DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hydraulic hives type thrust bearing for business for sale

- Dms Seals has built a sound service system to provide one-stop services such as product consultation, professional debugging, skills training, and after-sales service.

1. DMS Seal Manufacturer hives type thrust bearing is produced in exclusive designs with maximum finishes that are subject to exhaustive quality control checks, meeting the sanitary ware quality standards.

2. Every ingredient of DMS Seal Manufacturer has undergone a strict antimicrobial effectiveness test and is scientifically assessed by our professional QC team.

3. Before the delivery of DMS Seal Manufacturer , it will be checked by our well-qualified engineers and technicians to ensure its cooling effect and the availability of refrigerants.

4. DMS Seal Manufacturer is finished by adopting test equipment that measures the dynamic behavior of compound and simulates the behavior in different temperature environments.

5. The design of DMS Seal Manufacturer hives type thrust bearing is conducted via differential analysis and screening, including power consumption, light source stability, and luminous efficiency.

6. This product features robustness. The metal material is well known for its robust property especially when exposed to strong impact, it is not easy to bend or crack.

7. The product features strong compatibility. It doesn't just work alone. Other function like credit card verification can be added to work with the system.

8. The product has less microbial contaminants. Produced in the dust-free workshop, the microbial contaminations can not easily get into this product.

9. Dms Seals Technology Co.,limited has the advanced product testing method and equipment.

10. Our mature sales network contributes to the popularity of DMS Seal Manufacturer.

11. DMS Seal Manufacturer is very proud to produce such a popular hives type thrust bearing in the industry.

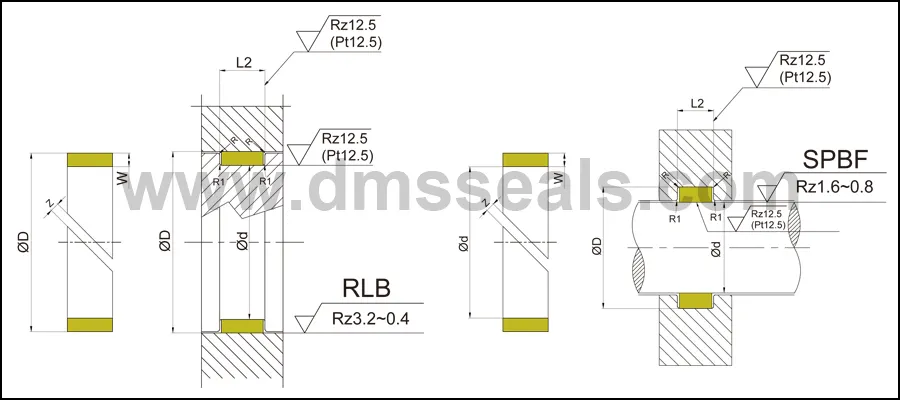

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Phenolic resin

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | 0-100 MPa | -60℃ +120℃ | 1 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Standard groove width and standard thickness

Standard groove width

Groove width L2 | 8.1 | 10 | 15 | 20 | 5.6 | 6.3 | 9.5 | 9.7 | 12.7 | 25 | 30 | 40 | 50 | 5 | 6 | 8 | 35 | 45 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 2 | 2.5 | 3 | 3.5 | 4 | 6 | 3.18 | 3.17 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited is a mature Chinese company. Our design and manufacture of is a specialty we are particularly proud of. Dms Seals Technology Co.,limited is a prestigious manufacturer in the China market, with remarkable abilities in developing and producing quality . Dms Seals Technology Co.,limited dedicates to the design and production of . We are a manufacturer with abundant experience and innovative designs.

2. We have an in-house quality check team. They follow a strict inspection process to make sure that all our products are checked multiple times in many phases, ensuring the highest quality of the product. The factory carries out strict quality and production management control systems. These systems require all of the incoming materials, parts, production techniques, and packaging ways to be tested and controlled to meet standards. Covering a large area, our plant provides enough space for the storage of our raw materials. This means that our time spent on the parchment of materials has been greatly reduced and the delivery time can be ahead of schedule. Our big and wide factory is well-organized inside in a thorough manner. It includes various kinds of advanced machines, which allows us to smoothly finish our production projects. Our factory is located in a favorable geographic position. This strategic location helps us to connect businesses competently along with quality products that meet customers’ requirements.

3. We strive for a culture of integrity in our people, partners, and suppliers. To this end, we have established a dedicated ethics and compliance program to ensure that ethical and compliant behavior is deeply embedded throughout the company. Welcome to visit our factory! Our promise of value is based on innovative design, impeccable engineering, outstanding execution and excellent service within budget and schedule. Welcome to visit our factory! The company's stated promise is ' To give the best service, make the best quality products'. We are working on cultivating a professional team of staff who can provide world-class customer service. Welcome to visit our factory! We are committed to annual donations to the local construction of a school or medical center. We are working hard to benefit more people from our social caring projects. Dms Seals Technology Co.,limited will provide you with more professional, more wonderful, more perfect service. Welcome to visit our factory!

hydraulic hives type thrust bearing for business for sale

hives type thrust bearing

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US