DMS SEALS TECHNOLOGY CO.,LIMITED

The Professional Sealing Solution Supplier(O Ring Suppliers & Oil Seal Manufacturers).

DMS Seals - Hydraulic Seals and Oil Ring Seals Manufacturer & Supplier

DMS Seal Manufacturer O Ring Manufacturers with nbr or fkm o ring to high and low speed

- Dms Seals has a complete and mature service team to provide excellent services for customers and seek mutual benefit with them.

1. DMS Seal Manufacturer O Ring Manufacturers has gone through a series of tests. These tests include electric safety tests for obtaining national and international approvals, noise emission measurements, and risk analysis.

2. DMS Seal Manufacturer rod seal catalogue will be seriously checked for its materials and parts. Its electric components will be inspected in line with a restriction of the use of hazardous and heavy metals, such as hexavalent chromium (Cr6+), Polybrominated Diphenyl Ethers (PBDE), and polybrominated biphenyl (PBB).

3. The production procedures of DMS Seal Manufacturer rod seal catalogue are professional. It is treated with winding, drawing in, looming, shedding, and beating-up processes which comply with the requirements of the textile industry.

4. Our QC team will double check to ensure the quality of this product.

5. DMS Seal Manufacturer sets up an integrated series of quality assurance system to ensure its quality.

6. Comprehensive quality control is carried out to ensure the product meets with all related quality standards.

7. Compared with the competitors, the product is more reliable in quality and performance.

8. People who wear this product have the same comment on it: it is soft and comfortable. Not itchy or too thick.

9. This product will definitely make high-quality and comfortable shoes that can make feet devoid of any bruises and discomfort.

10. By wearing this product, people no longer have to worry about experience allergic reactions. It contains no chemical dyes and it won’t harm people.

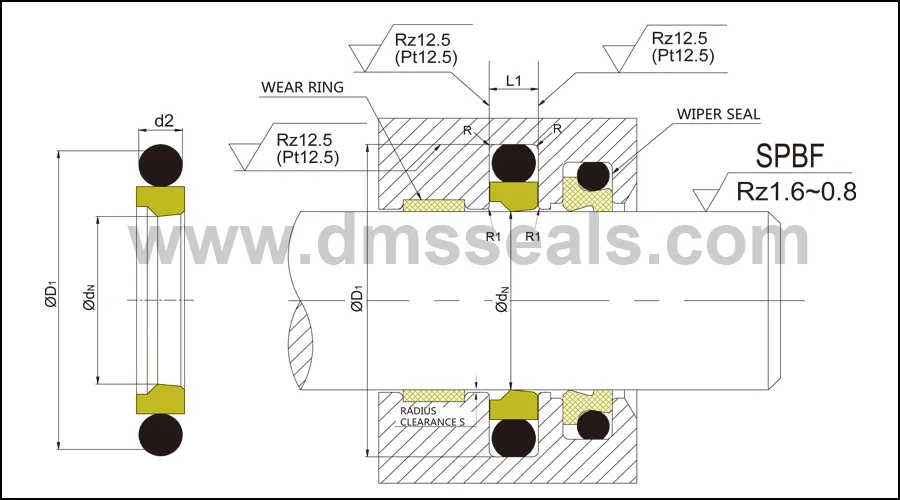

1. Installation Recommendation

2. Installation Sizes

Rod Diameter dN h9 | Groove Diameter | Groove Width | Radius | Radial Clearance S max. | O-Ring Cross-Section | ||||

Standard Application | Light Application | Heavy Duty Application | D1 H9 | L1+0.2 | R1 | 10MPa | 20MPa | 40MPa | d2 |

3-7.9 | 8-18.9 | - | dN+4.9 | 2.2 | 0.4 | 0.3 | 0.20 | 0.15 | 1.78 |

8-18.9 | 19-37.9 | - | dN+7.3 | 3.2 | 0.6 | 0.4 | 0.25 | 0.15 | 2.62 |

19-37.9 | 38-199.9 | 8-18.9 | dN+10.7 | 4.2 | 1.0 | 0.4 | 0.25 | 0.20 | 3.53 |

38-199.9 | 200-255.9 | 19-37.9 | dN+15.1 | 6.3 | 1.3 | 0.5 | 0.30 | 0.20 | 5.33 |

200-255.9 | 256-649.9 | 38-199.9 | dN+20.5 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

256-649.9 | 650-999.9 | 200-255.9 | dN+24.0 | 8.1 | 1.8 | 0.6 | 0.35 | 0.25 | 7.00 |

650-999.9 | ≥1000.0 | 256-649.9 | dN+27.3 | 9.5 | 2.5 | 0.7 | 0.50 | 0.30 | 8.40 |

≥1000.0 | - | 650-999.9 | dN+38.0 | 13.8 | 3.0 | 1.0 | 0.70 | 0.60 | 12.00 |

3. Application and properties

Applicable to high and low speed reciprocating motion and high pressure system cylinder rod sealing. Good dimensional stability, not affected by temperature, low friction, strong corrosion resistance, could work in the situation with or without lubrication, easy installation. Meet the standards of GB/T 15242.1-94 and GB/T 15242.3-94.

4. Standard materials

Sealing ring: filled PTFE

O-Ring: NBR / FKM

5. Working Conditions

Working Conditions | ||||

Diameter Range | Pressure Range | Temperature Range | Speed | Medium |

3 - 1600mm | 0 - 60MPa | -45℃ +200℃ | 15 m/s | hydraulic oil, flame retardant liquid, water, gas |

6. Installation Dimensions

Rod Dia. | Groove Dia. | Groove Width | Order No. | O-Ring Dimensions |

dN h9 | D1 H9 | L1+0.2 | ||

20 20 22 | 27.3 30.7 29.3 | 3.2 4.2 3.2 | GSJ20*27.3*3.2 GSJ20*30.7*4.2 GSJ22*29.3*3.2 | 21.89*2.62 23.39*3.53 23.47*2.62 |

22 25 25 | 32.7 32.3 35.7 | 4.2 3.2 4.2 | GSJ22*32.7*4.2 GSJ25*32.3*3.2 GSJ25*35.7*4.2 | 26.57*3.53 26.64*2.62 29.74*3.53 |

28 30 32 | 38.7 40.7 42.7 | 4.2 4.2 4.2 | GSJ28*38.7*4.2 GSJ30*40.7*4.2 GSJ32*42.7*4.2 | 31.34*3.53 34.52*3.53 36.09*3.53 |

35 36 38 | 45.7 46.7 53.1 | 4.2 4.2 6.3 | GSJ35*45.7*4.2 GSJ36*46.7*4.2 GSJ38*53.1*6.3 | 37.69*3.53 40.87*3.53 43.82*5.33 |

40 40 42 | 50.7 55.1 57.1 | 4.2 6.3 6.3 | GSJ40*50.7*4.2 GSJ40*55.1*6.3 GSJ42*57.1*6.3 | 44.04*3.53 43.82*5.33 46.99*5.33 |

45 45 50 | 55.7 60.1 60.7 | 4.2 6.3 4.2 | GSJ45*55.7*4.2 GSJ45*60.1*6.3 GSJ50*60.7*4.2 | 47.22*3.53 50.17*5.33 53.57*3.53 |

50 55 56 | 65.1 70.1 66.7 | 6.3 6.3 4.2 | GSJ50*65.1*6.3 GSJ55*70.1*6.3 GSJ56*66.7*4.2 | 56.52*5.33 59.69*5.33 59.92*3.53 |

56 56 60 | 71.1 76.5 75.1 | 6.3 8.1 6.3 | GSJ56*71.1*6.3 GSJ56*76.5*8.1 GSJ60*75.1*6.3 | 59.69*5.33 62.87*6.99 66.04*5.33 |

Company Features

1. Among many competitors, Dms Seals Technology Co.,limited is one of the most competitive ones. We center on the development and production of rod seal catalogue . Dms Seals Technology Co.,limited has come a long and far way in developing and manufacturing hydraulic rod seals online . We have made ourselves well known to the market. For years, Dms Seals Technology Co.,limited has been advancing the development, design, and production of O Ring Manufacturer

CONTACT US

TEL: +86-757-86235767

Contact Person: Teresa Chen

E-mail:

dms@dmsseals.com

PAY ATTENTION TO US