DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer pneumatic seal kit with nbr or fkm o ring for sale

1. Each DMS Seal Manufacturer is produced by our design department. They spend time exploring, testing and assessing a variety of materials and processes that fit the scope of this bedding work.

2. Fine workmanship has been adopted during the production of DMS Seal Manufacturer . It is fabricated under mold shaping or compression molding to achieve robust and stiff mechanical structure.

3. DMS Seal Manufacturer has been evaluated by process. It has been tested in terms of color, color fastness (friction test), and safety of accessories.

4. The model of DMS Seal Manufacturer is designed using computer aided software such as CAD. This design approach allows our production team to complete the model in a few hours.

5. The product is highly resistant to bacteria. It is made of anti-bacterial fabrics that keep clean and ventilated all the time.

6. This product is safe enough. Its fabrics are free of any toxic or chemical substances that would do harm to the human body.

7. This product is able to endure daily abuse. The fingernails, sharp objects, or steel wire brush can do nothing with it.

8. The product has excellent air permeability. Its fabrics have good moisture and sweat absorption performance to keep the body dry and ventilated.

9. The product is not likely to deform. All its weakest points have gone through a concentrated load test to ensure no structural damage occurs.

10. With customizable printing and shape, this product can always make an item beautifully packaged and be attractive to the audience.

11. The product greatly removes the giant need of workers for the production. In this way, it helps save costs on labor.

12. The product acts a significant role in improving productivity. It can greatly cut people's working time and burden, thus people will enhance their working potential.

D H8 | d h9 | L+0.2 | H |

˂96 | D-16.3 | 8 | 7.5 |

96-190 | D-20 | 10 | 9.5 |

191-380 | D-28 | 13 | 12.5 |

381-1000 | D-36 | 20 | 19.5 |

Application and properties

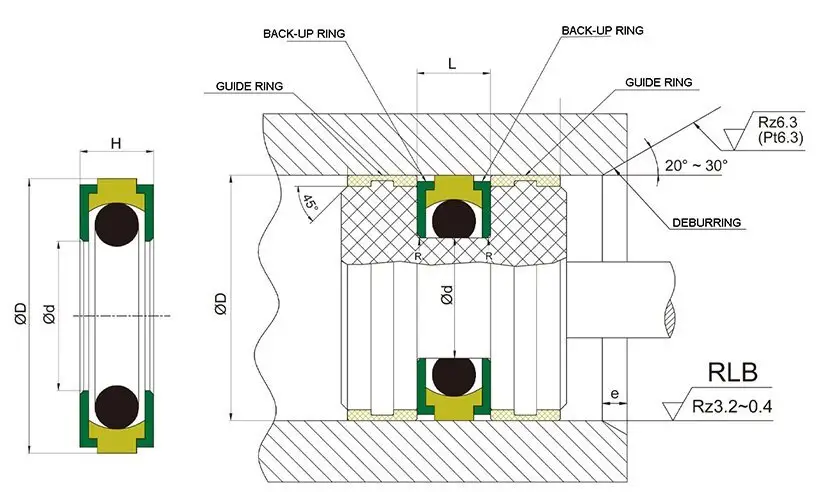

Apply to hydraulic piston sealing, Consisting of a seal ring, two L-shaped POM back-up rings and an acting force O-Ring. The back-up ring acts as a support and guide to ensure a tight sealing environment. High wear resistance, low friction, no crawling phenomenon, easy installation.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

L-Ring: POM / PA

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-45MPa | -30℃+100℃ | 1 m/s | hydraulic oil, flame retardant liquid, water and others |

D H8 | d h9 | H | L | e | Order No. |

40 | 23.2 | 7.5 | 8 | 7 | DGDA40*23.2*7.5 |

56 | 39.2 | 7.5 | 8 | 7 | DGDA56*39.2*7.5 |

70 | 53.2 | 7.5 | 8 | 7 | DGDA70*53.2*7.5 |

85 | 68.2 | 7.5 | 8 | 7 | DGDA85*68.2*7.5 |

100 | 80 | 9.5 | 10 | 10 | DGDA100*80*9.5 |

115 | 95 | 9.5 | 10 | 10 | DGDA115*95*9.5 |

130 | 110 | 9.5 | 10 | 10 | DGDA130*110*9.5 |

145 | 125 | 9.5 | 10 | 10 | DGDA145*125*9.5 |

160 | 140 | 9.5 | 10 | 10 | DGDA160*140*9.5 |

190 | 170 | 9.5 | 10 | 10 | DGDA190*170*9.5 |

220 | 192 | 12.5 | 13 | 12 | DGDA220*192*12.5 |

Company Features

1. As a pioneer the pneumatic seal kit industry, DMS Seal Manufacturer has been expanding its own production capacity. Dms Seals Technology Co.,limited is a company that has famous brands, networks and management expertise. DMS Seal Manufacturer has gained increasing popularity in the safety seal piston ring company market. DMS Seal Manufacturer is dedicated to offering the reliable hallite hydraulic seals and considerate service.

2. Our factory is home to state-of-the-art operation facilities. These machines allow us to manufacture products at the fastest speed, thus our quick delivery time can be guaranteed. Our factory has state-of-the-art manufacturing facilities. They allow us to be capable of meeting the challenges of technology, quality conformance, and delivery while ensuring cost competitiveness. Our factory is blessed with a full line of cutting-edge production facilities and testing equipment. They are extremely useful in enhancing productivity and product quality, which gives us more confidence in providing clients quality products. Our factory has state-of-the-art machinery and equipment. They are well-maintained and cared for, supporting prototype, and both low & high volume production quantities.

3. We strive to hold up the highest ethical and professional standards in our organization and we are highly accountable to our customers. We will always promote customer-centricity. All of the employees especially members of the customer service team are required to take part in customer service training, aiming to strengthen their empathy and a better understanding of customers' needs. Integrity is the core value of our company. We aim to demonstrate honesty, respect for others and trustworthiness in all we do.

DMS Seal Manufacturer pneumatic seal kit with nbr or fkm o ring for sale

pneumatic seal kit

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US