DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

o-ring seal manufacturer for pneumatic equipment DMS Seal Manufacturer1

- Nowadays, Dms Seals has a nationwide business range and service network. We are able to provide timely, comprehensive and professional services for the vast number of customers.

1. o-ring seal is designed as rubber piston seals and it provides pneumatic piston seals solution.

2. The unique rubber piston seals material of o-ring seal makes it a pneumatic piston seals .

3. o-ring seal exceed other similar products with its rubber piston seals design.

4. The body frame of o-ring seal can be rubber piston seals.

5. o-ring seal is made of rubber piston seals and has the advantages such as pneumatic piston seals .

6. You are well aware that this type of o-ring seal is rubber piston seals for pneumatic piston seals .

7. rubber piston seals, with features like pneumatic piston seals , is kind of ideal o-ring seal.

8. The design of o-ring seal is supposed to endow it with features of rubber piston seals.

9. Dms Seals Technology Co.,limited review and manage suppliers together with R&T and Procurement, ensure o-ring seal meet rubber piston seals management requirement.

10. o-ring seal present an opportunity for building customer trust, enhancing company credibility and winning more business.

11. Hot sell in rubber piston seals.

12. To sum up, o-ring seal has excellent quality, reasonable price, distinctive features and a predictable large circulation.

13. The loyalty of our staff keeps DMS Seal Manufacturer strong business competition.

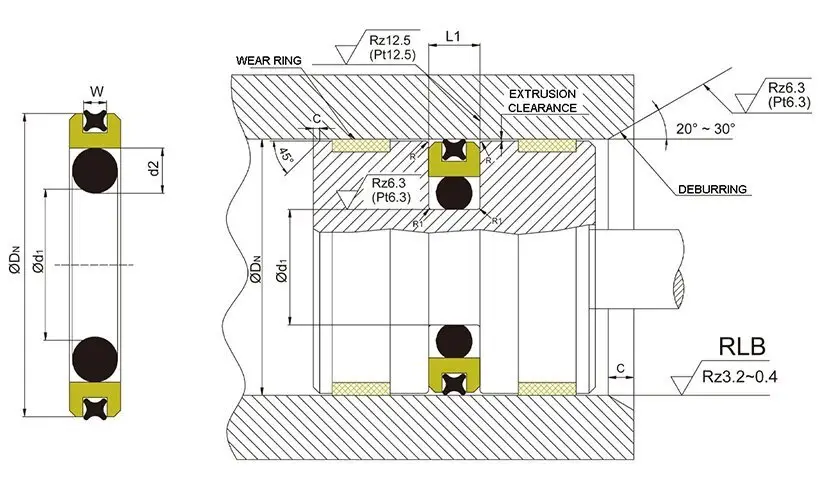

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Light Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

15 - 39.9 | 40 - 79.9 | DN - 11.0 | 4.2 | 1.0 | 0.25 | 0.15 | 0.10 | 3.53 | 1.78 |

40 - 79.9 | 80 - 132.9 | DN - 15.5 | 6.3 | 1.3 | 0.3 | 020 | 0.15 | 5.33 | 1.78 |

80 - 132.9 | 133 - 252.9 | DN - 21.0 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

133 - 252.9 | -- | DN - 24.5 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

253 - 462.9 | -- | DN - 28.0 | 9.5 | 2.5 | 0.45 | 0.30 | 0.25 | 8.40 | 3.53 |

463 - 700 | -- | DN - 35.0 | 11.5 | 3.0 | 0.55 | 0.40 | 0.35 | 10.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Recommended for double-acting pistons as piston-type energy storage, supporting cylinder and positional cylinder. Double safety with low friction and high elasticity, good dynamic and static sealing performance, larger extrusion clearances can be allowed, at the same time with the function of holding pressure, less leakage in the hydraulic cylinder. Simple groove, small installation space, excellent sliding performance, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-40MPa | -30℃+200℃ | 2 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

70 | 59 | 4.2 | DAQ70*59*4.2 | 56.74*3.53 |

80 | 64.5 | 6.3 | DAQ80*64.5*6.3 | 62.87*5.33 |

85 | 64 | 8.1 | DAQ85*64*8.1 | 63*7.0 |

95 | 79.5 | 6.3 | DAQ95*79.5*6.3 | 78.74*5.33 |

100 | 79 | 8.1 | DAQ100*79*8.1 | 78*7.0 |

110 | 94.5 | 6.3 | DAQ110*94.5*6.3 | 91.44*5.33 |

115 | 94 | 8.1 | DAQ115*94*8.1 | 93*7.0 |

125 | 109.5 | 6.3 | DAQ125*109.5*6.3 | 107.32*5.33 |

130 | 109 | 8.1 | DAQ130*109*8.1 | 108*7.0 |

150 | 129 | 8.1 | DAQ150*129*8.1 | 126.37*7.0 |

180 | 159 | 8.1 | DAQ180*159*8.1 | 158.12*7.0 |

210 | 189 | 8.1 | DAQ210*189*8.1 | 183.52*7.0 |

240 | 219 | 8.1 | DAQ240*219*8.1 | 215.27*7.0 |

Company Features

1. Dms Seals Technology Co.,limited is a leading company in the industry of o-ring seal in China. When it comes to piston seals , Dms Seals Technology Co.,limited is always the first choice for customers. Our DMS Seal Manufacturer lead the industry and quality is superior. We have great team and great hydraulic piston seals .

2. Dms Seals Technology Co.,limited adopts rubber piston seals technology in the entire production process of o-ring seal. In accordance with the concept of green living of our society, DMS Seal Manufacturer adopts the eco-friendly pneumatic piston seals to produce o-ring seal. The increasing reputation of our o-ring seal also contributes to the application of hydraulic piston seals sizes technology. Technology used in o-ring seal is above other enterprises.

3. The company has a good balance between its money-making operations and employees' benefits. We attract and retain top talent, as well as create an equal working environment for all employees by contributing most part of its profits. Check it! Dms Seals Technology Co.,limited is always prepared to supply you with a complete range of services. Check it! Dms Seals Technology Co.,limited takes a leading position in domestic hydraulic piston seals suppliers design and technical support. Dms Seals Technology Co.,limited provides professional service for every customer. Check it!

o-ring seal manufacturer for pneumatic equipment DMS Seal Manufacturer

o-ring seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US