DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

GSJ-W - PTFE Hydraulic Rod Seal with NBR/FKM O-Ring

1. The production of DMS Seal Manufacturer rod seals adopts internationally advanced technology to achieve efficient and standard production.

2. rod seals is checked against customers' chosen specifications to meet a range of requirements including passing international standards of the destination market.

3. The production process of DMS Seal Manufacturer rod seals is constantly monitored by special personnel to ensure its smooth operation. So the pass rate of finished product can be ensured.

4. DMS Seal Manufacturer rod seals is strictly manufactured in line with the production procedure.

5. DMS Seal Manufacturer hydraulic rod seals is made of high-quality materials which are strictly selected by our experienced production team based on the application requirements and the industry quality standards.

6. The product has the advantage of water repellency. Its seam sealing and coating create a barrier to block the water.

7. The product features great compatibility. The materials used would not easily react with biological tissues, cells, and body fluids.

8. The product is very durable. Its roof is made of high composite material, which does not cause obvious wrinkles and breakage when repeatedly folded and stretched.

9. The product features both soft cushioning for foot protection and firmer cushioning for propulsion. The materials used in the forefoot and rearfoot part vary for different protection functions.

10. The product is of high quality. It has the perfect craftsmanship of the hardware, inner lining, the seams, and the stitching.

11. These features have help it won customer's high praise.

12. The product has achieved a high level of client satisfaction because it is highly cost-effective and is thought to be used more widely in the market.

13. The product is popular in the market due to a broad marketing channel.

14. This product has a long-standing reputation for its remarkable features.

15. The product is extensively demanded in the market due to unsurpassable advantages.

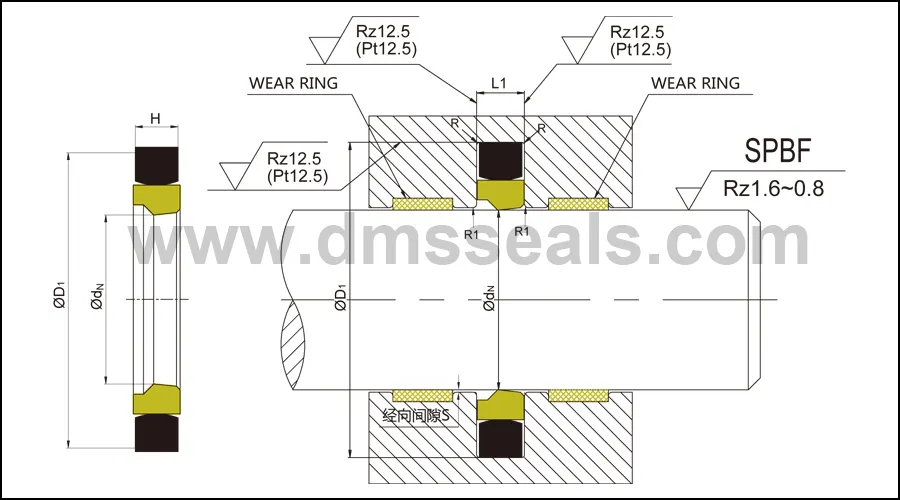

1. Installation Recommendation

2. Installation Sizes

Rod Diameter | Outer Diameter | Groove Width | Install Chamfer | Radius | Radial Clearance S max. | ||

d f8 | D H8 | L+0.2 | L1 | R1 | 10MPa | 20MPa | 40MPa |

50-69.9 | d+15.0 | 7.5 | 5.0 | 0.4 | 0.5 | 0.4 | 0.3 |

70-149.9 | d+20.0 | 10.1 | 6.0 | 0.4 | 0.7 | 0.5 | 0.4 |

200-244.9 | d+25.0 | 12.5 | 8.5 | 0.4 | 0.8 | 0.6 | 0.5 |

245-519.9 | d+30.0 | 15.0 | 10.0 | 0.8 | 0.9 | 0.7 | 0.6 |

520-769.9 | d+35.0 | 17.5 | 13.0 | 1.2 | 1.0 | 0.8 | 0.7 |

770-1500 | d+40.0 | 20.0 | 15.0 | 1.2 | 1.0 | 0.8 | 0.7 |

3. Application and properties

Applied for larger diameter piston rods and heavy-duty hydraulic rod sealing system in hard working conditions. High pressure resistance, excellent resistance to gap extrusion, wear-resisting.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -30℃ +100℃ | 5 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Outer Dia. | Groove Width | Order No. | |

d f8 | D H8 | L+0.2 | |

50 60 70 | 65 75 85 | 7.5 7.5 7.5 | GSJ-W50*65*7.5 GSJ-W60*75*7.5 GSJ-W70*85*7.5 |

75 80 100 | 95 100 120 | 10 10 10 | GSJ-W75*95*10 GSJ-W80*100*10 GSJ-W100*120*10 |

110 115 120 | 130 135 140 | 10 10 10 | GSJ-W110*130*10 GSJ-W115*135*10 GSJ-W120*140*10 |

130 140 145 | 150 160 165 | 10 10 10 | GSJ-W130*150*10 GSJ-W140*160*10 GSJ-W145*165*10 |

150 160 170 | 170 180 190 | 10 10 10 | GSJ-W150*170*10 GSJ-W160*180*10 GSJ-W170*190*10 |

175 180 200 | 195 200 220 | 10 10 10 | GSJ-W175*195*10 GSJ-W180*200*10 GSJ-W200*220*10 |

230 240 250 | 255 265 275 | 12.5 12.5 12.5 | GSJ-W230*255*12.5 GSJ-W240*265*12.5 GSJ-W250*275*12.5 |

260 265 270 | 285 290 295 | 12.5 12.5 12.5 | GSJ-W260*285*12.5 GSJ-W265*290*12.5 GSJ-W270*295*12.5 |

280 290 300 | 305 315 325 | 12.5 12.5 12.5 | GSJ-W280*305*12.5 GSJ-W290*315*12.5 GSJ-W300*325*12.5 |

Company Features

1. Engaged in manufacturing rod seals , Dms Seals Technology Co.,limited wins customers by superior quality and low price. Dms Seals Technology Co.,limited has gained high popularity for its high quality O Ring Manufacturers . Focusing on R&D and production of hydraulic rod seals , Dms Seals Technology Co.,limited is one of the most popular exporters.

2. We have set up with a complete ISO 9001 quality management system. This system is under the supervision of the Certification and Accreditation Administration of the People’s Republic of China (CNAT). The system offers a guarantee for the products we produce. We have received many honors during our business operation. We have been awarded as 'Best Supplier', 'Best Quality Provider', etc. These honors encourage us to reach better results. We have a team of experienced professionals. With years of research, they are knowledgeable about industry trends and the critical issues impacting the manufacturing industry. Our factory possesses cutting edge production technology and facilities that are introduced from developed countries. This advantage helps the factory cut waste and enhances overall production capacity.

3. Providing the best professional service for customers is the eternal mission of DMS Seal Manufacturer. Inquire! With the growing growth of o-ring seal industry, hydraulic rod seals plays an important role in the development of DMS Seal Manufacturer. Inquire! Being innovative is the source of keeping DMS Seal Manufacturer of vitality in the market. Inquire! DMS Seal Manufacturer aims to create a best atmosphere to achieve the best value for each person. Inquire!

GSJ-W - PTFE Hydraulic Rod Seal with NBR/FKM O-Ring

rod seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US