DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

pneumatic rod seals for pressure work and sliding high speed occasions DMS Seal Manufacturer

1. DMS Seal Manufacturer pneumatic rod seals must go through these following production stages, including metal materials procurement and preparation, components machining, surface polishing, and assembly. Quality control of the seals is the basis for DMS Seals

2. This product can be used for a long time. Customers who often use it to hold food for three years praised that it still looks like the brand new one. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

3. The product is not easy to fracture. It has a strong performance in resisting extreme cold and extreme high temperature. To reduce costs with high-efficiency work is the DMS's purpose

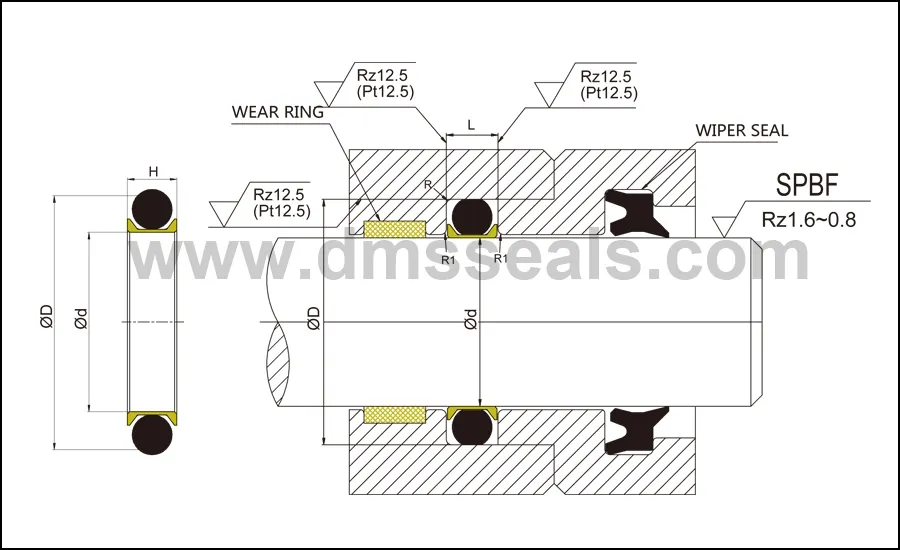

1. Installation Recommendation

2. Application and properties

The standard combination seal is suitable for a wide range of pressure work and sliding high speed occasions. Low friction, strong wear resistance.

3. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 35MPa | -30℃ +200℃ | 1.5 m/s | general hydraulic oil, water glycol Hydraulic oil and water emulsion type hydraulic oil. |

5. Installation Dimensions

Order No. | ||||

d | D | H | L +0.2 | |

3 4 5 | 6 7 8 | 2.3 2.3 2.3 | 2.5 2.5 2.5 | SPNC3*6*2.5 SPNC4*7*2.5 SPNC5*8*2.5 |

6 7 8 | 9 10 11 | 2.3 2.3 2.3 | 2.5 2.5 2.5 | SPNC6*9*2.5 SPNC7*10*2.5 SPNC8*11*2.5 |

9 10 10 | 12 13 14 | 2.3 2.3 3.0 | 2.5 2.5 3.2 | SPNC9*12*2.5 SPNC10*13*2.5 SPNC10*14*3.2 |

11 11.2 12 | 15 15.2 16 | 3.0 3.0 3.0 | 3.2 3.2 3.2 | SPNC11*15*3.2 SPNC11.2*15.2*3.2 SPNC12*16*3.2 |

12.5 14 15 | 16.5 18 19 | 3.0 3.0 3.0 | 3.2 3.2 3.2 | SPNC12.5*16.5*3.2 SPNC14*18*3.2 SPNC15*19*3.2 |

16 18 20 | 20 22 24 | 3.0 3.0 3.0 | 3.2 3.2 3.2 | SPNC16*20*3.2 SPNC18*22*3.2 SPNC20*24*3.2 |

20 21 22 | 24 25 26 | 3.0 3.0 3.0 | 3.2 3.2 3.2 | SPNC20*24*3.2 SPNC21*25*3.2 SPNC22*26*3.2 |

22 22.4 24 | 28 28.4 30 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC22*28*4.7 SPNC22.4*28.4*4.7 SPNC24*30*4.7 |

25 25.5 26 | 31 31.5 32 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC25*31*4.7 SPNC25.5*31.5*4.7 SPNC26*32*4.7 |

28 29 29.5 | 34 35 35.5 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC28*34*4.7 SPNC29*35*4.7 SPNC29.5*35.5*4.7 |

30 31 31.5 | 36 37 37.5 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC30*36*4.7 SPNC31*37*4.7 SPNC31.5*37.5*4.7 |

32 34 35 | 38 40 41 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC32*38*4.7 SPNC34*40*4.7 SPNC35*41*4.7 |

35.5 36 38 | 41.5 42 44 | 4.4 4.4 4.4 | 4.7 4.7 4.7 | SPNC35.5*41.5*4.7 SPNC36*42*4.7 SPNC38*44*4.7 |

Company Features

1. DMS Seal Manufacturer now is an outstanding rod seals manufacturer. We continue to invest in advanced production facilities to connect our equipment, people and processes. This will finally help us improve productivity, quality, responsiveness, as well as the accuracy of decision making throughout the product lifecycle.

2. We own a complete production house. It executes the strictest quality management control system in the industry. From R&D, design, raw materials selection, production, quality inspection, to product packaging, every stage in under scrutinization by professionals.

3. Our business has expanded across five continents. In turn, we gain unique insights from around the world, integrating best practice and innovative developments to strengthen our competitive advantage. To uphold our commitment to responsible and sustainable development, we have made a long-term plan to reduce our carbon footprint and pollution on the environment.

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US