DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer spring seals solutions for reciprocating piston rod or piston single acting seal

1. DMS Seal Manufacturer spring loaded seal is manufactured under the guidance of our experienced professionals, using advanced machines and tools in tandem with international quality standards.

2. DMS Seal Manufacturer spring loaded seal is made from the best quality raw materials that assure customers of our authenticity.

3. DMS Seal Manufacturer spring loaded seal is manufactured utilizing the precision machining equipment.

4. DMS Seal Manufacturer spring seals is developed and manufactured using the latest technology materials.

5. We are committed to research and development of new technology, so that our product quality and performance is in the forefront of the industry.

6. This product has been tested for good performance and durability.

7. The product has received many international certifications, which is a strong proof of its high quality and high performance.

8. This product is internationally renowned for its superior performance and long life.

9. The service of DMS Seal Manufacturer helps promote the popularity of the company.

10. The strength of the staff team in Dms Seals Technology Co.,limited is continuously strengthened.

11. DMS Seal Manufacturer believes that the best way to provide services is to send services to customers.

12. Dms Seals Technology Co.,limited is dedicated to serving customers with its experienced management team.

1. Application and properties

Suitable for reciprocating piston rod or piston single acting seal, the working pressure has a wide range of adaptability, and the pressure capacity can be enhanced by increasing the tail length size or increasing the check ring.

Small friction coefficient, The contact pressure between the mating surface and the mating surface is low, and the friction between the work face and the mating surface is the smallest in all seal types. with or without lubrication can work, wear resistance, long service life.

The working medium of the sealing sleeve has wide adaptability, and the other chemicals are not reacted except soluble alkali metal, high temperature fluorine gas and three fluoride chloride.

The working temperature range is wide, and can be used for -200 ℃ to +250 ℃.

It can be used for very high speed, very low speed, micro-stroke and other special conditions.

Suitable for aviation, military and industrial sealing groove size, The standard installation groove is the same size as the standard O ring, and the size is small. It can be designed as non standard parts to meet the sealing requirements of any size groove. The groove is open or semi open.

It can be used in rotary sealing. It can adapt to large eccentricity and beating.

2. Standard materials

Sealing sleeve: PTFE

Spring: Stainless steel 304, 316

3. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range ℃ | Speed | Medium |

3 - 1600mm | 0 - 20MPa | -200 ~ +250 | 5 m/s | High and low temperature oil and water and other fluids. |

4. Installation Sizes

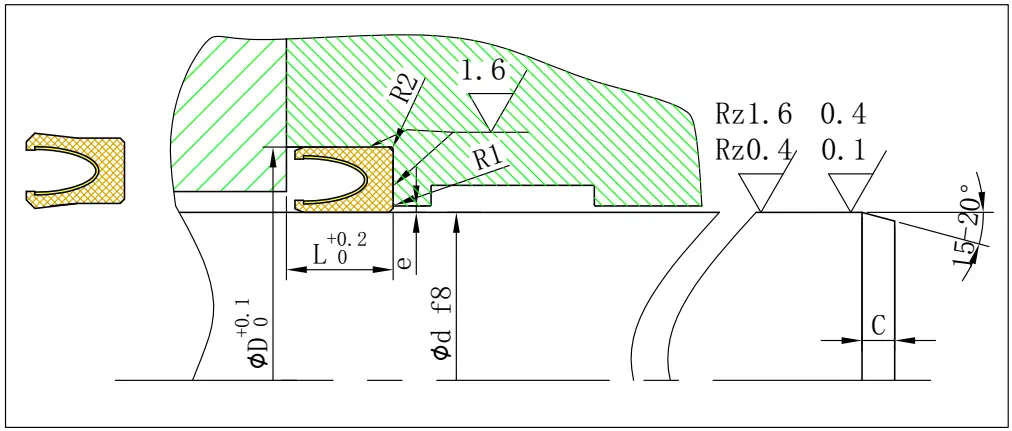

Back pressure surfaceR1=0.1 ~ 0.2, tank bottom R2=0.3 ~ 0.5, Import lengthC=(0.7 ~ 1.0)L.

Rod Diameter

| Groove Width | Groove Diameter | Radial Clearance

|

d | L | D | e |

2 ~ 10 | 2.5 | d+3.0 | 0.05 |

10 ~ 22 | 3.2 | d+4.0 | 0.065 |

22 ~ 52 | 4.7 | d+6.0 | 0.075 |

48 ~ 150 | 7.5 | d+10.0 | 0.09 |

150 ~ 400 | 11.0 | d+15.0 | 0.10 |

5. Matters needing attention

Ⅰ, The installation groove must be open or semi open, and it is recommended to be open.

Ⅱ, If the seal is for the rotating shaft, it is recommended that the surface hardness of the shaft should be no less than HRC40.

Ⅲ,Considering the adaptability of the working medium, the adaptability of the jacket and spring should be taken into account.

Ⅳ, It is better to install an anti fouling ring or a antifouling guide ring in the notch direction in front of the seal.

Company Features

1. Praised as a highly professional manufacturer of spring seals , Dms Seals Technology Co.,limited has been engaged in this industry for years. Since the founding, Dms Seals Technology Co.,limited has developed and manufactured high-quality and innovative spring loaded seal that sets us apart from the competition. After years of engagement in manufacturing oil seal manufacturer, Dms Seals Technology Co.,limited has been a well-positioned and reliable manufacturer with years of experience.

2. We are powered by a team of manufacturing experts. They have accumulated years of experience and are working hard to push China manufacturing by providing the highest level of products. We have an in-house design team. They work closely with our fabrication teams to ensure each and every item they design meets our strict QC standards. We have brought together a production team. They are equipped with decades of experience. With their wide range of engineering and manufacturing capabilities, they can produce the exact products that customers require. Over the years, we have strengthened our in-house sales and marketing divisions and started selling our products to customers and organizations in the global market. We have set up with a complete ISO 9001 quality management system. This system is under the supervision of the Certification and Accreditation Administration of the People’s Republic of China (CNAT). The system offers a guarantee for the products we produce.

3. With a commitment to continuous sustainability, we work hard to utilize the natural resources we consume including raw materials, energy, and water as efficiently as possible. Improving customers' satisfaction is what we always pursue. We will require employees to take part in customer service training, so as to strengthen their empathy and a better understanding of customers' needs. We are marching forwards a more environmental-friendly and greener production way. We promise to eliminate any practices that will harm society and our environment. For example, during production, the waste will be carefully handled by our QC team.

DMS Seal Manufacturer spring seals solutions for reciprocating piston rod or piston single acting seal

spring seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US