DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer rotary seals manufacturer o ring for larger piston clearance

1. During the production of DMS Seal Manufacturer , mold shaping or compression molding workmanship is adopted to guarantee its robust and stiff structure. The high pressure seals have strong wear resistance to hard conditions

2. The product helps reduce foot diseases, guaranteeing comfortable and healthy feet thanks to the combination of breathable materials. DMS Seals implements and optimizes its quality control systems

3. It is designed to focus on the core functions to show the maximum performance. Seal we produced has applications in a wide range of fields

4. Customer demand is greatly fueled by the durability and performance of the product. DMS Seal manufacturer provides good quality and competitive price hydraulic seals

1. Installation Recommendation

2. Application and properties

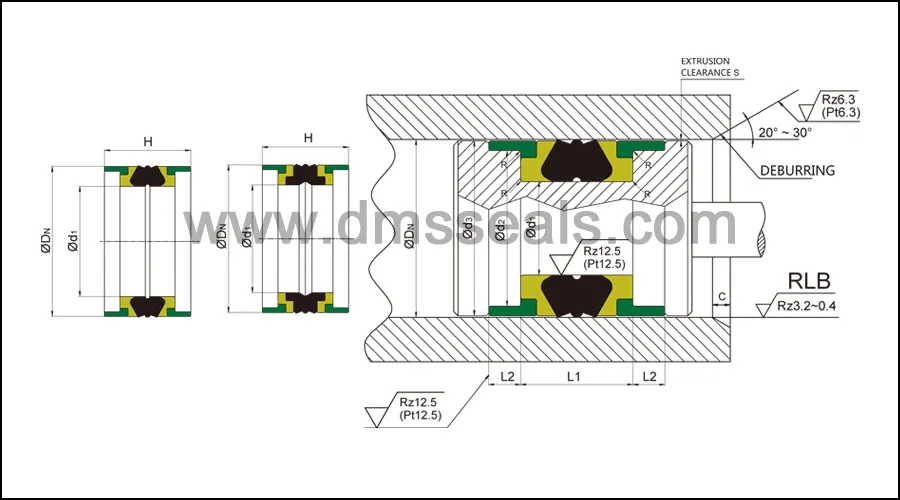

DBM/TPM is a double acting sealing and guiding element, Consisting of an elastomer, two back-up rings and two guide rings. Dynamic and static properties of the elastomer play a good sealing role, The back-up ring prevents the elastomer from being squeezed into the sealing gap, the function of the guide ring is to guide the piston in the cylinder and absorb the radial force. The sealing is mainly used for piston and hydraulic cylinder, such as bulldozers, excavators, loaders, hydraulic gates and agricultural machinery.

3. Standard materials

Guide ring: filled PTFE / PA

Back-up ring: TPU polymer

Elastomer: NBR

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-35MPa | -30℃ +120℃ | 0.5 m/s | petroleum base hydraulic oil,nonflammable hydraulic oil, environmental protection hydraulic oil |

5. Installation Dimensions

Cylinder Dia. | Groove Size | Order No. | ||||

DN H9 | d1 | L1 +0.2 | d2 h9 | d3 h11 | L2 +0.1 | |

22 25 | 11 13 15 | 13.5 13.5 12 | 17 19 21 | 19 21 23 | 2.1 2.1 4 | TPM20*11*13.5*2.1 TPM22*13*13.5*2.1 TPM25*15*12*4 |

25 25 25 | 15 15 16 | 12.5 16.4 13.5 | 22 21.45 22 | 24 23.5 24 | 4 6.35 2.1 | TPM25*15*12.5*4 TPM25*15*16.4*6.35 TPM25*16*13.5*2.1 |

28 30 30 | 19 17 21 | 13.5 15.4 13.5 | 25 26.5 27 | 27 28.5 29 | 2.1 6.35 2.1 | TPM28*19*13.5*2.1 TPM30*17*15.4*6.35 TPM30*21*13.5*2.1 |

32 35 | 22 22 25 | 15.5 16.4 15.5 | 28 28.5 31 | 31 30.5 34 | 2.6 6.35 2.6 | TPM32*22*15.5*2.6 TPM32*22*16.4*6.35 TPM35*25*15.5*2.6 |

35 40 40 | 25 24 26 | 16.4 18.4 15.5 | 31.4 35.4 36 | 33.5 38.5 39 | 6.35 6.35 2.6 | TPM35*25*16.4*6.35 TPM40*24*18.4*6.35 TPM40*26*15.5*2.6 |

40 40 40 | 30 30 30 | 12.5 12.5 16.4 | 36 37 35.4 | 38 39 38.5 | 4 4 6.35 | TPM40*30*12.5*4 TPM40*30*12.5*4 TPM40*30*16.4*6.35 |

42 45 45 | 28 29 31 | 15.5 18.4 15.5 | 38 40.4 41 | 41 43.5 44 | 2.6 6.35 2.6 | TPM42*28*15.5*2.6 TPM45*29*18.4*6.35 TPM45*31*15.5*2.6 |

45 50 50 | 35 34 34 | 16.4 18.4 20.5 | 40.4 45.4 46 | 43.5 48.5 49 | 6.35 6.35 3.1 | TPM45*35*16.4*6.35 TPM50*34*18.4*6.35 TPM50*34*20.5*3.1 |

55 55 56 | 39 39 40 | 18.4 20.5 20.5 | 50.36 51 52 | 53.5 54 55 | 6.35 3.1 3.1 | TPM55*39*18.4*6.35 TPM55*39*20.5*3.1 TPM56*40*20.5*3.1 |

60 60 63 | 44 44 47 | 18.4 20.5 18.4 | 55.4 56 58.4 | 58.5 59 61.5 | 6.35 3.1 6.35 | TPM60*44*18.4*6.35 TPM60*44*20.5*3.1 TPM63*47*18.4*6.35 |

63 63 65 | 47 47 49 | 19.4 20.5 20.5 | 58.4 59 61 | 61.5 62 64 | 6.35 3.1 3.1 | TPM63*47*19.4*6.35 TPM63*47*20.5*3.1 TPM65*49*20.5*3.1 |

65 70 70 | 50 50 54 | 18.4 22.4 20.5 | 60.4 64.2 66 | 63.5 68.3 69 | 6.35 6.35 3.1 | TPM65*50*18.4*6.35 TPM70*50*22.4*6.35 TPM70*54*20.5*3.1 |

Company Features

1. DMS Seal Manufacturer is a company integrating developing, designing, sales and service of rotary seals manufacturer .

2. Our friendly project management team has a wealth of experience and knowledge of the industries. They are familiar with culture and language in the target market. They can provide expert advice throughout the order process.

3. Customers' trust is DMS Seal Manufacturer's driving force for excellence. Call!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US