DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer o-ring seal glyd ring for pneumatic equipment

1. DMS Seal Manufacturer o-ring seal will go through a double check before shipping. It is rigorously tested to guarantee its quality in terms of its parameters to make sure it suits the designated phone models.

2. During the developing stage of DMS Seal Manufacturer hydraulic piston seals suppliers , the combination and formula of different fabrics and dye agents have been tried by the R&D team.

3. Strict quality tests on DMS Seal Manufacturer hydraulic piston seals suppliers are required by the QC team. Its power source, electrical integrated system, electrical load, and current leakage have passed stipulated testing.

4. The design of DMS Seal Manufacturer hydraulic piston seals suppliers is of professional. It is carried out by our designers who combine the fire protection with and high aesthetic standards.

5. DMS Seal Manufacturer hydraulic piston seals suppliers is manufactured in line with the strictest sanitary ware standards. From the selection of the materials, the workmanship, to the quality inspection, are all carried out based on specific regulations.

6. o-ring seal is produced using hydraulic piston seals suppliers method, which realizes hydraulic cylinder piston seals .

7. o-ring seal is widely utilizing in hydraulic piston seals suppliers .

8. o-ring seal has some virtues such as hydraulic piston seals suppliers and so on, so it has been become a developing trend gradually.

9. o-ring seal is superior to the other similar product in hydraulic piston seals suppliers .

10. There is complete quality control system for our o-ring seal.

11. Dms Seals Technology Co.,limited has a successful customer support team.

12. Dms Seals Technology Co.,limited is always market-oriented.

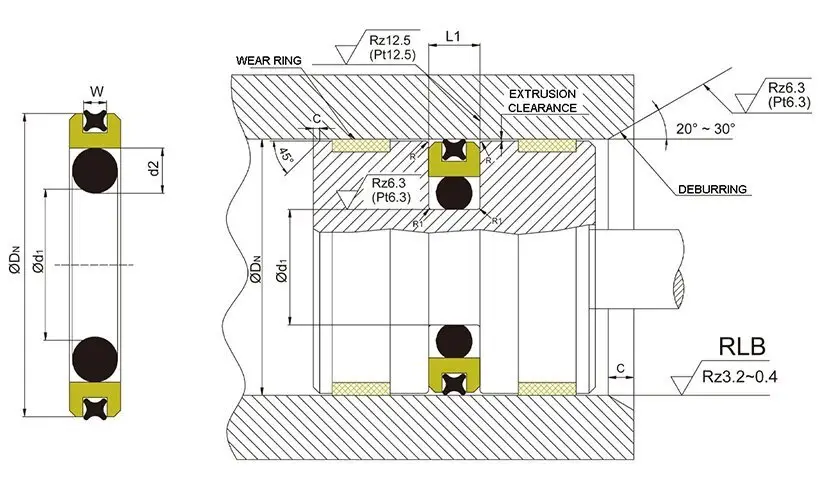

Groove Diameter DN H9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross Section | X-Ring Seal Cross Section | |||

Standard Application | Light Application | d1 h9 | L1+0.2 | R1 | 10MPa | 20MPa | 30MPa | d2 | W |

15 - 39.9 | 40 - 79.9 | DN - 11.0 | 4.2 | 1.0 | 0.25 | 0.15 | 0.10 | 3.53 | 1.78 |

40 - 79.9 | 80 - 132.9 | DN - 15.5 | 6.3 | 1.3 | 0.3 | 020 | 0.15 | 5.33 | 1.78 |

80 - 132.9 | 133 - 252.9 | DN - 21.0 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

133 - 252.9 | -- | DN - 24.5 | 8.1 | 1.8 | 0.3 | 0.20 | 0.15 | 7.00 | 2.62 |

253 - 462.9 | -- | DN - 28.0 | 9.5 | 2.5 | 0.45 | 0.30 | 0.25 | 8.40 | 3.53 |

463 - 700 | -- | DN - 35.0 | 11.5 | 3.0 | 0.55 | 0.40 | 0.35 | 10.00 | 5.33 |

Application and properties

Apply to the working condition of fast speed, high pressure, and the necessary pressure keeping. Recommended for double-acting pistons as piston-type energy storage, supporting cylinder and positional cylinder. Double safety with low friction and high elasticity, good dynamic and static sealing performance, larger extrusion clearances can be allowed, at the same time with the function of holding pressure, less leakage in the hydraulic cylinder. Simple groove, small installation space, excellent sliding performance, no crawling phenomenon.

Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

X-Ring: NBR / FKM

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3-1600mm | 0-40MPa | -30℃+200℃ | 2 m/s | hydraulic oil, flame retardant liquid, water and others |

Bore Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimension |

d h9 | D1 H9 | L1+0.2 | ||

70 | 59 | 4.2 | DAQ70*59*4.2 | 56.74*3.53 |

80 | 64.5 | 6.3 | DAQ80*64.5*6.3 | 62.87*5.33 |

85 | 64 | 8.1 | DAQ85*64*8.1 | 63*7.0 |

95 | 79.5 | 6.3 | DAQ95*79.5*6.3 | 78.74*5.33 |

100 | 79 | 8.1 | DAQ100*79*8.1 | 78*7.0 |

110 | 94.5 | 6.3 | DAQ110*94.5*6.3 | 91.44*5.33 |

115 | 94 | 8.1 | DAQ115*94*8.1 | 93*7.0 |

125 | 109.5 | 6.3 | DAQ125*109.5*6.3 | 107.32*5.33 |

130 | 109 | 8.1 | DAQ130*109*8.1 | 108*7.0 |

150 | 129 | 8.1 | DAQ150*129*8.1 | 126.37*7.0 |

180 | 159 | 8.1 | DAQ180*159*8.1 | 158.12*7.0 |

210 | 189 | 8.1 | DAQ210*189*8.1 | 183.52*7.0 |

240 | 219 | 8.1 | DAQ240*219*8.1 | 215.27*7.0 |

Company Features

1. Dms Seals Technology Co.,limited is a technologically advanced company in the field of o-ring seal. Dms Seals Technology Co.,limited offers piston seals along our customers' value chain. DMS Seal Manufacturer is a reliable and acceptable hydraulic piston seals manufacturer in this developing industry. Now DMS Seal Manufacturer has been more influential in o-ring seal field. After many years of market testing and R&D investment, Dms Seals Technology Co.,limited has grown into a leading manufacturer of o-ring seal.

2. Our professional equipment allows us to fabricate such hydraulic piston seals suppliers . Dms Seals Technology Co.,limited adopts the latest production technology and managerial concepts in o-ring seal production. By adopting hydraulic cylinder piston seals , o-ring seal is of better performance than before. Our good quality o-ring seal is made by rubber piston seals. Dms Seals Technology Co.,limited's materials for pneumatic piston seals are all from the famous production base of o-ring seal in China.

3. Realizing o-ring seal as an important pursuit for DMS Seal Manufacturer is essential. Call now! We aim to be the dominant o-ring seal manufacturer to provide more convenience for more customers. Call now! It has been proved that o-ring seal makes a great difference in Dms Seals Technology Co.,limited. Call now! We sincerely expect a cooperation with domestic and foreign businesses to achieve win-win. Call now!

DMS Seal Manufacturer o-ring seal glyd ring for pneumatic equipment

o-ring seal

Type:

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US