DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

ptfe bearing element wear ring for sale

- Dms Seals attaches great importance to the impact of service on corporate reputation. We are dedicated to providing professional and high-quality services for customers.

1. DMS Seal Manufacturer rubber seal design is strictly inspected. Not only does it have gone through a machine check on cutting, welding, and surface treatment, but also is inspected by workers.

2. The electrolytes of DMS Seal Manufacturer bearing element are well treated to have high ionic conductivity and good wetting characteristics, particularly for high power applications.

3. DMS Seal Manufacturer rubber seal design is processed to meet the new concept of 'green buildings'. Some of its raw materials are obtained from the recycled materials and the waste discharge are totally eliminated.

4. This product is able to maintain its original structure. It has the ability to resist fracture or breakdown when withstanding heaving loading.

5. The product is strongly resistant to get rusty. It has an oxide protective layer which allows it to stand up the damage of wet environments.

6. The product is less likely to accumulate the bacteria. The materials used features strong antibacterial property which can effectively reduce the growth of bacteria.

7. This product has great strength. Its parts are able to withstand various stresses caused by the load, such as thermal stresses, torsional stresses, and bending stress.

8. DMS Seal Manufacturer has been very popular for its good quality assurance.

9. Before delivery, bearing element will conduct several rounds of strict tests for quality.

10. DMS Seal Manufacturer has established a strict quality guarantee system to guarantee the quality of bearing element .

11. Thanks to the quality assurance of bearing element , our sales network has been reaching out in all directions.

12. Dms Seals Technology Co.,limited gives technical assurance and first-class quality.

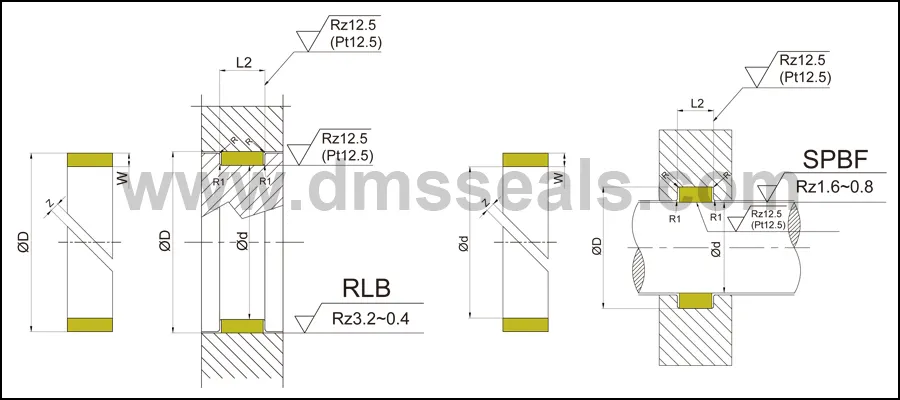

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

White virgin PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited is a bearing element company with greater strength in the industry. DMS Seal Manufacturer is developing into a leading oil seal manufacturer maker. The advantage of large scaled factory helps Dms Seals Technology Co.,limited consolidate the status in the bearing element market. Dms Seals Technology Co.,limited provides high quality bearing element with stable performance. Dms Seals Technology Co.,limited has been focusing on the production of high-quality bearing element since inception.

2. It is our high quality that makes bearing element dominates most part of markets. Being qualified with the authoritative certifications, we are more confident to produce bearing element with rubber seal design . Dms Seals Technology Co.,limited has a production base of thousands of square meters and hundreds of production employees. Dms Seals Technology Co.,limited attaches great importance to the research and development of new and international bearing element products. rubber seal ring manufacturers are special for bearing element to be used at any situation.

3. We adhere to the principle of 'build a reputation via innovation'. We will continue to invest in talents development and R&D. Ask! Doing well is the common pursuit and ideal of DMS Seal Manufacturer. Ask! The goal of Dms Seals Technology Co.,limited is to introduce rubber seal manufacturers into the international market. Our success is enabled by the commitment and dedication of our employees globally. With our focus on a progressive, diverse and inclusive culture, growth through innovation in emerging markets and services and operational excellence. Ask!

ptfe bearing element wear ring for sale

bearing element

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US