5 | 11 11 11 | SPGW75*60*10.5 SPGW80*65*10.5 SPGW85*70*10.5 |

90 95 100 | 75 80 85 | 10.5 10.5 12 | 11 11 12.5 | SPGW90*75*10.5 SPGW95*80*10.5 SPGW100*85*12 |

105 110 115 | 90 95 100 | 12 12 12 | 12.5 12.5 12.5 | SPGW105*90*12 SPGW110*95*12 SPGW115*100*12 |

120 125 130 | 105 102 107 | 12 15.5 15.5 | 12.5 16 16 | SPGW120*105*12 SPGW125*102*15.5 SPGW130*107*15.5 |

135 140 145 | 112 117 122 | 15.5 15.5 15.5 | 16 16 16 | SPGW135*112*15.5 SPGW140*117*15.5 SPGW145*122*15.5 |

150 155 160 | 127 132 137 | 15.5 15.5 15.5 | 16 16 16 | SPGW150*127*15.5 SPGW155*132*15.5 SPGW160*137*15.5 |

165 170 180 | 142 147 157 | 15.5 15.5 15.5 | 16 16 16 | SPGW165*142*15.5 SPGW170*147*15.5 SPGW180*157*15.5 |

185 190 200 | 162 167 177 | 15.5 15.5 15.5 | 16 16 16 | SPGW185*162*15.5 SPGW190*167*15.5 SPGW200*177*15.5 |

210 220 225 | 187 197 202 | 15.5 15.5 17 | 16 16 17.5 | SPGW210*187*15.5 SPGW220*197*15.5 SPGW225*202*15.5 |

230 240 250 | 207 217 222 | 17 17 17 | 17.5 17.5 17.5 | SPGW230*207*15.5 SPGW240*217*15.5 SPGW250*222*17 |

260 270 280 | 232 242 252 | 17 17 17 | 17.5 17.5 17.5 | SPGW260*232*17 SPGW270*242*17 SPGW280*252*17 |

300 320 350 | 272 292 322 | 17 17 17 | 17.5 17.5 17.5 | SPGW300*272*17 SPGW320*292*17 SPGW350*322*17 |

Company Features

1. Dms Seals Technology Co.,limited has long been committed to the R&D and production of rod seal . DMS Seal Manufacturer manufactures and markets a diverse range of hydraulic rod seals as a leading supplier. DMS Seal Manufacturer is a famous brand that specializes in producing glyd ring for years. DMS Seal Manufacturer now leads the trend of hydraulic cylinder piston seals industry. After years of stable development, Dms Seals Technology Co.,limited has become one of leading piston seals manufacturers.

2. Up to now, the factory has been equipped with multi manufacturing facilities, as well as necessary testing equipment. All of which are executed by following the ISO 9001 management system. Our team of professionals has extensive experience and knowledge. They place great emphasis on providing quality workmanship and quick turn around times for our customers. We have a skillful management team. They can find the biggest challenges for manufacturing including generating sales at good margins and ensuring productivity from automation. Our factory has advanced manufacturing machines. The use of these machines means that all major operations are automated or semi-automated and that increases the speed and quality of products.

3. Under the guidance of DMS Seal Manufacturer’s view of piston rings by bore size, we more firmly implement the development strategy for the benefits of company. Get more info! Dms Seals Technology Co.,limited aims to provide customers with high-performance, professional and agile services. Get more info! The corporate vision of Dms Seals Technology Co.,limited is committed to building a world-class rod seal company with core competitiveness! Get more info! Dms Seals Technology Co.,limited aims to help customers throughout the service process to obtain the maximum satisfaction. Get more info!

rod seal glyd ring for piston and hydraulic cylinder DMS Seal Manufacturer

rod seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US