DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seals mechanical shaft seals springs wholesale

Temperature Range:

-55℃ +225℃

Medium:

hydraulic oil, fire retardant liquid, water, gas

Company Advantages

1. The necessary tests have been conducted on DMS Seals . These tests include tear strength testing, durability testing, structural stability testing, and slip resistance testing. Quality control of the seals is the basis for DMS Seals

2. The product is highly demanded in the market for wide applications. Seal we produced has applications in a wide range of fields

3. This product is waterproof. A specifically manufactured chemical is coated onto its exterior shell or infused with the fibers of its fabric to repel water. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

4. The product has stable performance under extreme weathers. It does not prone to affect by thundering and lightning, storms, or humid weather. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

5. It presents good color accuracy. Its surface has a proper gain, which helps to bring out more vivid blacks and enhance a projector's native contrast ratio. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

Company Features

1. We have experienced technical designers and manufacturing engineers. They can work with customers in optimizing product design, bringing the concept to an often under-budget realization.

2. We will do our best to meet the needs of our customers on . Check it!

1. The necessary tests have been conducted on DMS Seals . These tests include tear strength testing, durability testing, structural stability testing, and slip resistance testing. Quality control of the seals is the basis for DMS Seals

2. The product is highly demanded in the market for wide applications. Seal we produced has applications in a wide range of fields

3. This product is waterproof. A specifically manufactured chemical is coated onto its exterior shell or infused with the fibers of its fabric to repel water. DMS O Ring Manufacturers strictly follows the ISO9001 international quality certification system for production management

4. The product has stable performance under extreme weathers. It does not prone to affect by thundering and lightning, storms, or humid weather. The R&D teams have the ability to design and develop seals for various of complicated working condition of sealing system

5. It presents good color accuracy. Its surface has a proper gain, which helps to bring out more vivid blacks and enhance a projector's native contrast ratio. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

Product Description

bg

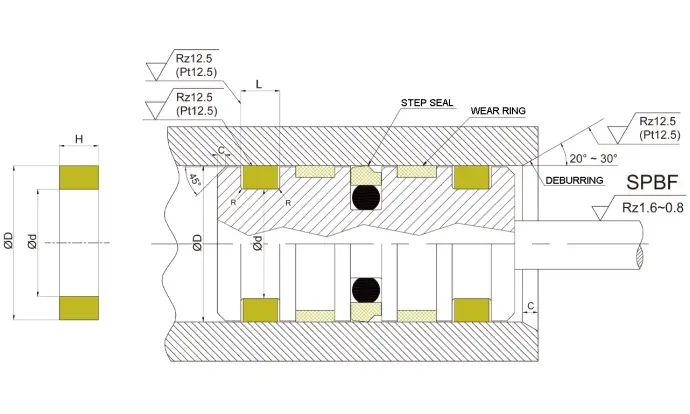

Dust rings are used in conjunction with piston seals and wear rings, it could prevent the impurities to damage the sealing elements in the cylinder,to ensure the longer life of the sealing element. When used in conjunction with piston rod seals and metal bushings, it could protect the damage for the piston rods.There is an incision and an oil pressure bypass slot to prevent the accumulation of oil pressure.

| Item | Specifications |

| Product Name | Kzt Anti-Pollution Seal Dust Seal Anti-Fouling and Anti-Wear Ring |

| Products Category | Hydraulic seals, Oil seals, O-Rings |

| Material | PTFE, PU, NBR, FKM, PA, POM, Silicone, EPDM, FFKM, UPE, PEEK etc. |

| Propeties | High temperature, low temperature, high pressure, low pressure,friction resistance |

| Sizes | Standard and customize |

| Medium | Hydraulic oil, anti-fire fluid, water, gas etc |

| Application | excavators, loaders, graders, dump trucks, forklifts, bulldozers, scrapers, mining trucks, cranes, aerial vehicles, garbage transfer vehicle, sliding cars, agricultural machinery, logging equipment, etc. |

Product Parameters

bg

| NO. | SIZE | NO. | SIZE | NO. | SIZE |

| 1 | KZT70*62*4 | 24 | KZT190*182*6 | 47 | KZT130*122*9.5 |

| 2 | KZT75*67*4 | 25 | KZT100*92*7.9 | 48 | KZT135*127*9.5 |

| 3 | KZT80*72*4 | 26 | KZT105*97*7.9 | 49 | KZT140*132*9.5 |

| 4 | KZT85*77*4 | 27 | KZT110*102*7.9 | 50 | KZT145*137*9.5 |

| 5 | KZT90*82*4 | 28 | KZT115*107*7.9 | 51 | KZT150*142*9.5 |

| 6 | KZT80*72*6 | 29 | KZT120*112*7.9 | 52 | KZT160*152*9.5 |

| 7 | KZT85*77*6 | 30 | KZT125*117*7.9 | 53 | KZT170*162*9.5 |

| 8 | KZT90*82*6 | 31 | KZT130*122*7.9 | 54 | KZT180*172*9.5 |

| 9 | KZT95*87*6 | 32 | KZT135*127*7.9 | 55 | KZT190*182*9.5 |

| 10 | KZT100*92*6 | 33 | KZT140*132*7.9 | 56 | KZT200*192*9.5 |

| 11 | KZT105*97*6 | 34 | KZT145*137*7.9 | 57 | KZT90*82*14.8 |

| 12 | KZT110*102*6 | 35 | KZT150*142*7.9 | 58 | KZT95*87*14.8 |

| 13 | KZT115*107*6 | 36 | KZT160*152*7.9 | 59 | KZT100*92*14.8 |

| 14 | KZT120*112*6 | 37 | KZT170*162*7.9 | 60 | KZT105*97*14.8 |

| 15 | KZT125*117*6 | 38 | KZT180*172*7.9 | 61 | KZT110*102*14.8 |

| 16 | KZT130*122*6 | 39 | KZT190*182*7.9 | 62 | KZT115*107*14.8 |

| 17 | KZT135*127*6 | 40 | KZT200*192*7.9 | 63 | KZT120*112*14.8 |

| 18 | KZT140*132*6 | 41 | KZT100*92*9.5 | 64 | KZT125*117*14.8 |

| 19 | KZT145*137*6 | 42 | KZT105*97*9.5 | 65 | KZT130*122*14.8 |

| 20 | KZT150*142*6 | 43 | KZT110*102*9.5 | 66 | KZT135*127*14.8 |

| 21 | KZT160*152*6 | 44 | KZT115*107*9.5 | 67 | KZT140*132*14.8 |

| 22 | KZT170*162*6 | 45 | KZT120*112*9.5 | 68 | KZT145*137*14.8 |

| 23 | KZT180*172*6 | 46 | KZT125*117*9.5 | 69 | KZT150*142*14.8 |

Company Features

1. We have experienced technical designers and manufacturing engineers. They can work with customers in optimizing product design, bringing the concept to an often under-budget realization.

2. We will do our best to meet the needs of our customers on . Check it!

{{item.score}} Stars

{{item.pre}}%

{{item.nickname ? (item.nickname.slice(0, 2) + '*****') : item.source === 1 ? 'mall buyer' : '--'}}

{{item.comment_time}}

Review in the {{item.country}}

{{itemAttr.params_key}}: {{itemAttr.params_value}}

Contact us

we welcome custom designs and ideas and is able to cater to the specific requirements. for more information, please visit the website or contact us directly with questions or inquiries.

you might like

no data

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US