DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

loaded lip seal manufacturers for reciprocating piston rod or piston single acting seal

- Dms Seals always adheres to the service concept of 'quality first, customer first'. We return society with high-quality products and thoughtful services.

1. DMS Seal Manufacturer has passed compression and aging tests. These tests are conducted by our experienced technicians who utilize our state-of-the-art lab in order to monitor every aspect of production.

2. The production equipment of DMS Seal Manufacturer has been constantly upgraded for greater precision and efficiency. The equipment includes roll building machinery and extruder, mixing mill, surfacing lathes, milling machinery, and molding presses.

3. DMS Seal Manufacturer is designed in according to the ergonomics principle by the design team who have years of experience in creating BBQ accessories.

4. The design of DMS Seal Manufacturer is carried out by the in-house designers who hold qualifications and certifications in porcelain pattern making and creating.

5. To ensure the quality and safety of DMS Seal Manufacturer , the production process is constantly observed to ensure each of its ingredients does no harm to the end users.

6. The product has high stitch quality. It goes through stitches per inch (SPI) check to see the stitch density that may impact the strength, appearance, and performance of a garment seam.

7. The product is distinguished by high reliability. It has passed the stability test which is intended to check whether it's easy to fall or tip.

8. This product is not subject to loss of power due to frictional resistance. In the design phase, careful attention has been given to the matter of lubrication of all surfaces which moves in contact with others.

9. This product is free of tip-over hazards. Thanks to its strong and stable construction, it is not prone to wobble in any situation.

10. This product has the required safety. The Greenguard certification, a rigorous third-party certification, certifies that this product has low chemical emissions.

11. Not only the use of this product will be financially beneficial to the businesses but also it will attract more potential customers and will make the customer base strong and wider.

12. Using this product, One can easily accomplish many risky and heavy-duty tasks. This also helps to alleviate the pressure and labor of the workers.

13. This product will enhance the quality of life. It is convenient to use, and hence, can make life easier for people.

14. With its reliability, the product requires little repairs and maintenance, which will greatly help save operation costs.

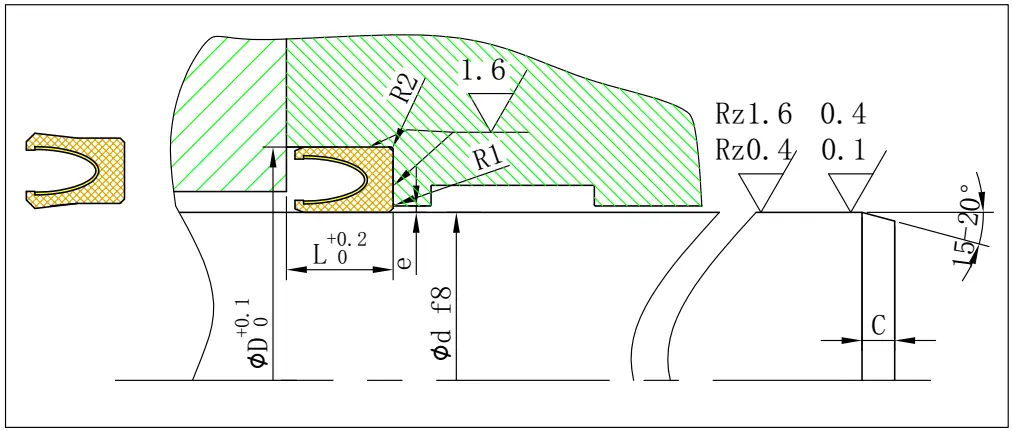

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited has strong technical strength and processing capabilities. Dms Seals Technology Co.,limited now is focusing on production of loaded lip seal . Since the establishment of Dms Seals Technology Co.,limited, we have been committed to producing rotary lip seal application . Dms Seals Technology Co.,limited is professional in the industry of high pressure seal design . As one of the famous mechanical shaft seals springs manufacturers, DMS Seal Manufacturer expects to be a leader in this field.

2. Our mechanical seal presentation supply is sufficient to guarantee demand owing to our advanced production line. Dms Seals Technology Co.,limited ranks top 10 when it comes to technology ability. There is a great progress in quality for mechanical seal problems with the help of technology.

3. It is a true portrayal of DMS Seal Manufacturer and it is also a realistic requirement for every DMS Seal Manufacturer person to keep spring energized seals in mind. Get price! Based on the idea of spring energized seal design , DMS Seal Manufacturer has always been standing at the strategic height to push forward implementation of the plans. Get price! The vision of Dms Seals Technology Co.,limited is formed by combining our unique culture, advantages, and strategic direction, which leads us to achieve a more beautiful new world. Get price! The stationary mechanical seal is the fundamental pursuit of enterprise development. Get price! Enthusiastically participating in the task of serving customers and creating value is important for DMS Seal Manufacturer in the future. Get price!

loaded lip seal manufacturers for reciprocating piston rod or piston single acting seal

loaded lip seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US