DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer rubber gasket design guide for business for injection molding machines

1. The quality DMS Seal Manufacturer is produced with excellent workmanship and finishing.

2. rubber gasket design guide is more cost-effective and environment friendly.

3. To enhance the competitiveness, DMS Seal Manufacturer also pays attention to the design of rubber gasket design guide .

4. DMS Seal Manufacturer is manufactured with 5S standard production process.

5. The design concept of rubber gasket design guide is based on modern green style.

6. This product can be guaranteed with a high safety level. It has passed the materials test that focuses on the safety of ingredients.

7. It has good strength. Its materials have the required toughness to resist deformation under stress and resist fracture due to high impact load.

8. This product has good chemical resistance. Its resistance to oils, acids, bleaches, tea, coffee, etc. has been measured and verified in manufacturing.

9. This product has a best-suited shape. Its dimensions are calculated based on the loads on its elements and strength of the material.

10. Without good quality, rubber gasket design guide can't be keeping stable rise for sales volume in its market.

11. Test proved that rubber gasket design guide is .

12. The strength of Dms Seals Technology Co.,limited is to make a steady progress.

13. Dms Seals Technology Co.,limited has taken a big jump in technology and service capacity in rubber gasket design guide field.

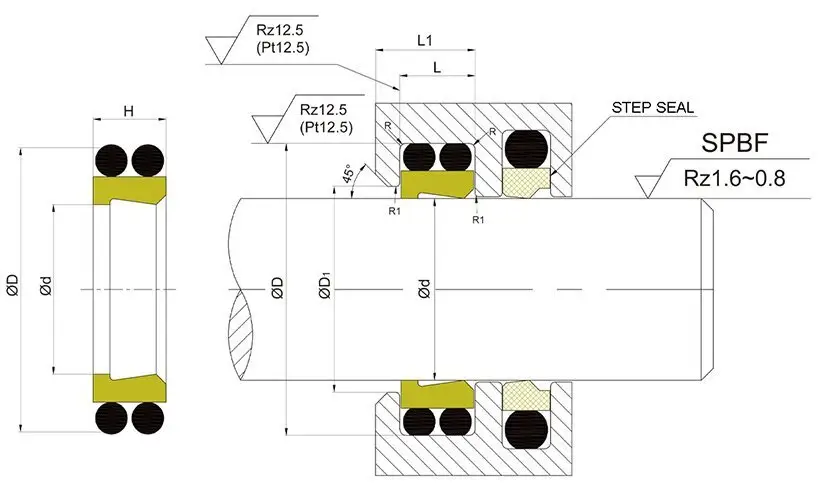

Rod Diameter | Groove Diameter | Groove Width | Bore Diameter | Radius | Step Width |

d f8/h9 | D H9 | L+0.2 | D1±0.1 | R | a |

20-39.9 | d+7.6 | 4.2 | d+1.0 | 0.4 | 3.0 |

40-69.9 | d+8.8 | 6.3 | d+1.5 | 1.0 | 3.0 |

70-139.9 | d+12.2 | 8.1 | d+2.0 | 1.2 | 4.0 |

140-399.9 | d+16.0 | 11.5 | d+2.0 | 2.0 | 5.0 |

400-649.9 | d+24.0 | 15.5 | d+2.5 | 2.5 | 8.0 |

650-999.9 | d+27.3 | 18.0 | d+2.5 | 2.5 | 10.0 |

Application and properties

For a wide range of applications, such as agricultural machinery, injection molding machines, forklifts, cranes and so on. Consisting of a sealing ring and two O-Rings for improving overall tightness, low friction, non stick slip phenomenon, good adjustment and positioning ability, high reliability, accepting the full load of work pressure in a short time.

Standard materials

Sealing ring: filled PTFE / PU

O-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | -36℃+200℃ | 5 m/s | hydraulic oil, flame retardant liquid, water and others | |

d f8 | D H9 | H | L+0.2 | Order No. |

20 | 27.6 | 4.0 | 4.2 | DPT1-20*27.6*4.2 |

30 | 37.6 | 4.0 | 4.2 | DPT1-30*37.6*4.2 |

36 | 43.6 | 4.0 | 4.2 | DPT1-36*43.6*4.2 |

45 | 53.8 | 6.0 | 6.3 | DPT1-45*53.8*6.3 |

56 | 64.8 | 6.0 | 6.3 | DPT1-56*64.8*6.3 |

65 | 73.8 | 6.0 | 6.3 | DPT1-65*73.8*6.3 |

80 | 92.2 | 7.7 | 8.1 | DPT1-80*92.2*8.1 |

95 | 107.2 | 7.7 | 8.1 | DPT1-95*107*8.1 |

110 | 122.2 | 7.7 | 8.1 | DPT1-110*122*8.1 |

Company Features

1. Dms Seals Technology Co.,limited becomes the preferred choice for most of the Chinese customers. We specialize in the production of . Dms Seals Technology Co.,limited has quickly developed into a well-known rubber gasket design guide supplier both at home and abroad. The market share of the company can be seen soaring recently. For so many years, Dms Seals Technology Co.,limited is regarded as a reliable and trustworthy manufacturer for our clients and suppliers. DMS Seal Manufacturer is a favored brand of with incomparable advantages. As a rapidly growing enterprise, Dms Seals Technology Co.,limited continuously expanding its overseas markets in recent years. Our quality enjoys more and more popularity in domestic and overseas markets.

2. Our sales networks extend to many foreign markets. They are the Middle East, Japan, America, and some Europe countries. We have maintained stable and friendly business relationships with those customers for many years. The factory is well-equipped with a full set of manufacturing facilities and testing equipment. This not only enables us to increase production efficiency, but also helps us improve the customer satisfaction level by high-quality products. Our manufacturing team consists of experienced specialists. With their years of expertise and great sensitivity, they can produce high-quality products both standard and custom.

3. Striving for the realizing the great works of is our ultimate goal. Inquiry! Dms Seals Technology Co.,limited is confident to meet the needs of customers in different industries. Inquiry! Dms Seals Technology Co.,limited clings to the business philosophy of . Inquiry! The service of DMS Seal Manufacturer is highly recommended. Inquiry! Dms Seals Technology Co.,limited aims to create an international advanced rod seal design supplier. Inquiry!

DMS Seal Manufacturer rubber gasket design guide for business for injection molding machines

rubber gasket design guide

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US