DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

High-quality roller ball bearing sizes wear ring for sale

- Dms Seals insists on the service principle to be active, efficient and considerate. We are dedicated to providing professional and efficient services.

1. DMS Seal Manufacturer roller ball bearing sizes designed by a group of experts, combines aesthetic look and practicality.

2. DMS Seal Manufacturer is fabricated using quality raw materials and advanced production technology.

3. DMS Seal Manufacturer is manufactured using state-of-the-art technology based on the principles of lean production.

4. The product has been rigorously tested on various aspects and its quality has been recognized by professional QC team.

5. Equipped with advanced facilities, we focus more on the quality assurance.

6. The product is qualified with international quality standards.

7. The product is of great quality which has been approved by the international certifications.

8. Our product has a wide client base across China and overseas.

9. The reputation and competitiveness of this range has raised apparently in recent years.

10. This product is attached to the latest market development and trends.

11. The product presents an opportunity for building customer trust and winning more business.

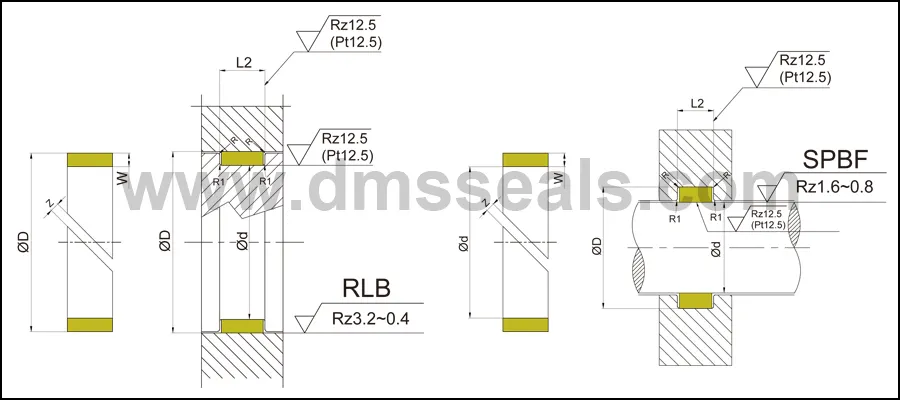

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Filled PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited has a very wide range of products. Our roller ball bearing sizes has exported to many countries and received many positive feedbacks. Dms Seals Technology Co.,limited is a global leading roller bearing distributors company having its own large-scale manufacture base. Fully complementing the development policy and adjusting the shift changes make DMS Seal Manufacturer grow rapidly.

2. We operate our business by utilizing up-to-date production facilities. These facilities are imported from the United States, Japan, Germany, etc. With their advanced technologies, our production plan can be ensured. One of our important capacities is our R&D team. They mainly specialize in research and development of customized and high-performance product solutions. The team is a strong backup force in our company. We possess a series of state-of-the-art manufacturing facilities. Undergoing routine inspections, these facilities are able to maintain its good conditions, supporting the whole production process. We are backed by professional manufacturing and engineer teams. They proactively apply their extensive experience and resources to help our business achieve sustainable rapid growth. Our factory owns a comprehensive range of manufacturing machines. These machines are developed adopting cutting-edge technologies and hence feature high accuracy and efficiency. This enables us to manage throughout the entire production flow precisely.

3. A sound environment is the foundation of business success. We'll set our actions to gear towards achieving sustainable development, such as reducing waste and conserving energy resources. We are continually audited and monitored by our customers to ensure that our high standards are maintained throughout all of our processes. Inquiry! It’s no secret we strive for the best and this is why we do everything in house. Having control of our products from start to finish is important to us so we can make sure customers receive products just as we intended them. Inquiry!

High-quality roller ball bearing sizes wear ring for sale

roller ball bearing sizes

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US