DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

hot sale rod seal supplier

1. The production of DMS Seal Manufacturer is in compliance with the accepted international standards.

2. The design of DMS Seal Manufacturer can be customized to meet various target markets.

3. The specifications of rod seal can be customized according to customer needs.

4. DMS Seal Manufacturer is designed by professionals and made of well-selected materials.

5. The product is characterized by a smooth surface. The blister, air bubbles, cracks, or burrs have been all totally removed from the surface.

6. This product features wear comfort. Factors affecting the comfort properties of fibers and fabrics are seriously taken into consideration and integrated it to its design.

7. This product features good moisture management. Materials can achieve such properties as water vapor permeability and short-time water vapor absorbency are used for this product.

8. This product can support foot movement stably. Its ergonomic structure can effectively withstand the stress from the feet by locking the shoe around the heel.

9. This product is wrinkle resistant. Its fabrics featuring strong elasticity and frictional resistance to inhabit any change in its shape.

10. After many years of development, Dms Seals Technology Co.,limited has been recognized by customers for its good reputation and excellent quality.

11. Dms Seals Technology Co.,limited applies excellent customer service policy and standard procedures.

12. Dms Seals Technology Co.,limited has been rapidly developed and recognized by the society.

13. Through unremitting efforts, Dms Seals Technology Co.,limited has made great achievements in improving customer experience.

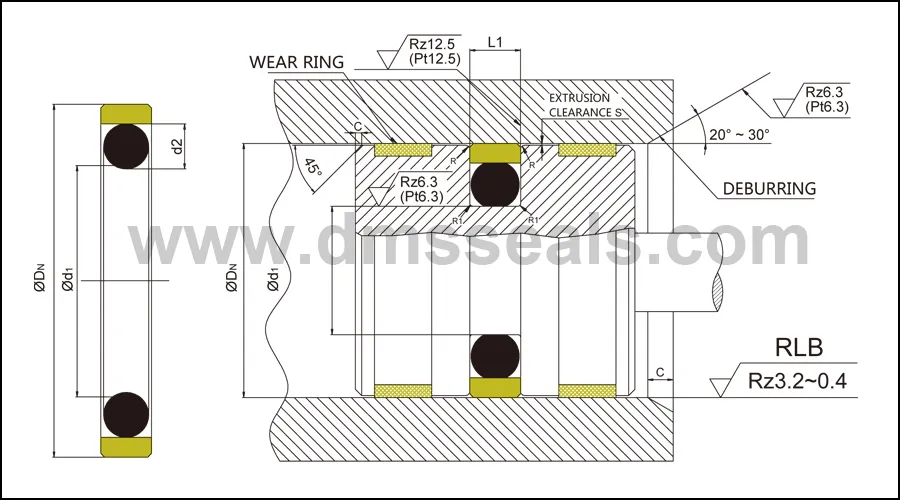

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. Dms Seals Technology Co.,limited is a professional manufacturer and supplier for rod seal . Dms Seals Technology Co.,limited is one of mechanical seal construction industry leaders, mainly engaged in production and sales of Others. Dms Seals Technology Co.,limited is the main supplier for piston rings by bore size at home and abroad.

2. We have a team of professional designers to ensure the best design of products. Combining their years of design expertise with unique design ideas, they are able to design products with the most innovative shapes. We have set up a professional manufacturing team. They have innovative approaches to manufacturing problems and are involved in many elements of our products to create solutions. We have a dense network of satisfied customers around the world. These customers complement our global business by bringing our products to world markets. Just like our customers, our business covers the world. We don't believe in the boundaries, especially in trade. Customers can leverage our world-market expertise to gain a competitive edge. We have a responsible quality team. They control and verify the compliance of products with company standards and international standards through production process audits product audits and post-event audits.

3. The staff of DMS Seal Manufacturer always keeps customer service in mind. Get an offer! DMS Seal Manufacturer insists on development concept of to be an eye-catching enterprise. Get an offer! Dms Seals Technology Co.,limited will tightly keep in mind and better serve customers. Get an offer! Dms Seals Technology Co.,limited will accelerate the pace of R&D and the launch of new products. Get an offer! Dms Seals Technology Co.,limited has always followed our enterprise spirit of . Get an offer!

hot sale rod seal supplier

rod seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US