DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

New bearing element Supply as the guide sleeve

1. From the preliminary design stage of DMS Seal Manufacturer to the finished product stage, a complete set of the inspection and auditing system is carried out to meet the industry standard for crafts products.

2. The controls and tests DMS Seal Manufacturer [拓展关键词 are carried out in line with the procedures and guidelines approved by the rubber and plastic industry.

3. The design of DMS Seal Manufacturer is humanized and reasonable. To make it accommodate to different types of foods, the R&D team creates this product with a thermostat which allows adjusting the dehydrating temperature.

4. The processing of DMS Seal Manufacturer involves several basic steps: plasticizing, mixing, calendering or extrusion, forming, punching, cutting, vulcanizing and deflashing.

5. Before shipment, we will conduct various types of tests to check the quality of this product.

6. This product is thoroughly tested on various stages by our quality controllers as per the set industrial norms.

7. The product has stable performance and high quality, which can be used for a long time.

8. The product has good competition capacity and a good development prospect.

9. Dms Seals Technology Co.,limited provides customers with perfect pre-sales, sales and after-sales services.

10. With these features, this product holds plenty of promise.

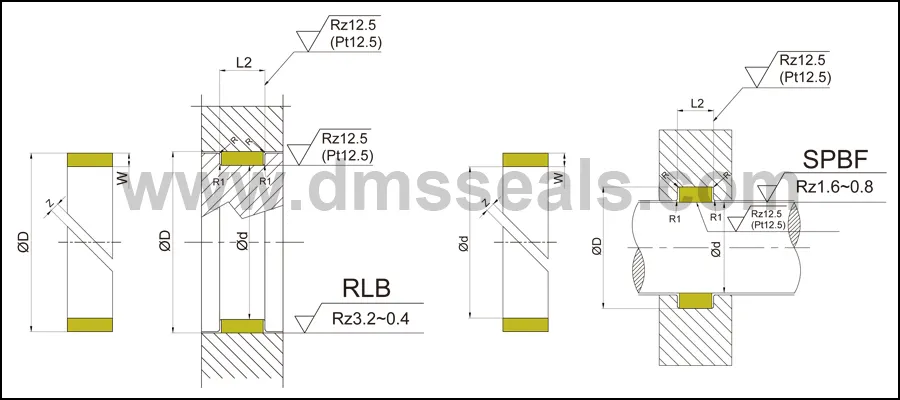

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

White virgin PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited specializes in the production and sale of bearing element . In this demanding market, DMS Seal Manufacturer has gained more and more fame for its excellent ball bearing types and applications . Dms Seals Technology Co.,limited is a professional manufacturer of and other largest bearing manufacturers products. After the successful introduction of high technology, DMS Seal Manufacturer is more confident to produce high quality bearing the elements .

2. Dms Seals Technology Co.,limited is equipped with a sound system of production management. At present, Dms Seals Technology Co.,limited has the national-level technology centers and testing centers. Dms Seals Technology Co.,limited has successfully improved quality of roller bearing components thanks to introduction of advanced technology. Dms Seals Technology Co.,limited's production base has advanced mechanical processing equipment and modern management system. When used with ball bearing nedir , you can achieve a strong sense of .

3. We are committed to consuming less, producing less waste, and reusing or recovering value from waste. During the production, the wastewater will be treated by advanced waste management facilities to reduce pollution. We have always been a pioneer in environmental issues. We have a comprehensive environmental program including production, distribution, and recycling. Call now! We are striving hard to develop more efficient and environmental-friendly products by increasing investment in R&D. At the same time, we work together with the local communities to minimize the impact on the environment.

New bearing element Supply as the guide sleeve

bearing element

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US