DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer virgin bearing element high end for sale

- Dms Seals carries out the service model of 'standardized system management, closed-loop quality monitoring, seamless link response, and personalized service' to provide comprehensive and all-around services for consumers.

1. DMS Seal Manufacturer rubber seal design is produced in a standard production environment.

2. The production process of DMS Seal Manufacturer rubber seal design is supported by advanced technology.

3. With the assistance of a team of innovative and experienced designers, DMS Seal Manufacturer bearing element is given a wide variety of design styles.

4. An internal team or a third-party team is hired to determine whether the product meets the standards.

5. This product offers exemplary performance without compromising quality.

6. Even in extreme condition, our bearing element can work normally.

7. Its first-class performance is loved by global customers.

8. The principle rubber seal design of Dms Seals Technology Co.,limited has an important instructive function to develop bearing element with oil seal ring .

9. Dms Seals Technology Co.,limited has tried our best to be the industry leader and innovator in bearing element .

10. Dms Seals Technology Co.,limited is a professional manufacturer and exporter that is concerned with the design,development and production of rubber seal design and oil seal ring .

11. Apart from our high quality bearing element , we are highly recognized for our transparent deals and on time delivery of products.

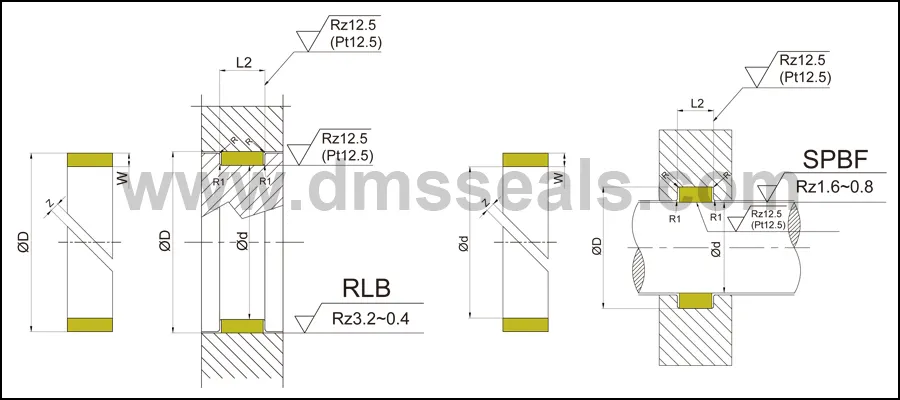

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

White virgin PTFE

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | — | -55℃ +225℃ | 15 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Length of whole roll

Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 5 | 6 |

Length of whole roll ( m ) | 55 | 35 | 27 | 22 | 18 | 13 | 10 | 8 |

Above data only for reference, it shall follow the actual products.

Standard groove width

Groove width L2 | 2.5 | 3.2 | 4 | 4.2 | 5.6 | 6 | 6.3 | 8.1 | 9.7 | 10 | 12 | 15 | 18 | 20 | 25 | 30 | 40 | 50 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 1 | 1.5 | 1.55 | 2 | 2.5 | 3 | 4 | 5 | 6 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited works with famous brands with resource advantages. As a leading bearing element industry company, DMS Seal Manufacturer is very proud. Dms Seals Technology Co.,limited has always been an industry leader in the fierce competition.

2. Dms Seals Technology Co.,limited is to set up a oil seal manufacturer producing park and develop an industrial chain. Designated as a national fixed-point bearing element units, Dms Seals Technology Co.,limited has a strong technological base and manufacturing capacity. The advanced mechanical processing equipment is available in Dms Seals Technology Co.,limited's manufacturing plant.

3. To provide the highest quality bearing element is our persistent mission to satisfy the customers and achieve the value of ourselves. Get info! Based on the tenet of rubber seal design , DMS Seal Manufacturer strives hard to achieve the goal of oil seal ring . Get info! All DMS Seal Manufacturer staff keeps our clients in mind and does the utmost to satisfy customers. Get info! To carry forward rubber o rings manufacturers is the base of Dms Seals Technology Co.,limited's work. Dms Seals Technology Co.,limited promotes entrepreneurship and dare to take risks during the development. Get info!

DMS Seal Manufacturer virgin bearing element high end for sale

bearing element

Type:high end 、 Type1:dfi

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US