DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

piston seals for pneumatic equipment DMS Seal Manufacturer

1. DMS Seal Manufacturer hydraulic piston seals has passed the electrical safety testing, including electromagnetic disturbance level testing, surge testing, electrostatic discharge testing, and electric leakage testing.

2. The tests for DMS Seal Manufacturer piston seals have been conducted using state-of-the-art testing machines. These tests include vibration and shock testing, climatic and salt testing, noise and vibration testing, etc.

3. DMS Seal Manufacturer hydraulic piston seals is strictly manufactured according to GB or IEC. Its contactor, rheostat, control relay, and other electronic components are handled based on relevant electric and safety standards.

4. The design of DMS Seal Manufacturer hydraulic piston seals is carefully conducted. Its electric circuit parts are finely arranged after consideration of circuit compatibility.

5. Professional staff strictly check, to ensure that products always maintain the highest quality.

6. This product has unparalleled advantages of other products, such as long life and stable performance.

7. The product has been tested by a third-party authoritative agency, which is a great guarantee on its high quality and stable functionality.

8. The products have passed the overall quality inspection before they leave the factory.

9. The product has achieved a high level of client satisfaction because it is highly cost-effective and is thought to be used more widely in the market.

10. This product is highly appreciated among end users due to its trouble-free performance and superior quality.

11. This product is over and above our rival's product, and yet we're able to sell it at the same price.

12. This product is widely used in the industry and it is deeply trusted by users at home and abroad.

13. We offer this product in a myriad of appealing shades and finishes to suit the theme of different interior.

Application and properties

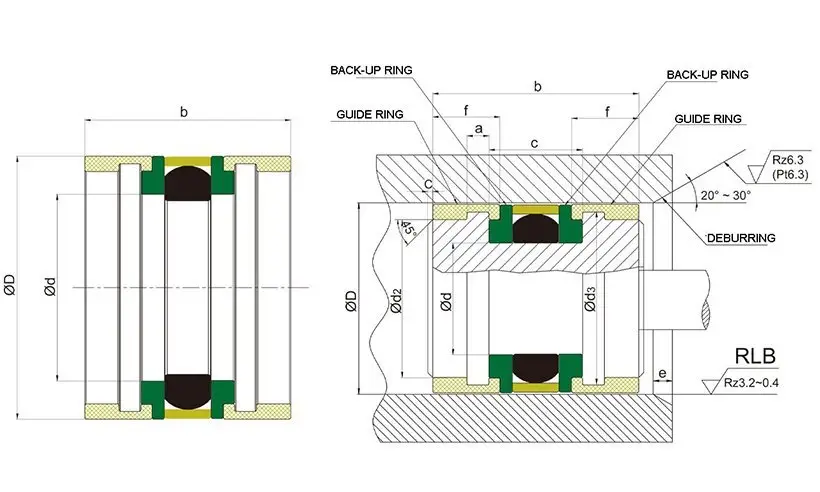

Apply to cylinder piston, consisting of a seal ring, an O-Ring, a pair of retaining rings and a pair of guide sleeves. The seal ring and cylinder bore conforming to be a symmetric section to achieve the sealing performance, with double acting sealing performance.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Back-up ring: filled PTFE / PA

Guide ring: filled PTFE / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+200℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

D | d | b | d2 | d3 | a | c | f | e | Order No. |

40 | 26 | 32 | 32 | 36 | 3.5 | 15.5 | 8.25 | 7 | DDKK40*26*32 |

56 | 40 | 39 | 48 | 52 | 3 | 20.5 | 9.25 | 7 | DDKK56*40*39 |

65 | 49 | 39 | 57 | 61 | 3 | 20.5 | 9.25 | 7 | DDKK65*49*39 |

80 | 62 | 43 | 72 | 76 | 3 | 22.5 | 10.25 | 7 | DDKK80*62*43 |

95 | 77 | 43 | 87 | 91 | 3 | 22.5 | 10.25 | 7 | DDKK95*77*43 |

110 | 92 | 43 | 102 | 106 | 3 | 22.5 | 10.25 | 10 | DDKK110*92*43 |

125 | 103 | 53 | 115 | 121 | 4 | 26.5 | 13.25 | 10 | DDKK125*103*53 |

150 | 128 | 53 | 140 | 146 | 4 | 26.5 | 13.25 | 10 | DDKK150*128*53 |

170 | 148 | 57 | 160 | 166 | 6 | 26.5 | 15.25 | 10 | DDKK170*148*57 |

195 | 170 | 64 | 185 | 191 | 4.5 | 31.5 | 16.25 | 10 | DDKK195*170*64 |

Company Features

1. Dms Seals Technology Co.,limited is a professional company engaged in the R&D, design, and manufacturing of hydraulic piston seals for many years. Dms Seals Technology Co.,limited has a large-scale factory that focuses on the production of piston seals . Through continuous technological innovation, Dms Seals Technology Co.,limited is in a leading position in the o-ring seal industry. The strong R&D, manufacturing, and marketing capability make Dms Seals Technology Co.,limited be a pioneer in the manufacturing of hydraulic piston seals in China. With talented sales team and rich export experience, Dms Seals Technology Co.,limited sells piston seals to many countries.

2. Dms Seals Technology Co.,limited has a strong sense of innovation and marketing model. Dms Seals Technology Co.,limited implements new and advanced technologies to its business processes. Dms Seals Technology Co.,limited is known for the cutting-edge production technology.

3. Needless to say that Dms Seals Technology Co.,limited will provide best service for our customers. Please contact. Dms Seals Technology Co.,limited is determined to build itself into the largest piston seals production base worldwide in the following years. Please contact. The mission of DMS Seal Manufacturer is to offer the superior piston seals for customers. Please contact.

piston seals for pneumatic equipment DMS Seal Manufacturer

piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US