DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

gsf hydraulic piston seals with ptfe nbr and pom for pneumatic equipment

- Dms Seals is committed to providing customers with excellent, advanced and professional services. In this way can we improve their trust and satisfaction with our company.

1. The quality of DMS Seal Manufacturer pneumatic piston seals is ensured absolutely correct. Our quality control team spare no efforts on every step, material production, assembly, quality inspection and packaging to get this result.

2. DMS Seal Manufacturer pneumatic piston seals goes through rigorous inspections and quality controls to ensure quality. From raw materials to finished goods, our inspection team eliminates defects and non-compliance during different stages of the production process.

3. Before DMS Seal Manufacturer pneumatic piston seals leaves a warehouse, every aspect will be analyzed and inspected to make sure that the product is perfect in every way.

4. Our hydraulic piston seals can be in high productivity all round the clock.

5. With all its features like pneumatic piston seals , hydraulic piston seals is conducive to popularization and application.

6. The testing of the product achieves product superiority.

7. The strict quality inspection during the production efficiently prevents product defects.

8. The product has an extended service life to deliver an enduring performance.

9. Dms Seals Technology Co.,limited has an efficient sales network.

10. After receiving deposit, Dms Seals Technology Co.,limited will make production plan immediately.

11. Providing the best quality hydraulic piston seals is the purposes of Dms Seals Technology Co.,limited's service.

12. Dms Seals Technology Co.,limited has super product innovation, strong R & D strength and strict quality management awareness.

13. Dms Seals Technology Co.,limited's experienced engineers are ready to provide you with pre-sales post-sales technical support.

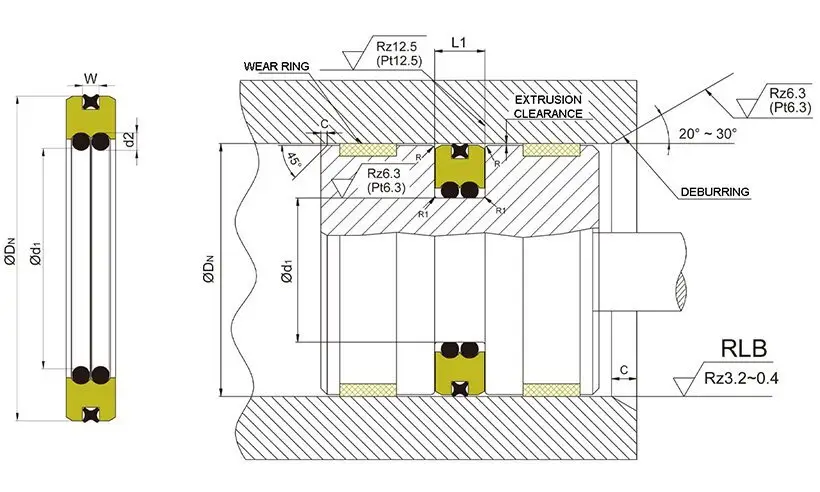

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

40 - 79.9 | 25 - 140 | DN - 10.0 | 6.3 | 0.6 | 0.3 | 0.2 | 0.15 | 2.62 | 1.78 |

80 - 132.9 | 50 - 250 | DN - 13.0 | 8.3 | 1.0 | 0.4 | 0.3 | 0.15 | 3.53 | 2.62 |

133 - 252.9 | 100 - 480 | DN - 18.0 | 12.3 | 1.3 | 0.4 | 0.3 | 0.20 | 5.33 | 3.53 |

463 - 700 | 425 - 700 | DN - 31.0 | 16.3 | 1.8 | 0.5 | 0.4 | 0.30 | 7.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Available for piston accumulator, clamping cylinder and positioning cylinder, especially recommended for heavy duty and large diameter applications. Double safety with low friction and high elasticity, Low gas permeability, excellent sliding performance in high pressure applications, no crawling phenomenon, simple groove structure, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -30℃+200℃ | 3 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

40 | 30 | 6.3 | DAQ2-40*30*6.3 | 29.82*2.62 |

48 | 38 | 6.3 | DAQ2-48*38*6.3 | 37.77*2.62 |

55 | 45 | 6.3 | DAQ2-55*45*6.3 | 44.12*2.62 |

65 | 55 | 6.3 | DAQ2-65*55*6.3 | 53.64*2.62 |

80 | 67 | 8.3 | DAQ2-80*67*8.3 | 66.27*3.53 |

95 | 82 | 8.3 | DAQ2-95*82*8.3 | 78.97*3.53 |

110 | 97 | 8.3 | DAQ2-110*97*8.3 | 94.84*3.53 |

125 | 112 | 8.3 | DAQ2-125*112*8.3 | 110.72*3.53 |

140 | 122 | 12.3 | DAQ2-140*122*12.3 | 120.02*5.33 |

Company Features

1. Dms Seals Technology Co.,limited is a leading global manufacturer and marketer of premium branded hydraulic piston seals . Being skilled at offering the most considerate service, DMS Seal Manufacturer also has the ability to manufacture piston seals . DMS Seal Manufacturer now has a deeply profound influence on the o-ring seal market.

2. DMS Seal Manufacturer has the capability to produce hydraulic piston seals with pneumatic piston seals . Our good quality hydraulic piston seals is made by hydraulic piston seals . Dms Seals Technology Co.,limited has potent capabilities both in hydraulic piston seals R&D and production. Due to the advanced and independent technology, DMS Seal Manufacturer develops finest hydraulic piston seals .

3. To provide best service for customers, Dms Seals Technology Co.,limited will collect needs of customers. Inquire now! Taking hydraulic piston seals as its mission will lead DMS Seal Manufacturer to its right way. Inquire now! DMS Seal Manufacturer is committed to working with customers to achieve a win-win situation. Inquire now! Implementing the strategy of strengthening hydraulic piston seals is a requirement for the sustainable and healthy development of DMS Seal Manufacturer. Inquire now!

gsf hydraulic piston seals with ptfe nbr and pom for pneumatic equipment

hydraulic piston seals

Type:gsf

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US