DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

high efficiency scraper seals supplier for injection molding machines

1. The design of DMS Seal Manufacturer metric wiper seal mainly follows 3 principles. They are respectively the Principle of Theme, the Principle of Humanization and the Principle of Science.

2. Production of DMS Seal Manufacturer metric wiper seal uses advanced manufacturing equipment. It is processed by vacuum cleaning equipment, washing machine, and other special textile equipment.

3. The manufacture of DMS Seal Manufacturer metric wiper seal provides printing options. The flexographic print process is commonly used for printing on this product. In recent years the digital direct print is entering the market offering new possibilities.

4. The design of DMS Seal Manufacturer metric wiper seal covers many factors. They mainly include statics and dynamics effect, parts tolerances and deformation, size stability, etc.

5. The product features good deformation resistance. When a sufficient load from a machine is applied to it, it will not happen to change shapes.

6. This product features stability and cracks resistance. Compared with ordinary alternatives, the moisture ratio is strictly controlled to prevent dry cracking during production.

7. The product has a long service life. All of its components or parts are made of high-quality materials which are able to withstand daily heavy use. [卖点、特色句

8. The product features excellent flexibility at low temperatures. It has passed two main low-temperature tests such as low-temperature brittleness test and temperature retraction test.

9. The product has a long service life. The end face of the product is made of self-lubricating and wear-resistant material composition which enhances its wearability.

10. Because of having a lot of merits, it is for sure that the product will have a bright market application future.

11. Its huge market prospects have helped DMS Seal Manufacturer attracted more and more customers in the industry.

12. This product price has the competition ability, deeply the market welcome, has the huge market potential.

13. The product has won a good reputation and trust of users and has a huge market application future.

14. It is customizable with various specifications in tune with the need of the clients.

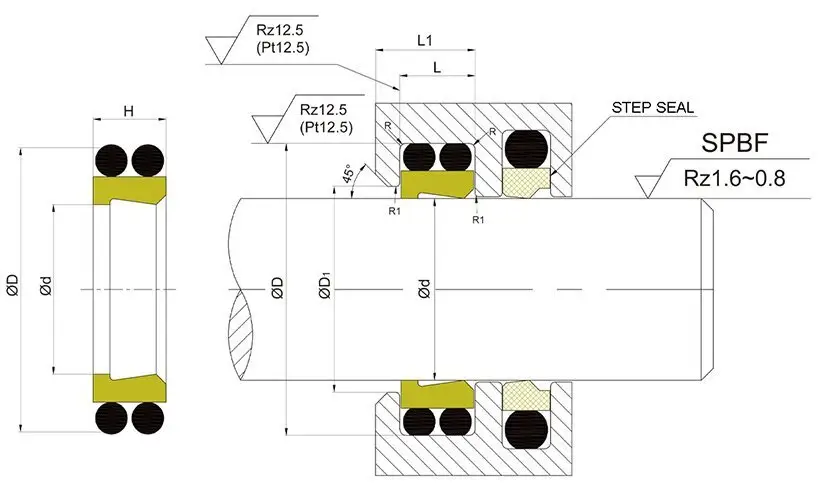

Rod Diameter | Groove Diameter | Groove Width | Bore Diameter | Radius | Step Width |

d f8/h9 | D H9 | L+0.2 | D1±0.1 | R | a |

20-39.9 | d+7.6 | 4.2 | d+1.0 | 0.4 | 3.0 |

40-69.9 | d+8.8 | 6.3 | d+1.5 | 1.0 | 3.0 |

70-139.9 | d+12.2 | 8.1 | d+2.0 | 1.2 | 4.0 |

140-399.9 | d+16.0 | 11.5 | d+2.0 | 2.0 | 5.0 |

400-649.9 | d+24.0 | 15.5 | d+2.5 | 2.5 | 8.0 |

650-999.9 | d+27.3 | 18.0 | d+2.5 | 2.5 | 10.0 |

Application and properties

For a wide range of applications, such as agricultural machinery, injection molding machines, forklifts, cranes and so on. Consisting of a sealing ring and two O-Rings for improving overall tightness, low friction, non stick slip phenomenon, good adjustment and positioning ability, high reliability, accepting the full load of work pressure in a short time.

Standard materials

Sealing ring: filled PTFE / PU

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | -36℃+200℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others | |

d f8 | D H9 | H | L+0.2 | Order No. |

20 | 27.6 | 4.0 | 4.2 | DPT1-20*27.6*4.2 |

30 | 37.6 | 4.0 | 4.2 | DPT1-30*37.6*4.2 |

36 | 43.6 | 4.0 | 4.2 | DPT1-36*43.6*4.2 |

45 | 53.8 | 6.0 | 6.3 | DPT1-45*53.8*6.3 |

56 | 64.8 | 6.0 | 6.3 | DPT1-56*64.8*6.3 |

65 | 73.8 | 6.0 | 6.3 | DPT1-65*73.8*6.3 |

80 | 92.2 | 7.7 | 8.1 | DPT1-80*92.2*8.1 |

95 | 107.2 | 7.7 | 8.1 | DPT1-95*107*8.1 |

110 | 122.2 | 7.7 | 8.1 | DPT1-110*122*8.1 |

Company Features

1. The past years has witnessed steadily gowning development of Dms Seals Technology Co.,limited for its scraper seals . DMS Seal Manufacturer is a high-tech enterprise that specializes in producing wiper seals. DMS Seal Manufacturer is a very competitive enterprise in hydraulic wiper seals industry.

2. We own our factory that covers a large floor space. The factory has a fully automated penetration rate reaching over 50% mainly thanks to the advanced automatic manufacturing facilities. We have staff that are well trained in their roles. They perform tasks far quicker and make the quality of work better, thereby increasing the productivity of the company. Our factory is well-equipped with advanced production machines that are manufactured under strict quality control. This enables us to keep on producing the best quality of products.

3. Trust DMS Seal Manufacturer and we will ensure that you gain expertise and value. Get info! DMS Seal Manufacturer provides quality service to every customer. Get info! The DMS Seal Manufacturer plan would be to eventually become an internationally famous Scraper Seals provider. Get info!

high efficiency scraper seals supplier for injection molding machines

scraper seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US