DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

ptfe hydraulic DMS Seal Manufacturer Brand hydraulic rod seals

1. The high pressure seals have strong wear resistance to hard conditions. Presented products are enormously appreciated by DMS Seal Manufacturer customers for characteristics such as hydraulic rod seals and piston rod seal.

2. DMS o-ring seal has advanced machines and equipment for its production. DMS Seal Manufacturer – a famous brand of rod seals,hydraulic rod seals online, proudly designs and produces hydraulic rod seals,rod seal catalogue.

3. Our products mainly include rod seals, piston seals, scraper seals, rotary seals, rubber seal products and spring seals. With the unique O Ring Manufacturers,pneumatic rod seals,our product is better with it.

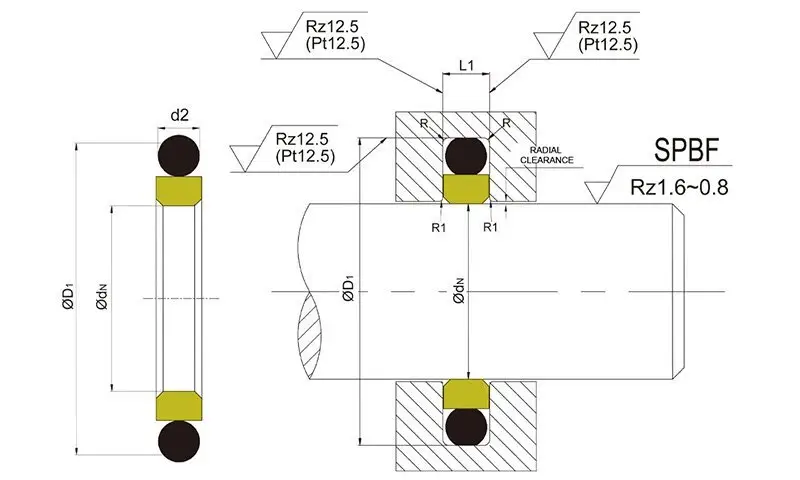

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | colspan="3"> Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in the medium with oil spots. Meet the standard of GB/T 15242.3.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

4 | 8.9 | 2.2 | GSI4*8.9*2.2 | 5.6*1.8 |

8 | 12.9 | 2.2 | GSI8*12.9*2.2 | 9.5*1.8 |

10 | 17.3 | 3.2 | GSI10*17.3*3.2 | 12.37*2.62 |

14 | 18.9 | 2.2 | GSI14*18.9*2.2 | 15.6*1.78 |

15 | 22.3 | 3.2 | GSI15*22.3*3.2 | 17.12*2.62 |

18 | 22.9 | 2.2 | GSI18*22.9*2.2 | 20.35*1.78 |

20 | 27.3 | 3.2 | GSI20*27.3*3.2 | 21.89*2.62 |

22 | 32.7 | 4.2 | GSI22*32.7*4.2 | 26.57*3.53 |

25 | 35.7 | 4.2 | GSI25*35.7*4.2 | |

28 | 38.7 | 4.2 | GSI28*38.7*4.2 | 32.92*3.53 |

32 | 39.3 | 3.2 | GSI32*39.3*3.2 | 34.59*2.62 |

35 | 45.7 | 4.2 | GSI35*45.7*4.2 | 37.69*3.53 |

38 | 48.7 | 4.2 | GSI38*48.7*4.2 | 40.87*3.53 |

40 | 55.1 | 6.3 | GSI40*55.1*6.3 | 43.82*5.33 |

45 | 55.7 | 4.2 | GSI45*55.7*4.2 | 50.39*3.53 |

48 | 63.1 | 6.3 | GSI48*63.1*6.3 | 53.34*5.33 |

52 | 62.7 | 4.2 | GSI52*62.7*4.2 | 56.74*3.53 |

55 | 65.7 | 4.2 | GSI55*65.7*4.2 | 59.92*3.53 |

56 | 71.1 | 6.3 | GSI56*71.1*6.3 | 62.87*5.33 |

60 | 75.1 | 6.3 | GSI60*75.1*6.3 | 66.04*5.33 |

65 | 80.1 | 6.3 | GSI65*80.1*6.3 | 69.22*5.33 |

70 | 85.1 | 6.3 | GSI70*85.1*6.3 | 75.57*5.33 |

75 | 90.1 | 6.3 | GSI75*90.1*6.3 | 81.92*5.33 |

83 | 93.7 | 4.2 | GSI83*93.7*4.2 | 88.49*3.53 |

90 | 100.7 | 4.2 | GSI90*100.7*4.2 | 94.84*3.53 |

95 | 105.7 | 4.2 | GSI95*105.7*4.2 | 101.19*3.53 |

100 | 115.1 | 6.3 | GSI100*115.1*6.3 | 107.32*5.33 |

Company Features

1. DMS Seal Manufacturer is quality-oriented and has gained wide market in rod seals field. - At present, Dms Seals Technology Co.,limited has advanced production lines and various testing equipment for hydraulic rod seals.

2. Over hundreds of skilled O Ring Manufacturers technicians provide customers with the most sophisticated products.

3. DMS Seal Manufacturer has been always stressing the importance of o-ring seal . - Ensuring a harmonious environment between employees can provide the best rod seals. Call now!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US