DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer roller bearing co for business as the guide sleeve

-

v s

1. roller bearing co adopts the structure of and exhibits such features like .

2. roller bearing co from Dms Seals Technology Co.,limited mainly uses high-end materials.

3. The sophisticated design of roller bearing co allows for .

4. The product is featured by excellent performance and reliable quality.

5. The product is of reliable quality and can be used for a long time.

6. The product combines versatility with excellent performance.

7. This product ultimately promotes increased efficiency and cost savings for manufacturers. This is why it is commonly used in many applications.

8. I like the tailoring of this product. I've used it several times and will continue to use it, said one of our customers.

9. The product is an excellent tool to take the stress out of everyday fatigue. It improves overall production efficiency and simplifies operation tasks.

10. This product will bring higher sales. It will help the company to establish a professional image of its goods and therefore promote sales.

11. Eye-catching lines and elegant curves are just two of the most striking features that people will notice the first time they see this product.

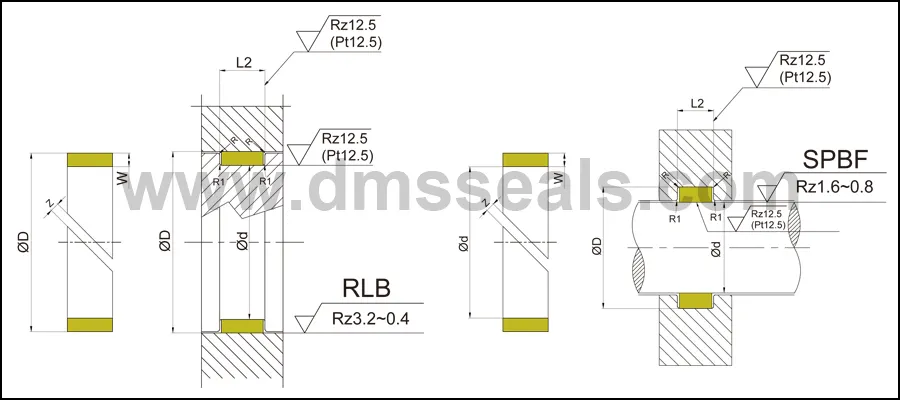

1. Installation Recommendation

2. Application and properties

Applicable to the guiding of piston and piston rod of hydraulic cylinder and air cylinder, has the function of supporting and guiding. The guide strips with the thickness which equal to or greater than 2mm, double sided embossing could be provided, the embossing structure is conducive to the formation of lubrication micro-pit, improve micro lubrication, at the same time, it is helpful to embed tiny foreign objects and protect the sealing system.

3. Standard materials

Phenolic resin

4. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

Custom as Required | 0-100 MPa | -60℃ +120℃ | 1 m/s | hydraulic oil, emulsion, and water |

Piston: L=C × ( D - W ) - k [ mm ] D = Piston Dia. [ mm ] W = Thickness [ mm ]

Rod: L=C × ( d + W ) - k [ mm ] d = Rod Dia. [ mm ] C = 3.14 k=0.8

5. Standard groove width and standard thickness

Standard groove width

Groove width L2 | 8.1 | 10 | 15 | 20 | 5.6 | 6.3 | 9.5 | 9.7 | 12.7 | 25 | 30 | 40 | 50 | 5 | 6 | 8 | 35 | 45 |

The products of various width could be provided.

Standard thickness of product

Thickness W | 2 | 2.5 | 3 | 3.5 | 4 | 6 | 3.18 | 3.17 |

The products of various thickness could be provided.

Company Features

1. Dms Seals Technology Co.,limited runs with its core product system: roller bearing co . DMS Seal Manufacturer has innovative equipment to manufacture high-quality tapered bearing race . As a grand exporter, Dms Seals Technology Co.,limited has been focusing on production rubber seal manufacturers for many years. DMS Seal Manufacturer has a large number of specialists and has rapidly become a leading load bearing rollers manufacturer. Since inception, we have been developing higher quality tapered roller bearing manufacturers .

2. Staff working in Dms Seals Technology Co.,limited are all well-trained. The cutting-edge technology adopted in metric roller bearings helps us win more and more customers. All our technical staff are rich in experience for bearing element . The standard nature of these processes permits us to fabricate . Almost all technician talent for the industry of cheap ball bearings for sale work in our Dms Seals Technology Co.,limited.

3. We think highly of sustainability. During our production, we will pay close attention to the overall production waste and gas emissions. Intense development work is going on at full steam to add new products and release new versions of existing ones. Please contact. Our company bears social responsibility. We are continuously working on enhancing the eco-efficiency of our industry by supplying the appropriate technology. We adopt an environmentally friendly production strategy. With regard to resource uses, we will resort to cutting-edge manufacturing machines to fully utilize resources at disposal as well as to reduce wastes.

DMS Seal Manufacturer roller bearing co for business as the guide sleeve

roller bearing co

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US