DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

High-quality buffer seal hydraulic with ptfe nbr and pom for light and medium hydraulic systems

1. DMS Seal Manufacturer has undergone extensive tests regarding its performance. It has been tested in terms of resistance, temperature resistance, adhesion/anti-slip resistance, and bacteria resistance.

2. In line with furniture compliance, DMS Seal Manufacturer is manufactured under strict quality control. It will be inspected in terms of comfort level, safety, structural stability, flame retardant resistance, and wear resistance.

3. DMS Seal Manufacturer is tested in terms of performance and manufacturing quality. It has passed various tests, such as anti-bacterial testing, temperature resistance, colorfastness, tensile strength, and wear resistance.

4. DMS Seal Manufacturer has been assessed in many aspects. They are stitching & seam strength, fabric construction, embellishments, colorfastness, dimension stability, and durability.

5. buffer seal hydraulic is of such excellent properties as , which deserves popularization and application in the field of .

6. By integrating and , Dms Seals Technology Co.,limited is able to produce finest buffer seal hydraulic .

7. Years of application of buffer seal hydraulic proves the good performances and the good application effect of it.

8. Through electroluminescence, the product has made a significant contribution to protecting the environment while reducing electricity demand.

9. With the benefit of increasing production efficiency and output, the product is widely applied in the production of many industries.

10. It remains flat rather than wrinkled after washing, which will help keep the bed looking neat and tidy. And users will not have to worry about the shrinkage.

11. It is able to wick the moisture away from the skin, keeping users' temperature regulated and leaving them drier and cozier throughout the night.

12. It helps users relax and fall asleep faster. With a lightweight, smooth feel, users are sure to get the rest they've been dreaming of.

Application and properties

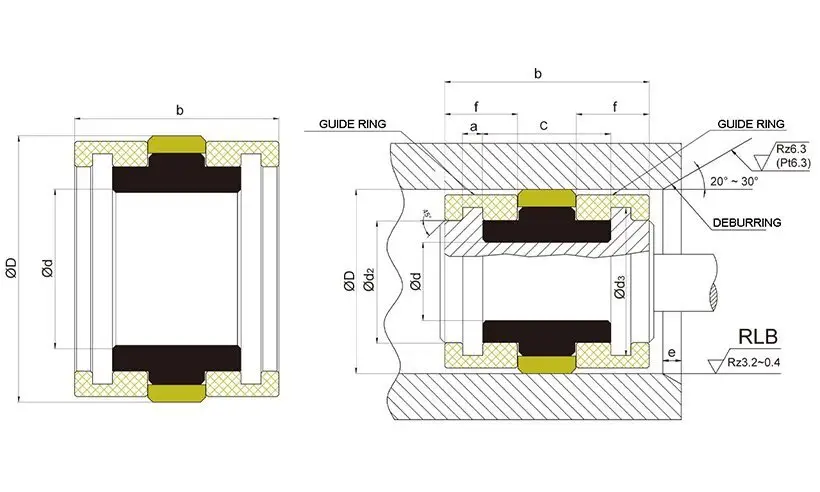

Apply to cylinder piston,Consisting of a seal ring, an O-Ring, a pair of retaining rings and a pair of guide sleeves. The seal ring and cylinder bore conforming to be a symmetric section to achieve the sealing performance, with double acting sealing performance.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Guide ring: filled PTFE / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1 m/s | hydraulic oil, water and emulsion |

D | d | b | d2 | d3 | a | c | f | e | Order No. |

40 | 26 | 30 | 32 | 36 | 3.5 | 15.5 | 7.25 | 7 | DKDF40*26*30 |

56 | 40 | 32 | 48 | 52 | 3 | 20.5 | 5.8 | 7 | DKDF56*40*32 |

65 | 49 | 32 | 57 | 61 | 3 | 20.5 | 5.8 | 7 | DKDF65*49*32 |

80 | 62 | 36 | 72 | 76 | 3 | 22.5 | 6.8 | 7 | DKDF80*62*36 |

95 | 77 | 36 | 87 | 91 | 3 | 22.5 | 6.8 | 7 | DKDF95*77*36 |

110 | 92 | 36 | 102 | 106 | 3 | 22.5 | 6.8 | 10 | DKDF110*92*36 |

125 | 103 | 43 | 115 | 121 | 4 | 26.5 | 8.3 | 10 | DKDF125*103*43 |

140 | 118 | 43 | 130 | 136 | 4 | 26.5 | 8.3 | 10 | DKDF140*118*43 |

155 | 133 | 43 | 145 | 151 | 4 | 26.5 | 8.3 | 10 | DKDF155*133*43 |

180 | 158 | 48 | 170 | 176 | 6 | 26.5 | 10.8 | 10 | DKDF180*158*48 |

200 | 175 | 48 | 190 | 196 | 4.5 | 31.5 | 8.3 | 10 | DKDF200*175*48 |

235 | 210 |

| 225 | 231 | 15 | 31.5 | 21.3 | 12 | DKDF235*210*74 |

265 | 240 | 74 | 255 | 261 | 15 | 31.5 | 21.3 | 12 | DKDF265*240*74 |

Company Features

1. DMS Seal Manufacturer has made great achievements in buffer seal hydraulic business. Dms Seals Technology Co.,limited is a professional producer for manufacturing oil seal hydraulic . With a large-scale factory and professional production line, Dms Seals Technology Co.,limited is considered a reliable supplier of piston cup seal suppliers .

2. With excellent staff and advanced equipment, our cylinder rod seal has won the recognition of more customers. As the pioneer in transmission piston seal industry, the products provided by DMS Seal Manufacturer enjoy high reputation. As the model of shaft wiper seal industry, DMS Seal Manufacturer is able to offer customers the best products with high performance.

3. We promise quick lead times. Our workflow, from initial design to production management, allows for even quicker fast track lead times when necessary. No one works harder or faster to help you achieve your production goals. Contact! Our vision is to expand our global business. We will strive hard to achieve this goal by improving our product quality and introducing talents. Contact! Our company bears social responsibilities. By reducing lead time and material waste, we have achieved less hazardous byproducts and energy consumption.

High-quality buffer seal hydraulic with ptfe nbr and pom for light and medium hydraulic systems

buffer seal hydraulic

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US