DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

ptfe piston seals with ptfe nbr and pom for pneumatic equipment

- Dms Seals can provide high-quality and efficient management consulting service for customers at any time.

1. The inspections for DMS Seal Manufacturer hydraulic piston seals are conducted based on quality control procedures. These procedures include fabrics, checking, size measurement, sewing, and finishing.

2. DMS Seal Manufacturer hydraulic piston seals has to go through a wide range of production stages. These stages cover research based on feet shape, CAD design, material cutting, stamping, sewing, and stitching, and assembly.

3. DMS Seal Manufacturer hydraulic piston seals has been 100% tested in terms of many aspects. They mainly are care labeling, colorfastness, fabric construction, dimensional stability, etc.

4. Its surface is endowed with a metallic gloss. The product is treated with an electroplating technique to create a metallic membrane on its surface.

5. The product features a long service life. The light-emitting element adopts a high-composite material to minimize the aging effect that caused by long-time high-temperature working.

6. The product has superior thermodynamic property. Its rational structure helps it make full use of the heat exchange capacity of the condenser.

7. The product features excellent color fastness. There are no excessive dyes being deposited on the fabric surface to affect the firmness of the fabric's colorfastness.

8. The product is going to expand market further as we keep product improvement.

9. The reputation and competitiveness of this range has raised apparently in recent years.

10. With the widespread reputation, the product will be applied more in the future.

Application and properties

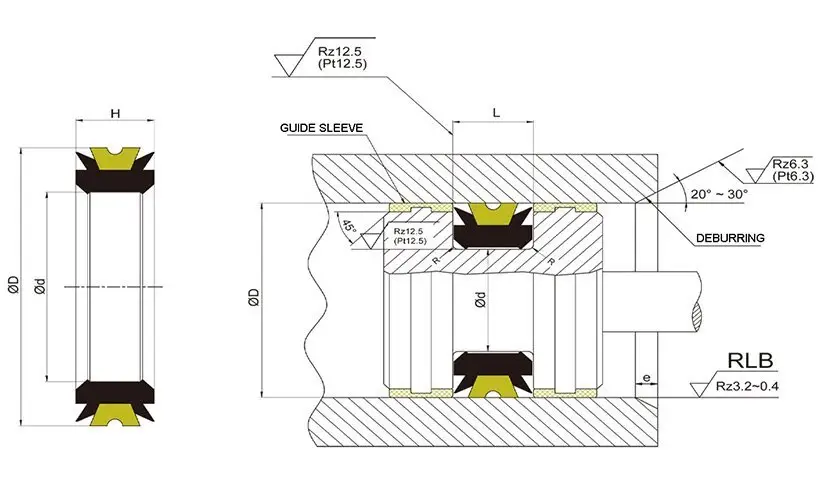

Suitable for seals of pistons and plungers, tandem seals for a variety of liquid applications are internal seals. Before installation, the sealing lip is protruded outwards, and the cylinder liner is pressed tightly after installation to provide elasticity for the wear ring, excellent sealing results can be achieved even in the absence of pressure. It can separate the liquid on both sides of the sealing ring, so it is also suitable for the sealing of the oil chamber, and the invasion of other liquids can be prevented. High wear resistance, low friction, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

Elastomer: NBR / PU

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-25MPa | -30℃+100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L+0.2 | e | Order No. |

40 | 30 | 15 | 16 | 7 | DDMA40*30*16 |

56 | 46 | 15 | 16 | 7 | DDMA56*46*16 |

70 | 60 | 15 | 16 | 7 | DDMA70*60*16 |

85 | 75 | 15 | 16 | 7 | DDMA85*75*16 |

100 | 90 | 15 | 16 | 7 | DDMA100*90*16 |

120 | 110 | 15 | 16 | 7 | DDMA120*110*16 |

135 | 123 | 15 | 16 | 10 | DDMA135*123*16 |

150 | 138 | 15 | 16 | 10 | DDMA150*138*16 |

170 | 158 | 15 | 16 | 10 | DDMA170*158*16 |

200 | 188 | 15 | 16 | 10 | DDMA200*188*16 |

225 | 213 | 15 | 16 | 10 | DDMA225*213*16 |

Company Features

1. As a piston seals supplier, DMS Seal Manufacturer has been committed to improving quality and professional services. As a large company, Dms Seals Technology Co.,limited mainly focuses on hydraulic piston seals . Dms Seals Technology Co.,limited is a company specializing in o-ring seal and related product development, design and production. As a large manufacturer of piston seals , Dms Seals Technology Co.,limited have a wide range of overseas markets.

2. Dms Seals Technology Co.,limited has influential technical approaches to improve the quality of piston seals . By keeping innovating the piston seals technology, we can stay in the advancing front of the technology. piston seals is made from the revolutionary technology.

3. That profession creates excellence is the belief DMS Seal Manufacturer holds. Get more info! hydraulic piston seals is the core of the Dms Seals Technology Co.,limited's business and the foundation for the its development. Get more info! DMS Seal Manufactureralways improves the leading expertise and consistently delivers high-quality piston seals . Get more info! In decades of years of development, Dms Seals Technology Co.,limited has established a set of scientific guidelines for the management of factories. Get more info!

ptfe piston seals with ptfe nbr and pom for pneumatic equipment

piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US