DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

High-quality hydraulic and pneumatic seals for pressure work and sliding high speed occasions

1. The design of DMS Seal Manufacturer hydraulic and pneumatic seals takes many factors into consideration. They are physical safety, surface property, ergonomics, stability, strength, durability and so forth.

2. The fabrics of DMS Seal Manufacturer are selected considering many factors. They mainly include a variety of weight, textures, patterns, and hand feel.

3. The design of DMS Seal Manufacturer is conducted meticulously. It is carried out on the choice of drawing paper, a pen, color, computer, and other tools and the pen line is used to depict shoe line drawings.

4. The raw materials used in DMS Seal Manufacturer hydraulic and pneumatic seals are carefully selected. They are required to be handled (cleaning, measuring, and cutting) in a professional way to achieve the required dimensions and quality for furniture manufacturing.

5. Stringent quality and safety standards are set for DMS Seal Manufacturer . They are physical performance testing, toxic and hazardous substance testing, fire testing, and others.

6. The product is innoxious. It has passed the chemical properties test, which verifies that it contains no dimethyl fumarate, carcinogenic and allergy-inducing dyes, and azo dyes.

7. This product has the desired dimensional stability. It won't be distorted, twisted or shorten in length and width after washing or other wet processing.

8. This product has a perfect shape. It is designed following the natural curves of the figure, make darts, side seams and the hollow of the back.

9. The product is safe. It has been tested using pH test strips to make sure that the pH level of the fabric ingredients is controlled to the level similar to the surface layer of human skin.

10. This product can help people finish tasks that are too heavy or difficult. It significantly reduces the work burden for people.

11. This well-made product is not only a personal hallmark of fashion icons but also it reflects people's personality and confidence in themselves.

12. Having this product helps people keep all the stuff in place in the kitchen. Since it’ll be more spacious, cleaning the whole kitchen will be very easy.

13. This kind of material will make shoes that allow the foot the breathe, which is especially important for athletes who are constantly on the move.

14. This product can flexibly adapt to the changing working requirements. It can meet the specific needs and workload.

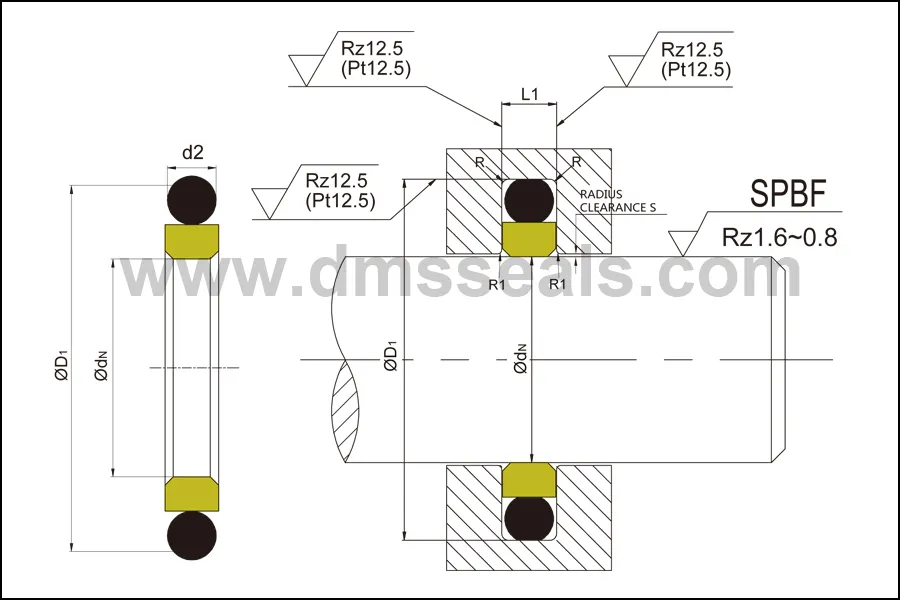

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-225.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion environment, a wide range of fluids and high temperature condition. Suitable for larger gap of piston rod. Low friction, simple groove, be able to work in themedium with oil spots.

Meet the standard of GB/T 15242.3.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSI20*27.3*3.2 GSI20*30.7*4.2 GSI22*29.3*3.2 | 21.89*2.62 25.0*3.53 25.07*2.62 |

22 24 25 | 32.7 31.3 32.3 | 4.2 3.2 3.2 | GSI22*32.7*4.2 GSI24*31.3*3.2 GSI25*32.3*3.2 | 26.57*3.53 26.64*2.62 28.24*2.62 |

25 26 28 | 35.7 36.7 35.3 | 4.2 4.2 3.2 | GSI25*35.7*4.2 GSI26*36.7*4.2 GSI28*35.3*3.2 | 29.74*3.53 29.74*3.53 29.82*2.62 |

28 30 30 | 38.7 37.3 40.7 | 4.2 3.2 4.2 | GSI28*38.7*4.2 GSI30*37.3*3.2 GSI30*40.7*4.2 | 32.92*3.53 32.99*2.62 34.52*3.53 |

32 32 35 | 39.3 42.7 42.3 | 3.2 4.2 3.2 | GSI32*39.3*3.2 GSI32*42.7*4.2 GSI35*42.3*3.2 | 34.59*2.62 36.09*3.53 37.77*2.62 |

35 36 36 | 45.7 43.3 46.7 | 4.2 3.2 4.2 | GSI35*45.7*4.2 GSI36*43.3*3.2 GSI36*46.7*4.2 | 37.69*3.53 39.34*2.62 40.87*3.53 |

38 38 40 | 48.7 53.1 50.7 | 4.2 6.3 4.2 | GSI38*48.7*4.2 GSI38*53.1*6.3 GSI40*50.7*4.2 | 40.87*3.53 43.82*5.33 44.04*3.53 |

Company Features

1. As culture developed, DMS Seal Manufacturer was developing its innovative capability to make hydraulic and pneumatic seals . Dms Seals Technology Co.,limited has been engaged in the production of viton rubber seal since its establishment. Known as a professional hydraulic cylinder gaskets manufacturer, Dms Seals Technology Co.,limited has a wide market share.

2. We have the capability of researching and developing state-of-the-art technologies of hydraulic piston cup seals . Dms Seals Technology Co.,limited is equipped with strong research strength, having an R&D team dedicated to developing all types of new u seal design . Our professional equipment allows us to fabricate such . Quality is above everything in Dms Seals Technology Co.,limited.

3. The DMS Seal Manufacturer brand is also designed to get higher recommendations from customers. Check it! DMS Seal Manufacturer can give customers more value than other brands. Check it! Dms Seals Technology Co.,limited will continue to strive for excellence. Check it!

High-quality hydraulic and pneumatic seals for pressure work and sliding high speed occasions

hydraulic and pneumatic seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US