DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer piston seals with nbr or fkm o ring for sale1

1. The manufacturing process of DMS Seal Manufacturer piston seals is well-conducted by a professional production team. DMS Seals manufacturer owns a team of professional R&D group and skilled technicians

2. This product will effectively help align people's feet and finally significantly help correct their gait and improve their body posture. DMS Seals takes the lead in grasping the development trend of the industry

3. This product has passed through many international certifications. DMS Seals implements and optimizes its quality control systems

4. Our piston seals has complete product specifications and various models of rubber piston seals. Seal we produced has applications in a wide range of fields

5. piston seals is produced according to GB and IEC standards. DMS Seal manufacturer was established in 2008 and now has more than 10 years professional experience

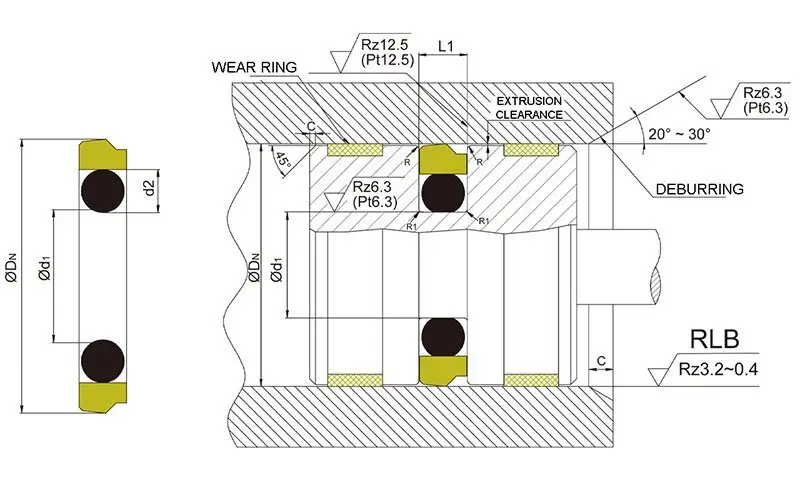

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-16.9 | 17-26.9 | -- | DN-4.9 | 2.2 | 0.4 | 0.30 | 0.20 | 0.15 | 1.78 |

17-26.9 | 27-59.9 | -- | DN-7.3 | 3.2 | 0.6 | 0.40 | 0.25 | 0.15 | 2.62 |

27-59.9 | 60-199.9 | 17-26.9 | DN-10.7 | 4.2 | 1.0 | 0.50 | 0.30 | 0.20 | 3.53 |

60-199.9 | 200-255.9 | 27-59.9 | DN-15.1 | 6.3 | 1.3 | 0.70 | 0.40 | 0.25 | 5.33 |

200-255.9 | 256-669.9 | 60-199.9 | DN-20.5 | 8.1 | 1.8 | 0.80 | 0.60 | 0.35 | 7.00 |

256-669.9 | 670-999.9 | 200-669.9 | DN-24.0 | 8.1 | 1.8 | 0.90 | 0.70 | 0.40 | 7.00 |

670-999.9 | -- | 256-669.9 | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | 1000-2000 | -- | DN-28.0 | 9.5 | 2.5 | 1.00 | 0.80 | 0.60 | 8.40 |

-- | -- | 670-999.9 | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

1000-2700 | -- | -- | DN-38.0 | 13.8 | 3.0 | 1.20 | 0.90 | 0.60 | 12.00 |

Application and properties

Standard single acting sealing. Suitable for reciprocating environment, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are good, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

Standard materials

Sealing ring: filled PTFE

O-ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Width | Order No. | O-ring Dimension |

D H9 | d1 h9 | L1+0.2 | ||

9 | 4.1 | 2.2 | GSD9*4.1*2.2 | 3.68*1.78 |

15 | 10.1 | 2.2 | GSD15*10.1*2.2 | 9.25*1.78 |

20 | 12.7 | 3.2 | GSD20*12.7*3.2 | 12.37*2.62 |

27 | 16.3 | 4.2 | GSD27*16.3*4.2 | 15.47*3.53 |

32 | 24.7 | 3.2 | GSD32*24.7*3.2 | 23.47*2.62 |

36 | 25.3 | 4.2 | GSD36*25.3*4.2 | 24*3.53 |

40 | 29.9 | 4.2 | GSD40*29.3*4.2 | 28.17*3.53 |

50 | 39.3 | 4.2 | GSD50*39.3*4.2 | 37.70*3.53 |

55 | 44.3 | 4.2 | GSD55*44.3*4.2 | 44.04*3.53 |

63 | 47.9 | 6.3 | GSD63*47.9*6.3 | 46.99*5.33 |

70 | 59.3 | 4.2 | GSD70*59.3*4.2 | 56.74*3.53 |

80 | 64.9 | 6.3 | GSD80*64.9*6.3 | 62.87*5.33 |

90 | 74.9 | 6.3 | GSD90*74.9*6.3 | 72.39*5.33 |

95 | 74.5 | 8.1 | GSD95*74.5*8.1 | 73*7.0 |

110 | 94.9 | 6.3 | GSD110*94.9*6.3 | 91.44*5.33 |

Company Features

1. Dms Seals Technology Co.,limited is great at producing garnished piston seals with high performance.

2. Dms Seals Technology Co.,limited builds up a first-class hydraulic piston seals professional R&D team with numbers of technical personnel.

3. Dms Seals Technology Co.,limited's aim is to be the first company to break into emerging markets. Get price!

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US