DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

Quality DMS Seal Manufacturer Brand seal spring spring energized seals

- Dms Seals's production team is equipped with rich theoretical and practical know-how in the industry. This allows them to find out and improve the problems occurred during the production in time. All this guarantees the best quality of products.

- Dms Seals puts the customer first and provides them with quality services.

- Based on sincerity-based management, Dms Seals intends to be aspirant and positive to create mutual benefit. We also comply with the core value of 'customer-centered, technology-led, innovation-driven'. In order to better play synergistic effect, we keep ourselves open to partnerships with excellent enterprises in the industry and complement with each other by advantages. All these improve the corporate brand's influence and promote healthy and sustainable development.

- Since the establishment in 2006, Dms Seals has been committed to providing high-quality O-ring Seal for customers. Now we are on the way of becoming a leader in the industry.

- Dms Seals's products are sold well at home and abroad.

1. Manufactured using supreme quality raw material and the most advanced techniques, DMS Seal Manufacturer spring energized seals shows fine craftsmanship. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

2. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians Simultaneously, the use of spring loaded seal concept can make spring energized seals more oil seal spring.

3. With many good characteristics, the product successfully wins the high level of customer's satisfaction, which implies its promising market potential. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

4. Since the product meets the customer's expectation perfectly, the product will have a wider market. DMS o-ring seal has advanced machines and equipment for its production

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

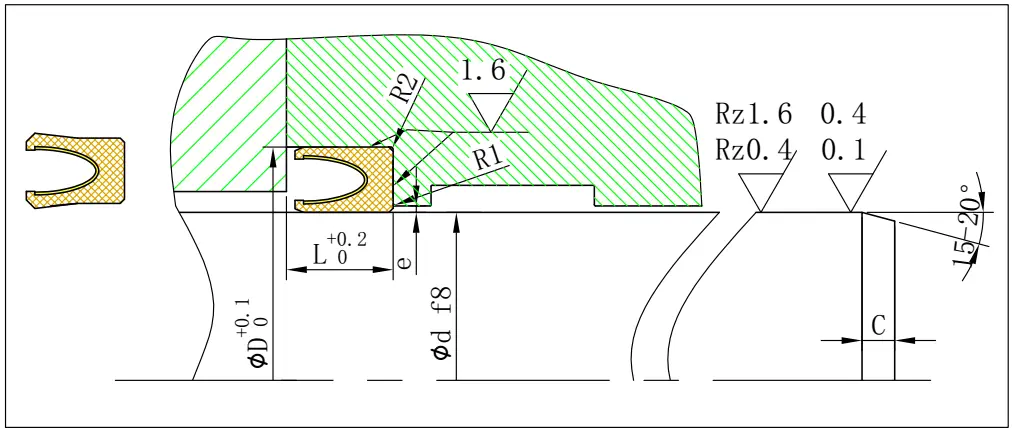

4. Installation Sizes

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited puts great energy on R&D and production of spring energized seals.

2. DMS Seal Manufacturer is capable of producing high-quality spring seals.

3. The work on intensifying the service idea of spring energized seals has never been stopped by Dms Seals Technology Co.,limited. Call now!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US