DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

High-quality o-ring seal manufacturers in highly aggressive chemical processing

- Dms Seals constructs a scientific management system and a complete service system. We strive to provide customers with personalized and high-quality services and solutions to meet their different needs.

1. The quality inspection for DMS Seal Manufacturer covers several parts. It will be scrutinized for its strength, anti-bending capability, fineness, color aberration, and thermal stability.

2. DMS Seal Manufacturer has been tested by the third-party organization. It has passed through an electrical test, high current bond test, insulation test, leakage current test, and load test.

3. DMS Seal Manufacturer o-ring seal is tested with great rigor. Requirements and functionalities stipulated in product planning are crucial determining factors when it comes to the necessary tests.

4. The manufacture of DMS Seal Manufacturer adopts a variety of methods to cut and join tensile fabrics, such as advanced sail-making techniques.

5. This product has the advantage of strong corrosion resistance. The surface of it has been processed with special oxidization and plating technique.

6. The product features great electromagnetic compatibility. It has the ability to function satisfactorily in its electromagnetic environment without introducing intolerable electromagnetic disturbance to anything in that environment.

7. The product is safe enough to use. The dangers of electric leakage have been eliminated during production and all electrical components complying with relevant standards of EN or IEC.

8. The product stands out for its high safety during the operation. Because it has automatic break protection from power leakage and short circuit.

9. The product won't become a problem or a nuisance after over-used or frequent switch on/off. It provides desirable visibility.

10. The product is beneficial in helping clinicians and healthcare practitioners make better diagnoses so that patients can get faster treatment.

11. The product is extremely easy to clean and maintain and can be cleaned with normal soap or a cleaning liquid.

12. The product has excellent hand touch feeling. People will find that it is smooth to touch without burrs feeling.

1. Installation Recommendation

2. Application and properties

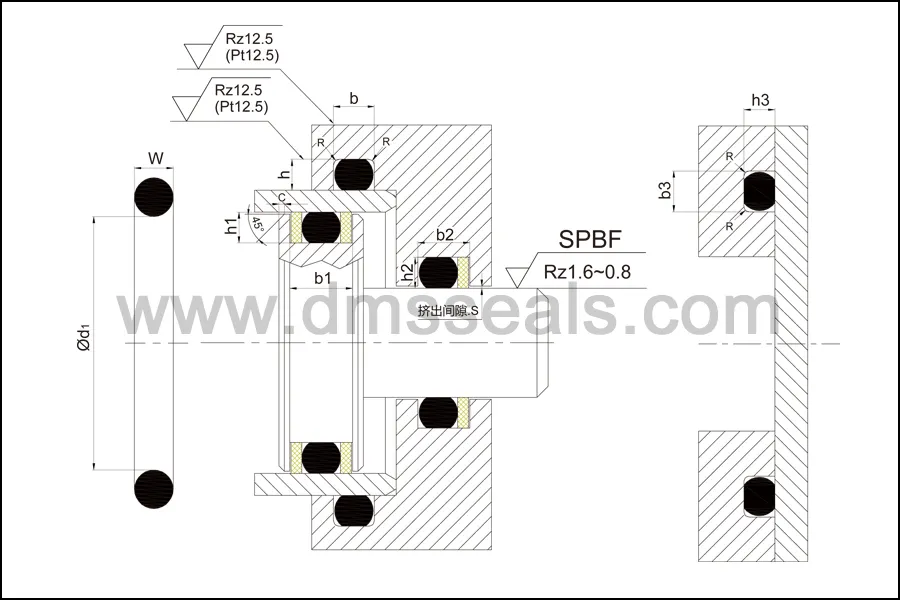

Double acting seals, the sealing effect is achieved by the deformation of the section of the O-Rings, and the deformation is determined by the depth of the installation groove. Under pressure, the O-ring has a large surface tension like liquid, used for static sealing more. It is only recommended for better conditions in dynamic applications. System lubrication, pressure, temperature, sealing clearance, speed, medium and surface quality of metal parts determine the service life of O-Rings. It is not recommended if the lubrication is not sufficient during rotary motion.

3. Standard materials

Silicone

4. Performance parameter

Static Seal | Dynamic Seal | |

Working Pressure | No support ring, up to 20MPa; With the support ring, up to 40MPa; With special support ring, up to 200MPa. | No support ring, up to 5MPa; With the support ring, higher pressure. |

Movement Speed | Maximum reciprocating speed up to 0.5m / s; maximum rotation speed up to 2.0m/s. | |

Temperature | NBR: -30℃ - 100℃; FKM: -20℃ - 220℃. | |

5. Wire Diameter Tolerance

Wire diameter of O-Ring (mm) | Tolerance (±mm) |

0-1.8 | 0.08 |

1.80-2.65 | 0.09 |

2.65-3.55 | 0.10 |

3.55-5.30 | 0.13 |

5.30-7.00 | 0.15 |

7.00-8.00 | 0.18 |

8.00-10.00 | 0.21 |

10.00-12.00 | 0.25 |

6. Inner diameter tolerance

Inner Diameter d1 mm | Tolerance ±mm | Inner Diameter d1 mm | Tolerance ±mm | Inner Diameter d1 mm | Tolerance ±mm |

0.70-2.50 2.50-4.50 4.50-6.30 | 0.13 0.14 0.15 | 43.70-45.00 46.00-46.20 46.20-47.50 | 0.42 0.43 0.44 | 95.00-97.50 97.50-100.00 100.00-103.00 | 0.83 0.84 0.87 |

6.30-8.50 8.50-10.00 10.00-11.20 | 0.16 0.17 0.18 | 47.50-48.70 48.70-50.00 50.00-51.50 | 0.45 0.46 0.47 | 103.00-106.00 106.00-109.00 109.00-112.00 | 0.89 0.91 0.93 |

11.20-14.00 14.00-16.00 16.00-18.00 | 0.19 0.20 0.21 | 51.50-53.00 53.00-54.50 54.50-56.00 | 0.48 0.50 0.51 | 112.00-115.00 115.00-118.00 118.00-122.00 | 0.95 0.97 1.00 |

18.00-20.00 20.00-21.20 21.20-23.60 | 0.22 0.23 0.24 | 56.00-58.00 58.00-60.00 60.00-61.50 | 0.52 0.54 0.55 | 122.00-125.00 125.00-128.00 128.00-132.00 | 1.03 1.05 1.08 |

23.60-25.00 25.00-26.50 26.50-28.00 | 0.25 0.26 0.28 | 61.50-63.00 63.00-65.00 65.00-67.00 | 0.56 0.58 0.59 | 132.00-136.00 136.00-140.00 140.00-145-00 | 1.10 1.13 1.17 |

28.00-30.00 30.00-31.50 31.50-33.50 | 0.29 0.31 0.32 | 67.00-69.00 69.00-71.00 71.00-73.00 | 0.61 0.63 0.64 | 145.00-150.00 150.00-155.00 155.00-160.00 | 1.20 1.24 1.27 |

33.50-34.50 34.50-35.50 35.50-36.50 | 0.33 0.34 0.35 | 73.00-75.00 75.00-77.50 77.50-80.00 | 0.66 0.67 0.69 | 160.00-165.00 165.00-170.00 170.00-175.00 | 1.31 1.34 1.38 |

36.50-37.50 37.50-38.70 38.70-40.00 | 0.36 0.37 0.38 | 80.00-82.50 82.50-85.00 85.00-87.50 | 0.71 0.73 0.75 | 175.00-180.00 180.00-185.00 185.00-190.00 | 1.41 1.44 1.48 |

40.00-41.20 41.20-42.50 42.50-43.70 | 0.39 0.40 0.41 | 87.50-90.00 90.00-92.50 92.50-95.00 | 0.77 0.79 0.81 | 190.00-195.00 195.00-200.00 200.00-206.00 | 1.51 1.55 1.59 |

206.00-212.00 212.00-218.00 224.00-230.00 | 1.63 1.71 1.75 | 325.00-335.00 335.00-345.00 345.00-355.00 | 2.43 2.49 2.56 | 500.00-515.00 515.00-530.00 530.00-545.00 | 3.54 3.63 3.72 |

230.00-236.00 236.00-243.00 243.00-250.00 | 1.79 1.83 1.88 | 355.00-365.00 365.00-375.00 375.00-387.00 | 2.62 2.68 2.76 | 545.00-560.00 560.00-580.00 580.00-600.00 | 3.81 3.93 4.05 |

250.00-258.00 258.00-265.00 265.00-272.00 | 1.93 1.98 2.02 | 387.00-400.00 400.00-412.00 412.00-425.00 | 2.84 2.91 2.99 | 600.00-615.00 615.00-630.00 630.00-650.00 | 4.13 4.22 4.34 |

272.00-280.00 280.00-290.00 290.00-300.00 | 2.08 2.14 2.21 | 425.00-437.00 437.00-450.00 450.00-462.00 | 3.07 3.15 3.22 | 650.00-670.00 | 4.46 |

300.00-307.00 307.00-315.00 315.00-325.00 | 2.25 2.30 2.37 | 462.00-475.00 475.00-485.00 485.00-500.00 | 3.30 3.37 3.45 |

Company Features

1. Dms Seals Technology Co.,limited is successfully operating the business in designing and manufacturing . We differentiate ourselves with years of experience. Dms Seals Technology Co.,limited is a leading manufacturer of in China. We pride ourselves in gaining a reputation through our extensive experience. Dms Seals Technology Co.,limited has grown and prospered, occupying a crucial role in the developing and manufacturing of in the market.

2. Staff working in Dms Seals Technology Co.,limited are all well-trained. o-ring seal is assembled by our highly skilled professionals. Dms Seals Technology Co.,limited owns a professional team of technicians to keep improving our high pressure o ring seals . We have a top R&D team to keep improving quality and design for our oil seal ring . Almost all technician talent for the industry of o ring seal kit work in our Dms Seals Technology Co.,limited.

3. Our company bears social responsibility. We support initiatives and organizations such as Sustainable Coalition, Canopy and Zero Discharge of Hazardous chemicals (ZDHC). Our company is engaged in sustainable management. We regularly discuss strategies in order to accurately grasp the changes in the social needs of the international community and reflect them in management from a long-term perspective. We bear social responsibility. We fulfill our social and environmental responsibility through each of our products. We endeavor to do our part in our company. We take into account our social and environmental obligations to the local communities around our plant.

High-quality o-ring seal manufacturers in highly aggressive chemical processing

o-ring seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US