DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer Suppliers for aviation

-

v s

1. Innovation-oriented design: DMS Seal Manufacturer is innovatively designed by a team of professional designers. They are full of innovative ideas and are willing to embrace the changing market demands.

2. DMS Seal Manufacturer is manufactured as per the current industry standards.

3. DMS Seal Manufacturer is manufactured under the guidance of our experienced professionals, using advanced machines and tools in tandem with international quality standards.

4. The raw materials of DMS Seal Manufacturer is carefully chosen from top grade suppliers.

5. DMS Seal Manufacturer is developed with an efficient production process. The production time of each product is greatly optimized and the loss and waste of raw materials are effectively reduced.

6. The strong point of is .

7. Dms Seals Technology Co.,limited's have strong competitive advantages in terms of technology and quality.

8. Because of favorable compatibility, is more and more popular in the field.

9. Compared with existing technologies, the has advantages of .

10. Dms Seals Technology Co.,limited has the most knowledgeable experts and reliable, easy-to-use products.

11. Mature sales network of DMS Seal Manufacturer will bring more convenience for customers.

12. Dms Seals Technology Co.,limited is able to provide customers around the world with internationally-advanced technology and support.

13. The strict quality standards make Dms Seals Technology Co.,limited's worldwide export possible.

14. Dms Seals Technology Co.,limited has a reputation for excellent service and the nice .

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

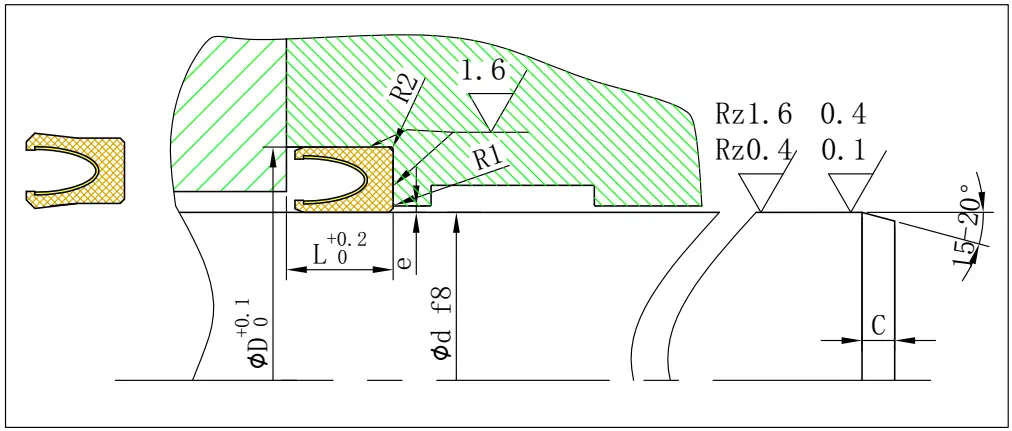

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Dms Seals Technology Co.,limited is a highly-recognized manufacturer and supplier of . We specialize in the R&D, design, and production. Having extensive experience in designing and developing , Dms Seals Technology Co.,limited is known as one of the leading manufacturers in China. Dms Seals Technology Co.,limited has been focusing on the production of . Professional developing and manufacturing abilities make us a trustworthy supplier.

2. Dms Seals Technology Co.,limited has highly experienced R&D team. DMS Seal Manufacturer has advanced technical equipment to improve the quality of . To stand out in the highly competitive industry, DMS Seal Manufacturer has successfully established its own development technology. DMS Seal Manufacturer devotes to concentrate on the technical innovation and optimization. Besides the professionals, the progressive technology is also critical to the production of rotary seals catalogue .

3. DMS Seal Manufacturer hopes to bring customers with best user experience for mse seal . Ask online! Customer's satisfaction is what Dms Seals Technology Co.,limited will always cling to. Ask online! Guaranteed innovative capabilities plays an important role in driving DMS Seal Manufacturer to be a leading brand in the market. Ask online! Dms Seals Technology Co.,limited looks forward to partnering with more clients from the world with its high quality spring loaded oil seal . Ask online!

DMS Seal Manufacturer Suppliers for aviation

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US