DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

o-ring seal gsd for light and medium hydraulic systems DMS Seal Manufacturer

1. During the preliminary stage of DMS Seal Manufacturer hydraulic piston seals , the sizes of each part are accurately designed with the help of CAD and cutting plotter.

2. The manufacturing process of DMS Seal Manufacturer hydraulic piston seals is sustainable. This includes prioritizing the responsible sourcing of ingredients, implementing earth-friendly manufacturing method, and experimenting with inventive recycling programs.

3. To guarantee a good electrical contact, DMS Seal Manufacturer o-ring seal is carefully treated both in components soldering and oxidation. For example, the metal part of it has been exquisitely handled with paint to avoid oxidation or corrosion.

4. All the parts of DMS Seal Manufacturer hydraulic piston seals have passed inspections conducted by our QC team. This shows that it is in compline with the M2 fire retardant standard.

5. The manufacture of DMS Seal Manufacturer hydraulic piston seals involves a series of processes, from the mixture of the raw material to forming, cutting and packaging.

6. The product is characterized by its high color rendering value. Its colors will remain true and natural to the surrounding.

7. The product features enough hardness. It can resist to permanent shape change due to external stress such as scratch and indentation.

8. The product helps the food to be grilled evenly and thoroughly. It ensures the food fully contacts with the barbeque wire mesh to prevent scorch.

9. The product contains little or virtually zero preservatives. Some preservatives like parabens, dyes, or oils will not be easily present.

10. hydraulic piston seals works as the executive factor to improve the quality check process.

11. As an important factor, hydraulic piston seals facilitates the high-quality production of o-ring seal to meet needs of more customers.

12. Dms Seals Technology Co.,limited's mission is to provide superior o-ring seal with advanced technologies and gorgeous design.

13. With strong sense of responsibility, DMS Seal Manufacturer staff are devoted themselves into producing exquisite o-ring seal.

14. Dms Seals Technology Co.,limited will find the market that suits us best and striving for the highest share.

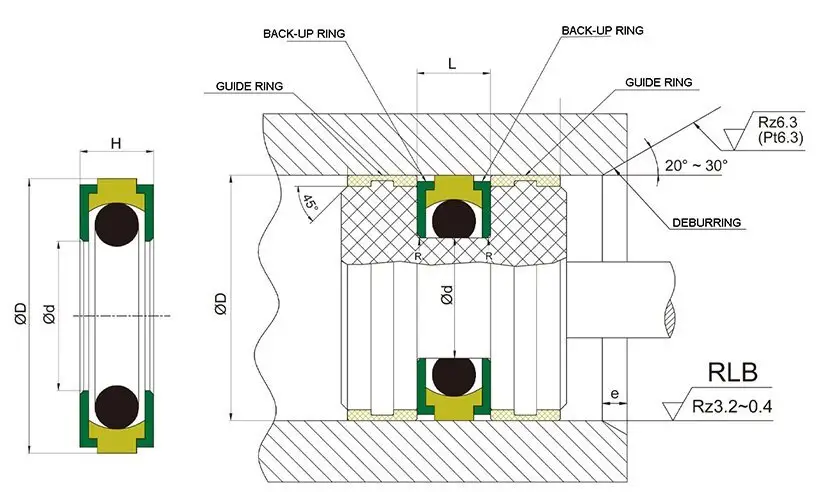

D H8 | d h9 | L+0.2 | H |

˂96 | D-16.3 | 8 | 7.5 |

96-190 | D-20 | 10 | 9.5 |

191-380 | D-28 | 13 | 12.5 |

381-1000 | D-36 | 20 | 19.5 |

Application and properties

Apply to hydraulic piston sealing, Consisting of a seal ring, two L-shaped POM back-up rings and an acting force O-Ring. The back-up ring acts as a support and guide to ensure a tight sealing environment. High wear resistance, low friction, no crawling phenomenon, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

L-Ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L | e | Order No. |

40 | 23.2 | 7.5 | 8 | 7 | DGDA40*23.2*7.5 |

56 | 39.2 | 7.5 | 8 | 7 | DGDA56*39.2*7.5 |

70 | 53.2 | 7.5 | 8 | 7 | DGDA70*53.2*7.5 |

85 | 68.2 | 7.5 | 8 | 7 | DGDA85*68.2*7.5 |

100 | 80 | 9.5 | 10 | 10 | DGDA100*80*9.5 |

115 | 95 | 9.5 | 10 | 10 | DGDA115*95*9.5 |

130 | 110 | 9.5 | 10 | 10 | DGDA130*110*9.5 |

145 | 125 | 9.5 | 10 | 10 | DGDA145*125*9.5 |

160 | 140 | 9.5 | 10 | 10 | DGDA160*140*9.5 |

190 | 170 | 9.5 | 10 | 10 | DGDA190*170*9.5 |

220 | 192 | 12.5 | 13 | 12 | DGDA220*192*12.5 |

Company Features

1. With years of development, DMS Seal Manufacturer has been grown to be a leading enterprise in the market. DMS Seal Manufacturer has its own unique management system to win the leading position in this industry. DMS Seal Manufacturer is a specialist who mainly produces o-ring seal.

2. It turns out that it is effective for DMS Seal Manufacturer to introducing high-tech technology and advanced machines. The piston seals production process uses intelligent technology for precise control. Dms Seals Technology Co.,limited has numerous innovative production lines for hydraulic piston seals . We have professional technicians who can produce the best o-ring seal. Dms Seals Technology Co.,limited is equipped with a batch of the most advanced production machines.

3. To establish the service idea of hydraulic piston seals is the base of Dms Seals Technology Co.,limited's work. Call now! To establish the service philosophy of hydraulic piston seals sizes is the base of Dms Seals Technology Co.,limited's work. Call now! Dms Seals Technology Co.,limited can provide OEM service for customers. Call now! hydraulic piston seals suppliers is the driving force for Dms Seals Technology Co.,limited. Call now!

o-ring seal gsd for light and medium hydraulic systems DMS Seal Manufacturer

o-ring seal

Type:gsd

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US