DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic piston seals for sale DMS Seal Manufacturer

1. DMS Seal Manufacturer hydraulic piston seals will go through quality assurance tests. It has passed electric component anti-fatigue testing, insulation level, energy-saving level, and electromagnetic safety test. DMS Seal manufacturer was established in 2008 and now has more than 10 years professional experience

2. Dms Seals Technology Co.,limited's customer service has high adaptability for different requirements. Seal we produced has applications in a wide range of fields

3. The product features an easy operation. It has a relatively simple operating system combining a powerful processing flow and provides simple operation instruction. High-end talents and advanced technology have enabled DMS o-ring seal quality to reach the industry's leading level

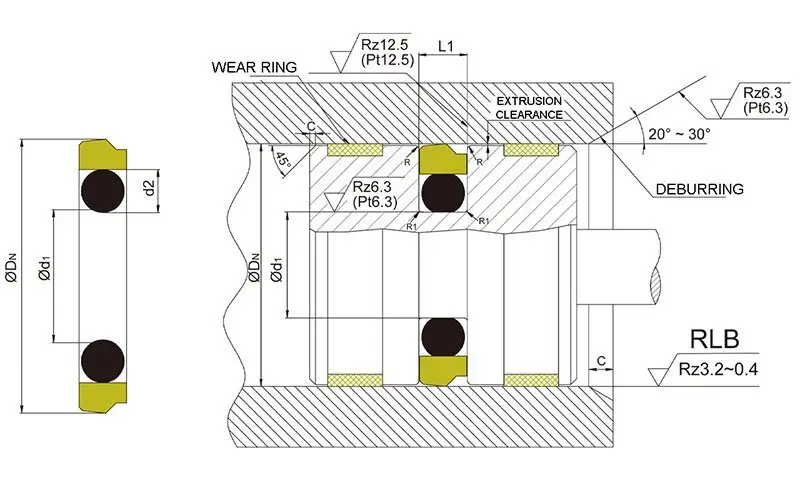

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-16.9 | 17-26.9 | -- | DN-4.9 | 2.2 | 0.4 | 0.30 | 0.20 | 0.15 | 1.78 |

17-26.9 | 27-59.9 | -- | DN-7.3 | 3.2 | 0.6 | 0.40 | 0.25 | 0.15 | 2.62 |

27-59.9 | 60-199.9 | 17-26.9 | DN-10.7 | 4.2 | 1.0 | 0.50 | 0.30 | 0.20 | 3.53 |

60-199.9 | 200-255.9 | 27-59.9 | DN-15.1 | 6.3 | 1.3 | 0.70 | 0.40 | 0.25 | 5.33 |

200-255.9 | 256-669.9 | 60-199.9 | DN-20.5 | 8.1 | 1.8 | 0.80 | 0.60 | 0.35 | 7.00 |

256-669.9 | 670-999.9 | 200-669.9 | DN-24.0 | 8.1 | 1.8 | 0.90 | 0.70 | 0.40 | 7.00 |

670-999.9 | -- | 256-669.9 | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | 1000-2000 | -- | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | -- | 670-999.9 | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

1000-2700 | -- | -- | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

Application and properties

Standard single acting sealing. Suitable for reciprocating environment, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are good, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Width | Order No. | O-ring Dimension |

D H9 | d1 h9 | L1+0.2 | ||

9 | 4.1 | 2.2 | GSD9*4.1*2.2 | 3.68*1.78 |

15 | 10.1 | 2.2 | GSD15*10.1*2.2 | 9.25*1.78 |

20 | 12.7 | 3.2 | GSD20*12.7*3.2 | 12.37*2.62 |

27 | 16.3 | 4.2 | GSD27*16.3*4.2 | 15.47*3.53 |

32 | 24.7 | 3.2 | GSD32*24.7*3.2 | 23.47*2.62 |

36 | 25.3 | 4.2 | GSD36*25.3*4.2 | 24*3.53 |

40 | 29.9 | 4.2 | GSD40*29.3*4.2 | 28.17*3.53 |

50 | 39.3 | 4.2 | GSD50*39.3*4.2 | 37.70*3.53 |

55 | 44.3 | 4.2 | GSD55*44.3*4.2 | 44.04*3.53 |

63 | 47.9 | 6.3 | GSD63*47.9*6.3 | 46.99*5.33 |

70 | 59.3 | 4.2 | GSD70*59.3*4.2 | 56.74*3.53 |

80 | 64.9 | 6.3 | GSD80*64.9*6.3 | 62.87*5.33 |

90 | 74.9 | 6.3 | GSD90*74.9*6.3 | 72.39*5.33 |

95 | 74.5 | 8.1 | GSD95*74.5*8.1 | 73*7.0 |

110 | 94.9 | 6.3 | GSD110*94.9*6.3 | 91.44*5.33 |

Company Features

1. Produced by the innovative machine, DMS Seal Manufacturer can guarantee the long service life of hydraulic piston seals .

2. Such business principles and strategic guidelines as hydraulic piston seals have been formed through the course of Dms Seals Technology Co.,limited's development. Ask online!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail: dms@dmsseals.com

PAY ATTENTION TO US