DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

ptfe spring energized seals parts for reciprocating piston rod or piston single acting seal

- Dms Seals has established a brand-new service concept to offer more, better, and more professional services to customers.

1. The creation of DMS Seal Manufacturer spring energized seals involves some advanced technologies. They include mechanical systems technology, automatic control technology, sensing technology, and servo-drive technology.

2. DMS Seal Manufacturer spring energized seals has gone through some important production stages. They cover the preparation of raw materials, parts machining, plating and anodizing, assembly, and testing.

3. DMS Seal Manufacturer spring energized seals has been tested according to the general standards. It is tested in terms of functionality, strength, stiffness, wears, and corrosion.

4. The modern metallic finish offers beauty and luster. Its surface has been finely polished and washed during the finished product stage.

5. This product feature delicate workmanship. Its paint is finely done with automatic painting machine, and its parquets are all hand-made with good details.

6. The product has excellent strength and hardness. Constructed of heavy-duty welded metal, its structure is too tough to be deformed.

7. The product is able to protect the foot against hurt. It is designed based on the ergonomics which distributes the negative pressure evenly and provides support to the foot.

8. The product has received great trust and high praise from the vast of customers, showing a great market potential.

9. The product has become the focus of the industry and embraces a bright application prospect.

10. The product, with the rising popularity and reputation, wins a larger market share.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

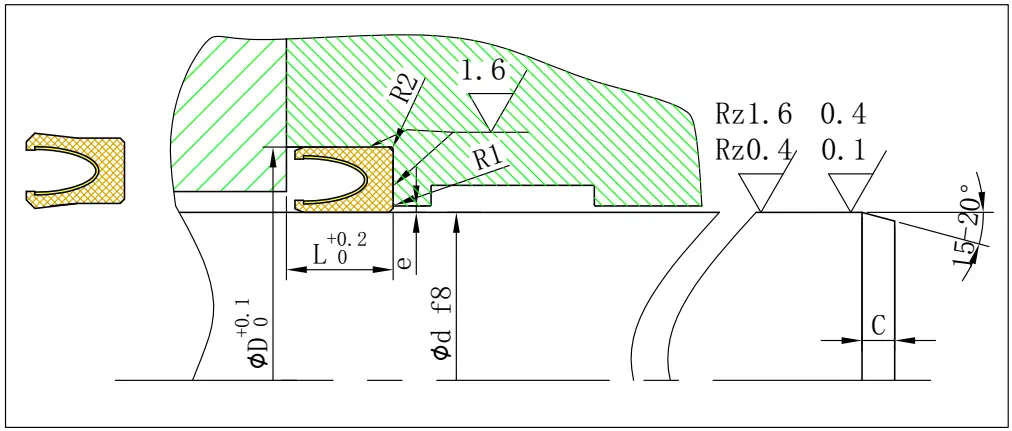

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Equipped with the most advanced machines, Dms Seals Technology Co.,limited is a professional manufacturer for spring energized seals . Dms Seals Technology Co.,limited has accumulated a good reputation and image in spring seals market. oil seal manufacturer is concentrated on the spring energized seals which helps customers to solve problems.

2. The factory has established an excellent quality management system that covers several subsystems, such as production systematization, process standardization, and resource management. This system gives us more flexibility and better control over the whole production. Our factory is well-equipped. We continue to invest heavily in the latest equipment such as high-speed equipment, to ensure satisfying quality, capacity, time-to-market, and costs. We have a creative design team. With their innovation and motivation, they are able to design innovative products in compliance with the latest modern trends and styles.

3. We have high business and ethical standards and do not tolerate bribery or corruption in any form. To support this, we've developed a Statement of Business and Ethics Code which sets out the guiding principles by which we all operate. We will continue to follow the tenet of 'providing quality products for customers'. Contact! Our team at DMS Seal Manufacturer provides the best support and products to our customers. Contact! The main current objective of our company is to increase customer satisfaction. We are cultivating a professional team to provide quality products and service for clients. We believe that higher customer satisfaction brings higher profits. Contact! Dms Seals Technology Co.,limited is willing to provide customers with customized spring energized seals . Contact!

ptfe spring energized seals parts for reciprocating piston rod or piston single acting seal

spring energized seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US