DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

ptfe rotary seals manufacturer online for automotive equipment

1. With the assistance of skilled professionals, the production of DMS Seal Manufacturer rotary seals manufacturer is carried out according to the principles of lean production. DMS Seals provides professional design and production of high-grade o-ring seals

2. Dms Seals Technology Co.,limited grantees every rotary seals manufacturer we offered is a quality rotary shaft seals . Seal we produced has applications in a wide range of fields

3. It is not known that rotary shaft seals from Dms Seals Technology Co.,limited have exceeded the performance and quality of many big names. DMS Seals' production equipment and test equipment are on the leading level in the industry

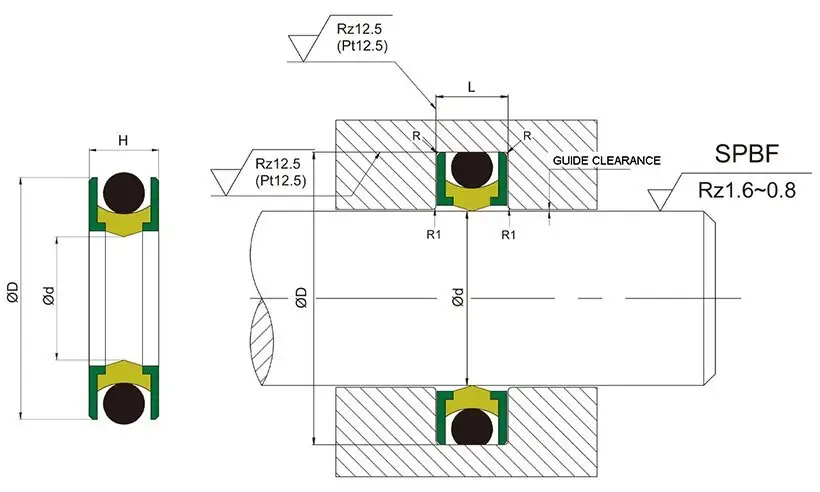

Rod Diameter | Groove Diameter | Seal Width | Groove Width | Guide Clearance S max | |

d e8 | D H9 | H | L | 0-10MPa | 15-36MPa |

50-79 | d+10.0 | 4.5 | 5.0 | 0.40-0.30 | 0.30-0.25 |

80-109 | d+13.8 | 7.0 | 7.5 | 0.45-0.35 | 0.35-0.30 |

110-299 | d+20.0 | 9.5 | 10.0 | 0.55-0.45 | 0.45-0.35 |

300-600 | d+24.0 | 12.5 | 13.0 | 0.60-0.55 | 0.55-0.45 |

Application and properties

Applicable to construction machinery, construction machinery and automotive equipment and other industrial fields. Consisting of a sealing ring, a O-Ring and two retaining rings, the sealing surface profile is specially designed to accommodate high pressure and low speed, the design of the back of the seal ring increases the contact surface and prevents rotation with the rod or shaft. Low friction, non viscous phenomenon, simple groove, good abrasion resistance and dimensional stability.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-36MPa | -36℃+100℃ | 0.5 m/s | hydraulic oil, flame retardant liquid, water and others |

d e8 | D H9 | H | L | e | Order No. |

50 | 60 | 4.5 | 5 | 7 | OI50*60*4.5 |

65 | 75 | 4.5 | 5 | 7 | OI65*75*4.5 |

80 | 93.8 | 7.0 | 7.5 | 7 | OI80*93.8*7 |

95 | 108.8 | 7.0 | 7.5 | 7 | OI95*108.8*7 |

115 | 135 | 9.5 | 10 | 10 | OI115*135*9.5 |

130 | 150 | 9.5 | 10 | 10 | OI130*150*9.5 |

160 | 180 | 9.5 | 10 | 10 | OI160*180*9.5 |

190 | 210 | 9.5 | 10 | 10 | OI190*210*9.5 |

225 | 245 | 9.5 | 10 | 10 | OI225*245*9.5 |

Company Features

1. Dms Seals Technology Co.,limited has been regarded as a renowned company in China. We are engaged in market research, designing, manufacturing of rotary seals manufacturer .

2. DMS Seal Manufacturer has introduced advanced technical methods to guarantee the quality of rotary shaft seals .

3. Dms Seals Technology Co.,limited will continue to strengthen technological innovation to enhance the overall competitive advantage in the international rotary seals industry. Inquiry!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US