DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer ptfe O Ring Manufacturers with nbr or fkm o ring for pressure work and sliding high speed occasions

1. DMS Seal Manufacturer O Ring Manufacturers represents the finest workmanship in the market as it is manufactured using the leading technology. As a modern sealing technology company, DMS Seal manufacturer has a wealth of experience

2. Dms Seals Technology Co.,limited keeps service as top place to satisfy our customers. To reduce costs with high-efficiency work is the DMS's purpose

3. The product has the advantage of stable mechanical properties. Having been treated under extremely cold temperatures, its mechanical components are tensile enough to withstand extreme industrial conditions. Seal we produced has applications in a wide range of fields

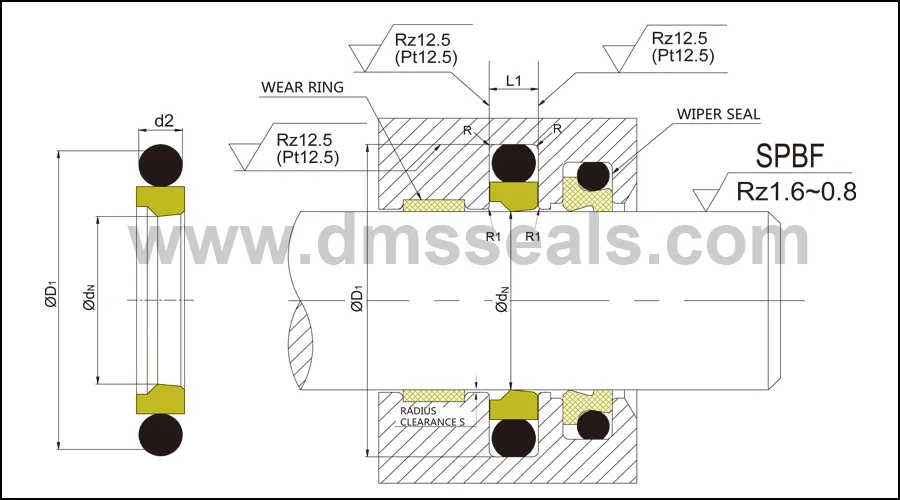

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation. Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

22 25 25 | 32.7 32.3 35.7 | 4.2 3.2 4.2 | GSJ22*32.7*4.2 GSJ25*32.3*3.2 GSJ25*35.7*4.2 | 26.57*3.53 26.64*2.62 29.74*3.53 |

28 30 32 | 38.7 40.7 42.7 | 4.2 4.2 4.2 | GSJ28*38.7*4.2 GSJ30*40.7*4.2 GSJ32*42.7*4.2 | 31.34*3.53 34.52*3.53 36.09*3.53 |

35 36 38 | 45.7 46.7 53.1 | 4.2 4.2 6.3 | GSJ35*45.7*4.2 GSJ36*46.7*4.2 GSJ38*53.1*6.3 | 37.69*3.53 40.87*3.53 43.82*5.33 |

40 40 42 | 50.7 55.1 57.1 | 4.2 6.3 6.3 | GSJ40*50.7*4.2 GSJ40*55.1*6.3 GSJ42*57.1*6.3 | 44.04*3.53 43.82*5.33 46.99*5.33 |

45 45 50 | 55.7 60.1 60.7 | 4.2 6.3 4.2 | GSJ45*55.7*4.2 GSJ45*60.1*6.3 GSJ50*60.7*4.2 | 47.22*3.53 50.17*5.33 53.57*3.53 |

50 55 56 | 65.1 70.1 66.7 | 6.3 6.3 4.2 | GSJ50*65.1*6.3 GSJ55*70.1*6.3 GSJ56*66.7*4.2 | 56.52*5.33 59.69*5.33 59.92*3.53 |

56 56 60 | 71.1 76.5 75.1 | 6.3 8.1 6.3 | GSJ56*71.1*6.3 GSJ56*76.5*8.1 GSJ60*75.1*6.3 | 59.69*5.33 62.87*6.99 66.04*5.33 |

Company Features

1. Dms Seals Technology Co.,limited is a professional manufacturer for producing O Ring Manufacturers in China. We are constantly expanding our business scope.

2. Dms Seals Technology Co.,limited has advanced production equipment and first-class management model.

3. Dms Seals Technology Co.,limited will provide a comprehensive hydraulic rod seals solution for our customers. Call now!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US