DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer o ring seal manufacturers glyd ring

- Based on customer demand, Dms Seals insists on seeking excellence and taking innovation, so as to provide consumers with better services.

1. Stylish looking: the appearance of DMS Seal Manufacturer is appealing, giving a sense of fashion. Its stylish looking allows users to be delightful to use.

2. DMS Seal Manufacturer has passed the workmanship assessment. It is evaluated in terms of fabrics, stitching, construction, attachments, and accessories.

3. DMS Seal Manufacturer is precisely manufactured by adopting laser machines, CNC machines, a full line of precision press brakes, and vertical machines.

4. The product features reliable chemical resistance. It has excellent resistance to a wide range of chemicals including chlorinated hydrocarbons, fuels, and many acids.

5. The product is highly chemical resistant. It is treated with a protective chemical coating or with protective paintwork to prevent corrosion.

6. The product has good colorfastness. Its PVC coating not only protects against the rain but also keeps it from being damaged by UV.

7. The product is durable enough. It is made of 304 stainless steel and formed by automated laser welding, thus there is no possibility of damage.

8. The product features the necessary ductility. It can be drawn or plastically deformed without fracture when exposed to a tensile load.

9. The product is widely applied to in the market for its huge economic potential.

10. The product has good stability and reliability and long service life.

11. The market prospect of the product is promising as it can deliver great economic benefits, favoured by customers.

12. The product has earned good reputation and trust from clients at home and abroad.

13. The product, meeting customer's practical requirements perfectly, has enormous market potential.

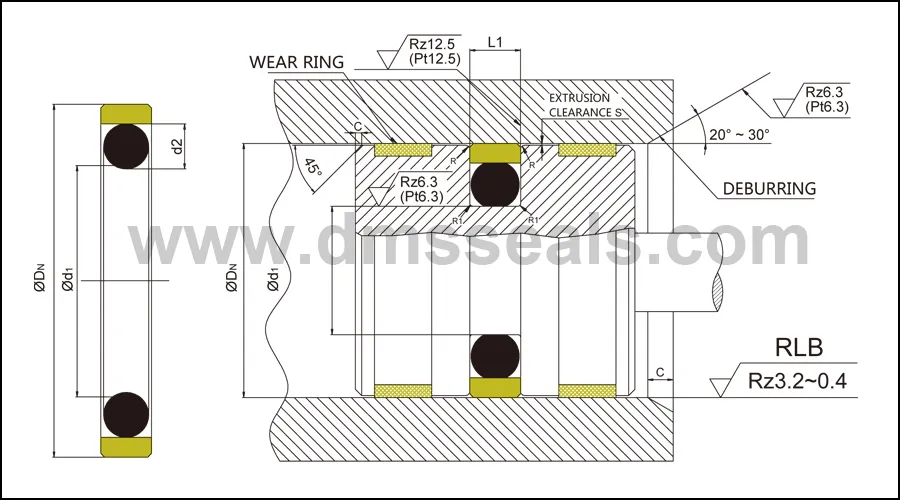

1. Installation Recommendation

2. Installation Sizes

Bore Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

8-14.9 | 15-39.9 | - | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 | |

15-39.9 | 40-79.9 | - | DN-7.5 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

40-79.9 | 80-132.9 | 15-39.9 | DN-11.0 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

80-132.9 | 133-329.9 | 40-79.9 | DN-15.5 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

133-329.9 | 330-699.9 | 80-132.9 | DN-21.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

330-669.9 | 670-99.9 | 133-329.9 | DN-24.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

670-999.9 | 330-669.9 | DN-28.0 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 | |

≥1000 | ≥1000 | ≥1000 | DN-38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Standard double acting seal. Suitable for reciprocating motion, allowing larger extrusion clearances, has wide application. Dynamic and static sealing property are excellent, be able to work in dusty condition. Low friction, simple groove, strong adaptability to work conditions.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water and others |

6. Installation Dimensions

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

DN H9 | d1 h9 | L1+0.2 | ||

8 10 12 | 3.1 5.1 7.1 | 2.2 2.2 2.2 | GSF8*3.1*2.2 GSF10*5.1*2.2 GSF12*7.1*2.2 | 2.90*1.78 4.80*1.8 6.70*1.8 |

14 15 15 | 9.1 10.1 7.5 | 2.2 2.2 3.2 | GSF14*9.1*2.2 GSF15*10.1*2.2 GSF15*7.5*3.2 | 8.75*1.8 7.59*2.62 8.75*1.8 |

16 16 18 | 11.1 8.5 13.1 | 2.2 3.2 2.2 | GSF16*11.1*2.2 GSF16*8.5*3.2 GSF18*13.1*2.2 | 10.82*1.78 7.59*2.62 12.42*1.78 |

18 20 20 | 10.5 15.1 12.5 | 3.2 2.2 3.2 | GSF18*10.5*3.2 GSF20*15.1*2.2 GSF20*12.5*3.2 | 9.19*2.62 14.00*1.78 12.37*2.62 |

24 24 25 | 19.1 16.5 17.5 | 2.2 3.2 3.2 | GSF24*19.1*2.2 GSF24*16.5*3.2 GSF25*17.5*3.2 | 18.77*1.78 15.54*2.62 17.12*2.62 |

25 28 28 | 14 20.5 17 | 4.2 3.2 4.2 | GSF25*14*4.2 GSF28*20.5*3.2 GSF28*17*4.2 | 13.87*3.53 20.29*2.62 15.47*3.53 |

30 30 32 | 22.5 19 24.5 | 3.2 4.2 3.2 | GSF30*22.5*3.2 GSF30*19*4.2 GSF32*24.5*3.2 | 21.89*2.62 26.70*1.78 23.47*2.62 |

Company Features

1. After years of continuous efforts on the design and manufacture of , Dms Seals Technology Co.,limited has been remarked as a strong manufacturer and supplier. With years of experience and expertise in designing and manufacturing of , Dms Seals Technology Co.,limited has taken its place among manufacturers in the industry. Dms Seals Technology Co.,limited has been focusing exclusively on the manufacture of o ring seal manufacturers for years. Our ability in manufacturing is recognized among competitors.

2. technology is not only good for improvement of quality but also quantity for metric mechanical seals . To ensure quality of packing seal vs mechanical seal , Dms Seals Technology Co.,limited introduced a full set of quality control system. There is a great progress in quality for shaft seals for pumps with the help of technology. DMS Seal Manufacturer is able to provide multiple options for customers to choose different types of rubber seal strip suppliers . Our advanced technology not only assures quality for manufacture of seals but also cut cost for it.

3. We take immense pride in providing the best service. We work hard to ensure that you are well taken care of when you choose us. Your satisfaction is our main priority and we strive to prove that every day. Please contact. We bear social responsibilities. We continually improve our environmental performance and encouraging our suppliers and partners to do the same. We treat our environment responsibly. We using technological advances and innovative solutions to minimize the negative impact of our operations on the environment. We bear social responsibilities. Everyone in the company is called upon to save resources in their field and to develop and implement new ideas to achieve this.

DMS Seal Manufacturer o ring seal manufacturers glyd ring

o ring seal manufacturers

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

export@dmsseals.com

PAY ATTENTION TO US