DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer rubber piston seals for light and medium hydraulic systems

1. DMS Seal Manufacturer is exclusively developed by the in-house R&D members to accommodate with Windows and Mac computers. Thus, information can be saved and stored in the above systems.

2. Developed by a professional R&D team, DMS Seal Manufacturer has ultra-sensitive and responsive surface. The team always strive to improve its screen touch technology so as to provide better writing and drawing experience.

3. DMS Seal Manufacturer is produced under standardized and scientific lighting standards. For example, the selection process of the light source highly meet the international lighting standards.

4. This product is naturally dust mite resistant and anti-microbial, which prevents the growth of mold and mildew, and it's also hypoallergenic and resistant to dust mites.

5. The stable and reliable chemical and physical properties of this product are the outcomes of its internal structure which is uniquely formed.

6. The product is resistant to corrosion. The materials used have been treated to resist the impact of chemical acids, strong cleaning fluids or hydrochloric compounds.

7. In addition to providing better protection for goods, it is always the focus of customers. That's why people need to use this product for their commodity.

8. This product is aesthetically pleasing to the eye, which will conjure up the romance and beauty of a special event.

9. One benefit is that there are so many accessories that one can have with this product such as container padlocks and container lockboxes (which add additional security), container lighting, container ramps, moisture traps, etc.

10. The product greatly cut down employee costs. It only needs a few people to support its operation, thus the labor costs can be saved.

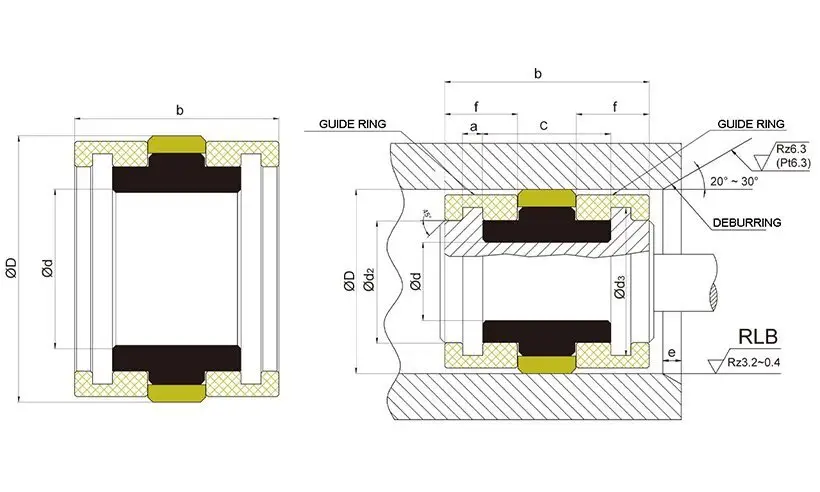

Application and properties

Apply to cylinder piston,Consisting of a seal ring, an O-Ring, a pair of retaining rings and a pair of guide sleeves. The seal ring and cylinder bore conforming to be a symmetric section to achieve the sealing performance, with double acting sealing performance.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

Guide ring: filled PTFE / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1 m/s | hydraulic oil, water and emulsion |

D | d | b | d2 | d3 | a | c | f | e | Order No. |

40 | 26 | 30 | 32 | 36 | 3.5 | 15.5 | 7.25 | 7 | DKDF40*26*30 |

56 | 40 | 32 | 48 | 52 | 3 | 20.5 | 5.8 | 7 | DKDF56*40*32 |

65 | 49 | 32 | 57 | 61 | 3 | 20.5 | 5.8 | 7 | DKDF65*49*32 |

80 | 62 | 36 | 72 | 76 | 3 | 22.5 | 6.8 | 7 | DKDF80*62*36 |

95 | 77 | 36 | 87 | 91 | 3 | 22.5 | 6.8 | 7 | DKDF95*77*36 |

110 | 92 | 36 | 102 | 106 | 3 | 22.5 | 6.8 | 10 | DKDF110*92*36 |

125 | 103 | 43 | 115 | 121 | 4 | 26.5 | 8.3 | 10 | DKDF125*103*43 |

140 | 118 | 43 | 130 | 136 | 4 | 26.5 | 8.3 | 10 | DKDF140*118*43 |

155 | 133 | 43 | 145 | 151 | 4 | 26.5 | 8.3 | 10 | DKDF155*133*43 |

180 | 158 | 48 | 170 | 176 | 6 | 26.5 | 10.8 | 10 | DKDF180*158*48 |

200 | 175 | 48 | 190 | 196 | 4.5 | 31.5 | 8.3 | 10 | DKDF200*175*48 |

235 | 210 |

| 225 | 231 | 15 | 31.5 | 21.3 | 12 | DKDF235*210*74 |

265 | 240 | 74 | 255 | 261 | 15 | 31.5 | 21.3 | 12 | DKDF265*240*74 |

Company Features

1. Dms Seals Technology Co.,limited is positioned as a leading manufacturer of rubber piston seals. After successfully introducing high technologies, DMS Seal Manufacturer has been more confident to create high quality hydraulic piston seals sizes . Dms Seals Technology Co.,limited has developed into an international leader in the field of hydraulic piston seals . Dms Seals Technology Co.,limited has developed rapidly and is a leader in the world o-ring seal market. With premium excellent service, Dms Seals Technology Co.,limited has a high reliability in the market.

2. The employees are our greatest strength. In the face of today's challenges, their skills and commitment are the energy that drives the company forward in every corner of the world. With a modern production line, Dms Seals Technology Co.,limited has the ability to fully produce high quality pneumatic piston seals . Our factory keeps pace with the advanced technologies in this industry. We introduce the domestic and foreign advanced production technologies into our production lines and these technologies have proved that they can greatly promote productivity and higher quality products. The DMS Seal Manufacturer factory uses advanced production equipment and testing equipment. Our CEO is responsible for the strategic development of our business. He/She continues to expand the development and production of products and improve manufacturing services through the penetration of new markets.

3. We stick to the highest standard of behavior and ethics - we treat our customers and suppliers with fairness, honesty, and respect. We are heading towards to become a truly sustainable enterprise. We will significantly reduce the negative impact on the environment, such as reducing wastes discharge and carbon footprint. We never stop assuming social responsibility. We care about the development of communities and society, and we donate capitals to help build charity houses and hospitals. To keep with our longstanding commitment to Green quality standards, we maintain the highest international quality standards in our products, production processes, customer service, and manpower. In order to deliver better, we always hold fast to the company values of integrity, respect for people, customer enthusiasm, excellence, and vitality.

DMS Seal Manufacturer rubber piston seals for light and medium hydraulic systems

rubber piston seals

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US